Cascade Controller Option

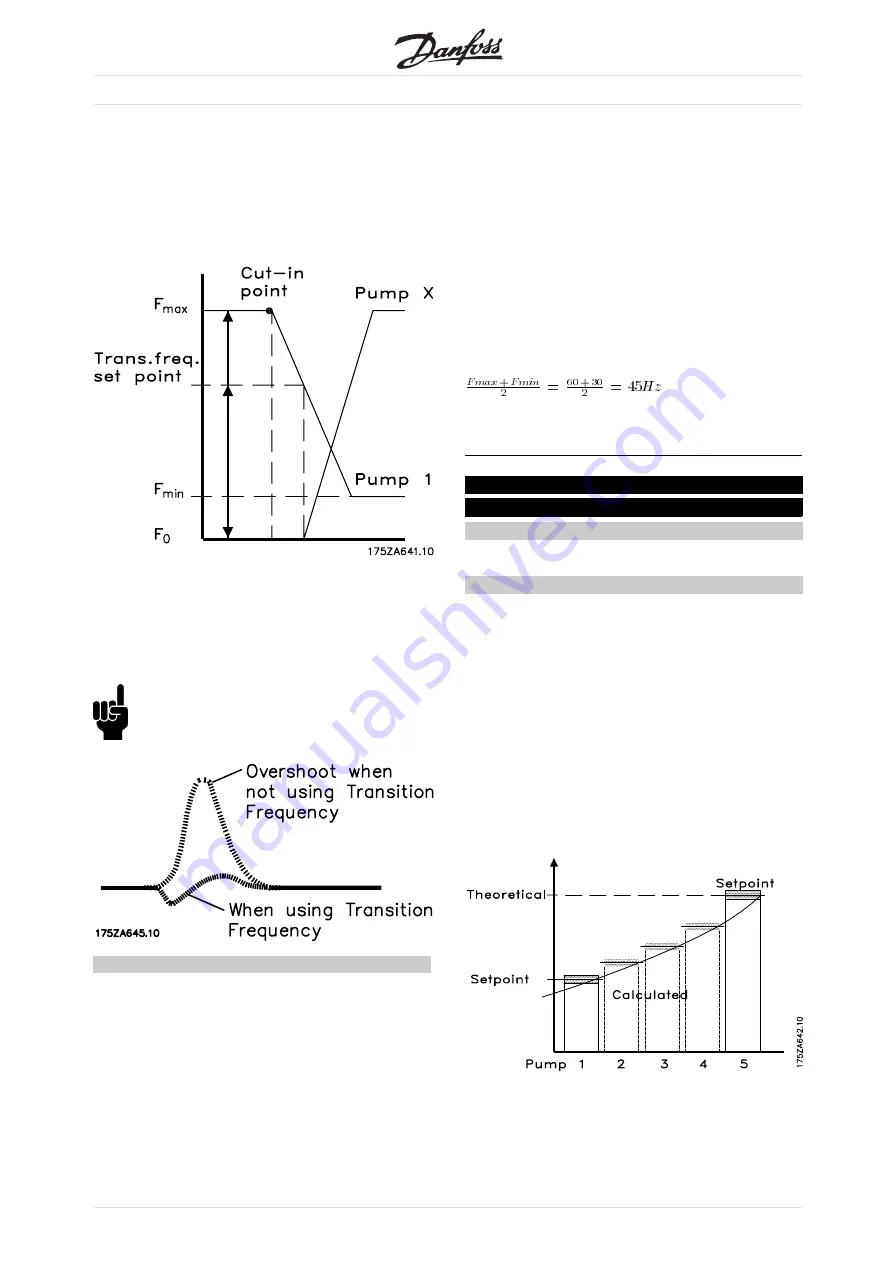

The instant effect of the fixed speed pump creates

a momentary overpressurization until the adjustable

speed pump decelerates. This is undesirable in

most situations. To avoid this, this drive can be

programmed to decelerate to a transition frequency

before starting the fixed speed pump.

The opposite process occurs during destaging

where a momentary pressure drop is avoided by

increasing the speed of the adjustable speed pump.

Therefore, set a transition frequency roughly half-way

between minimum and maximum frequency.

NB!:

Ensure that the transmission frequency is set

within the minimum frequency and maximum

set in parameters 201 and 202.

Description of choice:

Adjust the transition frequency to the best compromise

to prevent momentary pressure overshoot and a

pressure drop during transition. A very low value for

the transition frequency might cause the check valve

at the discharge of a variable speed pump to close

during the transition, which could add pressure in the

system. Ensure that the transition frequency setting

allows the check valve to remain open.

Adjust the transition frequency to the best compromise

to prevent momentary pressure overshoot and a

pressure drop during transition. A very low value for

the transition frequency might cause the check valve

at the discharge of a variable speed pump to close

during the transition, which could add pressure in the

system. Ensure that the transition frequency setting

allows the check valve to remain open.

Example:

Maximum frequency (F

max

) = 60Hz

Minimum frequency (F

min

)= 30Hz

Transistion frequency to be programmed exactly

F

max

and F

min

Then, transition frequency = 45/F

max

= 45/60 =75%

Quick Menu 028 Par. 418 Setpoint 1

(SETPOINT 1)

Value:

Feedback Min. to Feedback Max

✭

0.000

Function:

The default feedback process is used when a

pressure feedback signal is measured at the outlet

of the pumps. The cascade controller uses the

feedback to estimate the setpoint required at

various rates of flow. All other reference signals

are ignored. Setpoint 1 is the minimum pressure

required when the system is running with only the

adjustable frequency drive operating at full speed.

Setpoint 1 is a theoretical value that the cascade

controller uses as an internal reference to calculate

pressure loss in the system under minimum load.

The controller adjusts the internal reference based

upon the number of pumps in operation.

The range is determined by Quick Menu item 14

(parameter 413,

Minimum Feedback

) and Quick Menu

item 015 (parameter 414,

Maximum Feedback

).

When the pressure feedback signal originates at

the far end of the system, the drive does not

need to compensate for system pressure changes

MG.60.I3.02 - VLT is a registered Danfoss trademark

42