5 How to Control the Frequency Converter

5.1 PDO Communication

The VLT

®

AutomationDrive uses the following profiles:

•

Frequency converter profiles

•

CANopen DS 402 profile

For each of the two profiles there is a set of SDO objects

that is only accessible if the profile is activated in

8-10 Control Word Profile

. The change will first be active at

the next power up. The PDO communication has to be

configured, where a subset of SDOs can be mapped into

PDOs for cyclic communication.

PDO communication is reserved for high speed cyclic

access to parameters for control and status of the

frequency converter. The PLC sends out process control

data, and the frequency converter responds with a PDO

containing process status data. In the Danfoss POWERLINK

interface both PDOs can be freely be configured.

Select the signals for transmission from the master to the

frequency converter via the PLCs configuration tool.

12-21 Process Data Config Write

,

12-22 Process Data Config

Read

and

12-23 Process Data Config Write Size

will be set

from the PLC and can be used to control if the configu-

ration has been sent correctly from the PLC.

The POWERLINK option has only one PDO available: PDO

23. The PDO 23 is flexible in size and is adjustable to fit all

needs (max. 10 PCDs). The selection is made in the master

configuration and is then automatically downloaded to the

frequency converter during the transition from Init to Pre-

Op. No manual setting of PPO types in the frequency

converter is required.

Selection

[1] Standard telegram 1

is equivalent to PDO 23.

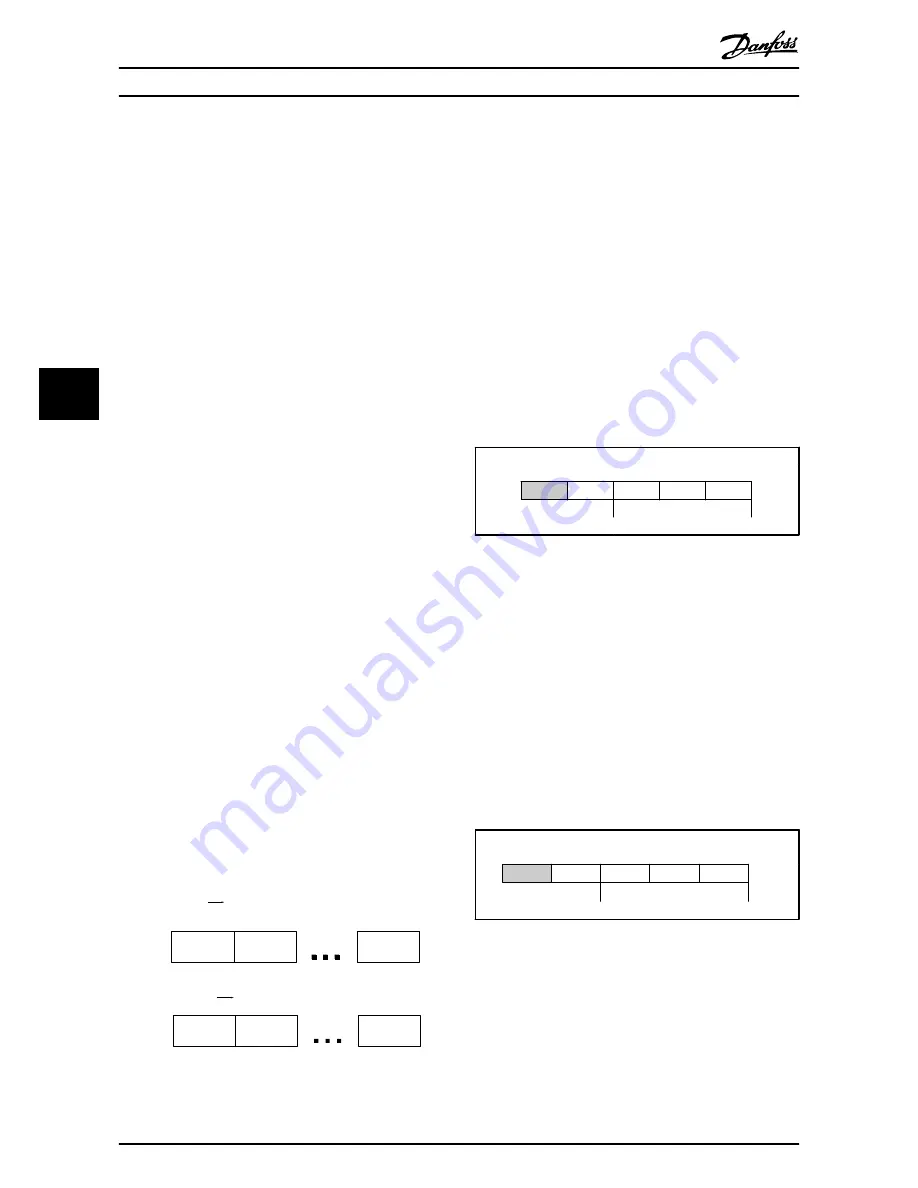

Receive PDOs (PLC

Drive)

Transmit PDOs (Drive

PLC)

PCD 9

write

PDO 23

PCD 0

CTW

PCD 1

REF

PCD 9

read

PCD 0

STW

PCD 1

MAV

PDO 23

130BC177.10

Illustration 5.1 Standard Telegram

5.2 Process Data

Use the process data part of the PDO for controlling and

monitoring the frequency converter via the POWERLINK.

5.2.1 Process Control Data

The example in

Table 5.1

shows control and reference sent

from the PLC to the frequency converter, and status word

and main actual value sent from the frequency converter

to the PLC.

Master to slave

0

1

2

......

9

CTW

MRV

PCD

......

PCD

PCD write

Table 5.1 Process Control Data (PCD)

PCD 0 contains a 16-bit control word where each bit

controls a specific function of the frequency converter, see

5.3 Control Profile

. PCD 1 contains a 16-bit speed set point

in percentage format. See

5.2.3 Reference Handling

.

The content of PCD 2 to PCD 9 is read only.

5.2.2 Process Status Data

Process data sent from the frequency converter contain

information about the current state of the frequency

converter.

Slave to master

0

1

2

......

9

STW

MAV

PCD

......

PCD

PCD read

Table 5.2 Process Status Data

PCD 0 contains a 16-bit status word where each bit

contains information regarding a possible state of the

frequency converter.

PCD 1 contains per default the value of the current speed

of the frequency converter in percentage format (see

5.2.3 Reference Handling

).

How to Control the Frequenc...

MCA 123 POWERLINK Operating Instructions

14

MG92C102 - VLT

®

is a registered Danfoss trademark

5

5