FXDQ-SPV1 EDTFVN391825

31

3P347455-11H

6

(2) When the pipe work is completed, please confirm

whether any air is leaked out.

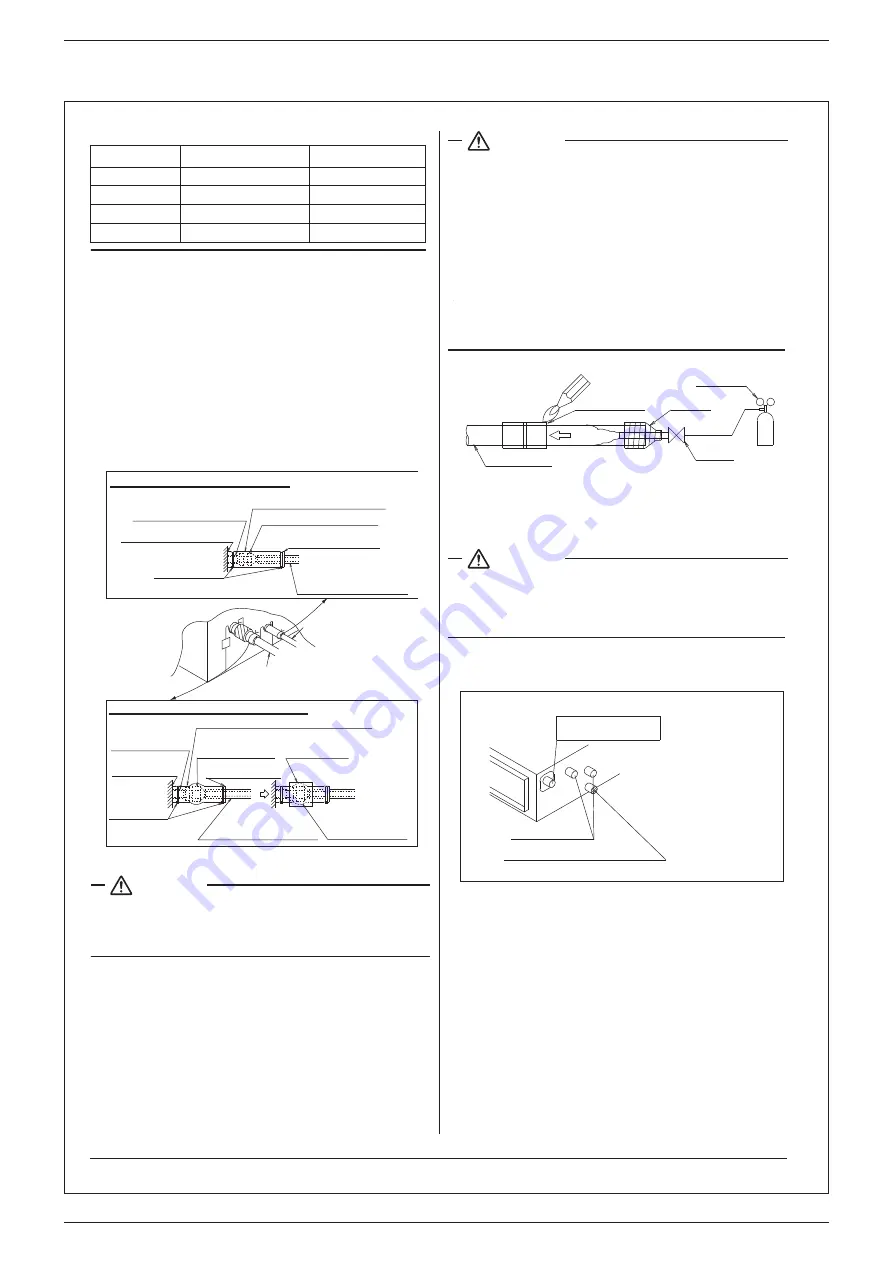

Heat insulation of the pipe on the liquid side

Heat insulation piece for

the pipe (Main unit side)

Heat insulation piece (3) for the

connector (Accessory)

Flare nut connection section

Close firmly to the unit body

The connecting seam

facing upward

Main unit

Banding tie (9)

(Accessory)

Heat insulation piece for

the pipe (supplied on site)

Pipe on the liquid side

Pipe on the air supply side

Heat insulation of the pipe on the air supply side

Heat insulation

piece for the pipe

(main unit side)

Heat insulation piece (4) for the connector

(Accessory)

Flare nut

connection section

The connecting

seam facing upward

Middle seal (6)

(Accessory)

Close firmly to

the unit body

Main unit

Banding tie (9)

(Accessory)

Heat insulation piece for

the pipe (supplied on site)

Wrap on the

flare nut connector.

Fig. 8

Table 2

Pipe dimension

Angle to be further tightened

Recommended length

of the tool arm

60 to 90 degrees

60 to 90 degrees

30 to 60 degrees

30 to 60 degrees

About 150 mm

About 200 mm

About 250 mm

About 300 mm

Ø 6.4 (1/4”)

Ø 9.5 (3/8”)

Ø 12.7 (1/2”)

Ø 15.9 (5/8”)

(3) When it is checked that no air is leaked out, please

refer to Fig. 8 to properly insulate the pipe

connections with heat insulation material.

·

When carrying out heat insulation work, please use

the supplied heat insulation piece (3) (4) for the pipe

of the liquid side and the air supply side. In addition,

the connecting seams of the heat insulation piece (3)

and (4) for the connector shall face upward. (Please

use banding tie (9) to clamp both ends.)

·

Please use the middle seal (6) to wrap the surface of

the heat insulation piece (4) for the connector on the

pipe of the air supply side. (The flare nut section)

The pipe supplied on site must be heat insulated to the

connecting section of the pipe. In case that the pipe is

exposed, condensate can occur, and injury from burning

can also happen if touched.

CAUTION

·

Before welding the refrigerant pipe, please firstly carry

out nitrogen exchange, or when welding (Caution 2),

fill in nitrogen (Caution 1) in the refrigerant pipe, and

finally use the flare to connect to the indoor unit.

(Refer to Fig. 9)

CAUTION

1. In case that nitrogen is filled into the pipe when welding,

a relief valve shall be used to control the pressure to

0.02 MPa (0.2 kgf/cm

2

) (as if breeze flows along your

cheek).

2. When welding the connection section of the refrigerant

pipe, never use any welding flux. Please use phosphorus

and bronze brazing material (BCuP-2: JIS Z 3264/

BCu93P-710/795: ISO 3677) which does not need

welding flux. (In case that any welding flux containing

chlorine is used, the pipe can be corroded; and in case

that any welding flux containing fluorin is used, the ester

oil or ether oil can be deteriorated, and the refrigerant pipe

system can be further influenced.)

Welding position

Relief valve

Wrapping

Nitrogen

Nitrogen

Refrigerant pipe

Manual

valve

Fig. 9

7. DRAIN PIPING WORK

CAUTION

·

The connecting interface of the water drainage pipe

varies depending on different types, so please confirm

the name of the type, and use the installation method

suitable for the type.

(1) Install the water drainage pipe.

Case for Model FXDQ ~ SPV1

Connecting interface of

the water drainage pipe

Refrigerant pipe

Water drainage port for maintenance

(With a rubber plug)

·

When installing the water drainage pipe, ensure that

the water drainage is smooth.

·

The diameter of the water drainage pipe shall be larger

than or equal to that of the connection pipe (polyethylene

pipe; pipe dimensions: 20 mm; outer diameter: 26 mm).

(Not including the riser pipe)

Содержание FXDQ-SPV1

Страница 1: ...FXDQ SPV1 EDTFVN391825 201803 Engineering Data 50 Hz...

Страница 2: ......

Страница 8: ...FXDQ SPV1 EDTFVN391825 6 3 Dimensions FXDQ20SPV1 FXDQ25SPV1 FXDQ32SPV1 3D071829D Unit mm...

Страница 9: ...FXDQ SPV1 EDTFVN391825 7 FXDQ40SPV1 FXDQ50SPV1 3D071831D Unit mm...

Страница 10: ...FXDQ SPV1 EDTFVN391825 8 FXDQ63SPV1 3D071830D Unit mm...

Страница 17: ...FXDQ SPV1 EDTFVN391825 15 9 Fan Performances FXDQ20SPV1 3D072697C...

Страница 18: ...FXDQ SPV1 EDTFVN391825 16 FXDQ25SPV1 3D072698C...

Страница 19: ...FXDQ SPV1 EDTFVN391825 17 FXDQ32SPV1 3D090527...

Страница 20: ...FXDQ SPV1 EDTFVN391825 18 FXDQ40SPV1 FXDQ50SPV1 3D072702C...

Страница 21: ...FXDQ SPV1 EDTFVN391825 19 FXDQ63SPV1 3D090542...

Страница 22: ...FXDQ SPV1 EDTFVN391825 20 10 Sound Levels FXDQ20SPV1 FXDQ25SPV1 4D090507A 4D090508A...

Страница 23: ...FXDQ SPV1 EDTFVN391825 21 FXDQ32SPV1 FXDQ40SPV1 FXDQ50SPV1 4D090509A 4D090510A...

Страница 24: ...FXDQ SPV1 EDTFVN391825 22 FXDQ63SPV1 4D090511A...

Страница 26: ...FXDQ SPV1 EDTFVN391825 24 FXDQ63SPV1 4D072720H Unit mm...

Страница 41: ......

Страница 42: ......

Страница 43: ......