Installation and operation manual

19

EWAQ016~ EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

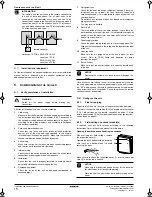

Operation example

: Schedule timer based on ON/OFF instruction.

When setback function (refer to "[2] Automatic setback function" on

page 19) is enabled, the setback operation will have priority over the

scheduled action in the schedule timer if ON instruction is active. If

OFF instruction is active this will have priority over the setback

function. At any time the OFF instruction will have the highest priority.

■

[0-04]

Status: defines whether the ON/OFF instruction can be

used in the schedule timer for cooling.

Same as for [0-03] but for cooling schedule timer.

For cooling, no setback function is available.

[1] Settings are not applicable

[2] Automatic setback function

Setback function provides the possibility to lower the room

temperature. The setback function can for instance be activated

during the night because the temperature demands during night and

day are not the same.

■

[2-00]

Status: defines whether the setback function is turned ON

(1) or OFF (0)

■

[2-01]

Start time: time at which setback is started

■

[2-02]

Stop time: time at which setback is stopped

Setback can be configured for both room temperature control and

leaving water temperature control.

Refer to "[5] Automatic setback" on page 20 for temperature set

points.

Method 2

Space heating based on ON/OFF instruction

During operation

When the schedule timer switches space heating OFF,

the controller will be switched off (operation LED will stop

working).

When pushing

the

button

The schedule timer for space heating will stop (when

active at that moment) and will start again at the next

scheduled ON function.

The "last" programmed command overrules the

"preceding" programmed command and will remain

active until the "next" programmed command occurs.

Example: imagine the actual time is 17:30 and

actions are programmed at 13:00, 16:00 and 19:00.

The "last" programmed command (16:00) overruled

the "previous" programmed command (13:00) and

will remain active until the "next" programmed

command (19:00) occurs.

So in order to know the actual setting, one should consult

the last programmed command. It is clear that the "last"

programmed command may date from the day before.

Refer to the operation manual.

The controller will be switched off (operation LED will

stop working).

However the schedule timer icon will stay displayed.

When pushing

the

button

The schedule timer for space heating along with the quiet

mode will be stopped and will not start again.

The schedule timer icon will not be displayed anymore.

1

Schedule timer

2

Setback function

3

When both setback function and schedule timer are enabled

A

Setback function

B

ON/OFF instruction

t

Time

T

Temperature set point

Room temperature

Leaving water temperature

t

18

18

°

C

40

40

°

C

40

°

C

18

°

C

A

5:00

5:00

23:00

23:00

5:00

23:00

2

B

t

9:00

16:00

19

19

°

C

19

19

°

C

22

22

°

C

21

21

°

C

42

42

°

C

42

42

°

C

45

45

°

C

44

44

°

C

19

°

C

19

°

C

22

°

C

21

°

C

42

°

C

42

°

C

45

°

C

44

°

C

1

OFF

ON

ON

6:30

0:30

B

t

6:30

9:00

16:00

23:00

19

19

°

C

19

19

°

C

22

22

°

C

21

21

°

C

42

42

°

C

42

42

°

C

45

45

°

C

44

44

°

C

19

°

C

19

°

C

22

°

C

21

°

C

42

°

C

42

°

C

45

°

C

44

°

C

3

OFF

ON

ON

18

18

°

C

40

40

°

C

40

°

C

18

°

C

INFORMATION

Only for EWYQ units operating in heating mode.

Setback function for cooling does not exist.

INFORMATION

■

By default the setback function is enabled.

■

The setback function can be combined with the

automatic weather dependent set point operation.

■

Setback function is an automatic daily scheduled

function.

A

Normal room temperature set point

B

Room setback temperature [5-03]

t

Time

T

Temperature

A

Normal leaving water temperature set point

B

Leaving water setback temperature [5-02]

t

Time

T

Temperature

[2-01]

[2-02]

A

B

T

t

21

°

C

18

°

C

[2-01]

[2-02]

B

A

T

t

45

°

C

40

°

C

5

°

C [5-02]

4PWEN70082-1C.book Page 19 Wednesday, September 25, 2013 7:31 AM

Содержание EWAQ016BAW

Страница 47: ......

Страница 48: ...4PW70082 1C 2013 07 Copyright 2011 Daikin...