Installation and operation manual

23

EWAQ016~ EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

5.5.

Service and maintenance

In order to ensure optimal operation of the unit, a number of checks

and inspections on the unit and the field wiring have to be carried out

at regular intervals.

This maintenance should be carried out by your local installer.

To execute maintenance first remove the panels as shown in

"4.2.2. Opening the unit" on page 7.

5.5.1.

Maintenance activities

Checks

The described checks must be executed at least

once a year

by

qualified personnel.

1

Pressure relief valve hose (if present)

Check that the pressure relief valve hose is positioned

appropriately to drain the water.

2

Water pressure relief valve

Check for correct operation of the pressure relief valve by

turning the red knob on the valve counter-clockwise:

■

If you do not hear a clacking sound, contact your local dealer.

■

In case the water keeps running out of the unit, close both

the water inlet and outlet shut-off valves first and then contact

your local dealer.

3

Switch box

Carry out a thorough visual inspection of the switch box and look

for obvious defects such as loose connections or defective

wiring.

4

Water pressure

Check if the water pressure is above 1 bar.

If necessary add water.

5

Water filter

Clean the water filter.

6

In case of use of glycol

(Refer to Caution: "Use of glycol" on page 11)

Document the glycol concentration and the pH-value in the

system at least once a year.

■

A pH-value below 8.0 indicates that a significant portion of

the inhibitor has been depleted and that more inhibitor needs

to be added.

■

When the pH-value is below 7.0 then oxidation of the glycol

occurred, the system should be drained and flushed

thoroughly before severe damage occurs.

Make sure that the disposal of the glycol solution is done in

accordance with the applicable legislation.

5.5.2.

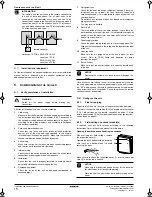

Error codes

5.5.3.

Important information regarding the refrigerant

used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type:

R410A

GWP

(1)

value:

1975

(1)

GWP = global warming potential

DANGER: ELECTRICAL SHOCK

See "2. Precautions for installation" on page 3.

WARNING: ELECTRIC SHOCK

■

Before carrying out any maintenance or repair activity,

always switch off the circuit breaker on the supply

panel, remove the fuses or open the protection

devices of the unit.

■

Do not touch live parts for 10 minutes after the power

supply is turned off because of high voltage risk.

■

Please note that some sections of the electric

component box are hot.

■

Make sure you do not touch a conductive section.

■

Do not rinse the unit. This may cause electric shocks

or fire.

Play it safe!

Touch a metal part by hand (such as the stop valve) in

order to eliminate static electricity and to protect the PCB

before performing service.

Error code

Failure cause

Corrective action

A1

Failure of writing memory

(EEPROM error)

Contact your local dealer.

A6

Malfunction water circuit

• Make sure waterflow is

possible (open all valves in

the circuit).

• Force clean water through

the unit.

A9

R410A expansion valve error

(K11E/K21E)

• Check wiring connections.

• Contact your local dealer.

AE

Water system warning

• Check filter.

• Make sure all valves are

open.

• Contact your local dealer.

AJ

Capacity error

Contact your local dealer.

C1

Bad ACS communication

Contact your local dealer.

C4

R410A liquid thermistor error

(R13T/R23T)

• Check wiring connections.

• Contact your local dealer.

C9

Returning water thermistor

error (R12T/R22T)

• Check wiring connections.

• Contact your local dealer.

CA

Heating leaving water

thermistor error (R11T/R12T)

• Check wiring connections.

• Contact your local dealer.

CJ

Remote controller thermostat

thermistor error

Contact your local dealer.

E3

High pressure error

(SENPH/S1PH)

• Make sure the circuit is

filled with water (no air

inside, e.g. is the air purge

open?)

• Make sure water flow is

possible (open all valves in

the circuit).

• Make sure the water filter is

not blocked.

• Make sure all refrigerant

stop valves are open.

• Contact your local dealer.

E4

Low pressure error (SENPL)

Contact your local dealer.

J7

R410A suction thermistor

error (R14T/R24T)

• Check wiring connections.

• Contact your local dealer.

U1

The phases of the power to

the unit is reversed.

Exchange two of the three

phases (L1, L2, L3) to make a

positive phase connection.

U2

Power supply error

• Check wiring connections.

• Contact your local dealer.

UA

Type connection problem

• Wait till initialisation

between outdoor module

and hydro module finished

(after power ON, wait at

least 12 minutes).

• Contact your local dealer.

UH

Address error

Contact your local dealer.

4PWEN70082-1C.book Page 23 Wednesday, September 25, 2013 7:31 AM

Содержание EWAQ016BAW

Страница 47: ......

Страница 48: ...4PW70082 1C 2013 07 Copyright 2011 Daikin...