Installation and operation manual

41

EWAQ016~ EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

7.

M

AINTENANCE

7.1.

Important information regarding the refrigerant

used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol.

Refrigerant type: R410A

GWP

(1)

value: 1975

(1)

GWP = global warming potential

Periodical inspections for refrigerant leaks may be required

depending on the applicable legislation. Please contact your local

dealer for more information.

7.2.

Maintenance activities

In order to ensure optimal availability of the unit, a number of checks

and inspections on the unit and the field wiring have to be carried out

at regular intervals, preferably yearly. This maintenance should be

carried out by your local Daikin technician (see installation manual).

The only maintenance which may be required by the operator is:

■

keeping the remote controller clean by means of a soft damp

cloth,

■

checking if the water pressure indicated on the manometer is

above 1 bar.

7.3.

Standstill

8.

T

ROUBLESHOOTING

The guidelines below might help to solve your problem. If you cannot

solve the problem, consult your installer.

8.1.

Error codes

9.

D

ISPOSAL

REQUIREMENTS

Dismantling of the unit, treatment of the refrigerant, of oil and of other

parts must be done in accordance with the applicable legislation.

Do not try to dismantle the system yourself: the dismantling of the

system, treatment of the refrigerant, of oil and other parts must be

done by a qualified installer in accordance with the applicable

legislation.

Units must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed off

correctly, you will help to prevent potential negative consequences for

the environment and human health. Please contact the installer or

local authority for more information.

CAUTION

If the supply cord is damaged, it must be replaced by the

manufacturer, its agent or similar qualified persons in order

to avoid hazards.

NOTICE

During longer periods of standstill, e.g. during winter with a

cooling only application and option heater tape installed

(refer to "3.1. Check that you have all optional equipment"

on page 3) DO NOT switch off the power supply to the unit.

Otherwise power supply to the heater tape is cut off and

the piping will freeze.

See "4.5.5. Protecting the water circuit against freezing"

on page 11 if you want to cut off power supply during

winter stand still.

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTIONS

No readings on the remote controller

(blank display)

• Check if the mains power is still

connected to your installation.

• The benefit kWh rate power

supply is active (see installation

manual).

One of the error codes appears

Consult your local dealer.

Refer to the installation manual for a

detailed list of error codes.

The schedule timer does work but

the programmed actions are

executed at the wrong time.

(e.g. 1 hour too late or too early)

Check if the clock and the day of the

week are set correctly, correct if

necessary.

The schedule timer is programmed

but does not work.

In case the

icon is not displayed,

push the

button to enable the

schedule timer.

Capacity shortage

Consult your local dealer.

Temperature values displayed on the

remote controller (remote controller)

are displayed in °F instead of °C.

To change the display back to °C,

push

and

buttons

simultaneously for 5 seconds.

Execute same procedure to change

back to the °F display. The default

temperature display is in °C.

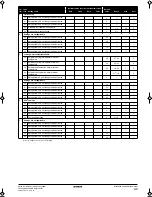

Error code

Failure cause

Corrective action

A1

Failure of writing memory

(EEPROM error)

Contact your local dealer.

A6

Malfunction water circuit

• Make sure waterflow is

possible (open all valves in

the circuit).

• Force clean water through

the unit.

A9

R410A expansion valve error

(K11E/K21E)

• Check wiring connections.

• Contact your local dealer.

AE

Water system warning

• Check filter.

• Make sure all valves are

open.

• Contact your local dealer.

AJ

Capacity error

Contact your local dealer.

C1

Bad ACS communication

Contact your local dealer.

C4

R410A liquid thermistor error

(R13T/R23T)

• Check wiring connections.

• Contact your local dealer.

C9

Returning water thermistor

error (R12T/R22T)

• Check wiring connections.

• Contact your local dealer.

CA

Heating leaving water

thermistor error (R11T/R12T)

• Check wiring connections.

• Contact your local dealer.

CJ

Remote controller thermostat

thermistor error

Contact your local dealer.

E3

High pressure error

(SENPH/S1PH)

• Make sure the circuit is

filled with water (no air

inside, e.g. is the air purge

open?)

• Make sure water flow is

possible (open all valves in

the circuit).

• Make sure the water filter is

not blocked.

• Make sure all refrigerant

stop valves are open.

• Contact your local dealer.

E4

Low pressure error (SENPL)

Contact your local dealer.

J7

R410A suction thermistor

error (R14T/R24T)

• Check wiring connections.

• Contact your local dealer.

U1

The phases of the power to

the unit is reversed.

Exchange two of the three

phases (L1, L2, L3) to make a

positive phase connection.

U2

Power supply error

• Check wiring connections.

• Contact your local dealer.

UA

Type connection problem

• Wait till initialisation

between outdoor module

and hydro module finished

(after power ON, wait at

least 12 minutes).

• Contact your local dealer.

UH

Address error

Contact your local dealer.

4PWEN70082-1C.book Page 41 Wednesday, September 25, 2013 7:31 AM

Содержание EWAQ016BAW

Страница 47: ......

Страница 48: ...4PW70082 1C 2013 07 Copyright 2011 Daikin...