Installation and operation manual

13

EWAQ016~ EWYQ016~064BAW

Packaged air-cooled water chiller

4PW70082-1C – 2013.07

4.6.2.

Internal wiring – Parts table – Hydro module

Refer to the wiring diagram sticker on the hydro module front panel 1

(refer to "4.2.2. Opening the unit" on page 7). The abbreviations used

are listed below:

A1P ........................Main PCB (master)

A2P ........................remote controller PCB

A3P ........................Control PCB

A4P ........................Demand PCB (optional)

A5P ........................Main PCB (slave)

A6P ........................Demand PCB (optional)

A7P ........................Remote controller PCB (optional)

C1~C3 ....................Filter capacitor

E1H ........................Switch box heater

E2H ........................Plate heat exchanger heater (PHE1)

E3H ........................Plate heat exchanger heater (PHE2)

E4H ........................Water piping heater

E5H ........................Expansion vessel heater

F1,F2......................Fuse (F, 5 A, 250 V)

F1U (A*P)...............Fuse (T, 3.15 A, 250 V)

HAP........................PCB LED

K11E ......................Electronic expansion valve (PHE1)

K21E ......................Electronic expansion valve (PHE2)

K1P ........................Pump contactor

K1S ........................Pump overcurrent relay

K*R (A3P)...............PCB relay

M1P........................Pump

PS (A*P).................Switching power supply

Q1DI.......................Earth leakage circuit breaker (field supply)

Q1T ........................Thermostat for expansion vessel heater

R11T ......................Leaving water thermistor (PHE1)

R12T ......................Returning water thermistor (PHE1)

R13T ......................Refrigerant liquid thermistor (PHE1)

R14T ......................Refrigerant gas thermistor (PHE1)

R21T ......................Leaving water thermistor (PHE2)

R22T ......................Returning water thermistor (PHE2)

R23T ......................Refrigerant liquid thermistor (PHE2)

R24T ......................Refrigerant gas thermistor (PHE2)

S1F.........................Flow switch (PHE1)

S2F.........................Flow switch (PHE2)

S1M........................Main switch

S1S ........................Thermostat ON/OFF input (field supply)

S2S ........................Thermostat cooling/heating selection

(field supply)

S3S ........................Operation ON input (field supply)

S4S ........................Operation OFF input (field supply)

SS1 (A1P,A5P) .......Selector switch (emergency)

SS1 (A2P) ..............Selector switch (master/slave)

SS1 (A7P) ..............Selector switch (master/slave) (optional)

V1C,V2C ................Ferrite core noise filter

X1M~X4M ..............Terminal strip

X801M (A*P) ..........PCB terminal strip (optional)

Z1F,Z2F (A*P) ........Noise filter

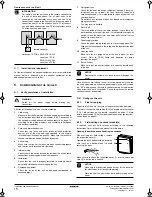

4.6.3.

Installing the main switch handle

Open panel 1 (refer to "4.2.2. Opening the unit" on page 7) and

mount the main switch handle parts as shown below. The handle of

the main switch is mounted on panel 1.

■

For EWA/YQ016~032 refer to figure 10.

A

Panel 1 (refer to "4.2.2. Opening the unit" on page 7)

■

For EWA/YQ040~064 refer to figure 14.

A

Panel 1 (refer to "4.2.2. Opening the unit" on page 7)

4.6.4.

System overview of field wiring

Field wiring consists out of power supply (always including earth) and

communication (=transmission) wiring.

■

Most field wiring on the unit is to be made on the terminal blocks

inside the switch boxes. To gain access to the terminal blocks,

remove switch box service panel. Refer to the instructions

described in "4.2.2. Opening the unit" on page 7 how to remove

this panel and gain access to the inside of the switch box.

■

Cable tie mountings are provided at the wiring entries of the

switch box. See "4.4.2. Main components of the hydro module"

on page 8.

4.6.5.

Connection of the unit power supply and

communication cable(s)

The power supply must be protected with the required safety devices,

i.e. a main switch, a slow blow fuse on each phase and an earth

leakage protector in accordance with the applicable legislation.

Cable requirements

NOTICE

When the main switch is in OFF position, it is possible

to lock the main switch using a suitable padlock.

Refer to figure 13.

Keep in mind that in this case the padlock needs to be

opened and removed before it is possible to turn the

main switch to the ON position.

INFORMATION

■

The electrical wiring diagram can be found on the

inside of the switch box cover.

■

Install the unit, power supply cable and

communication cables at least 1 meter away from

televisions or radios to prevent image interference or

noise.

(Depending on the radio waves, a distance of 1 meter

may not be sufficient to eliminate the noise.)

NOTICE

Selection and sizing of the wiring should be done in

accordance with the applicable legislation based on the

information mentioned in the table below:

Item

Cable

bundle Description

Required

number of

conductors

Maximum

running

current

1

PS

Power supply

4+GND

(b)

(b) Refer to the nameplate on the unit or to the technical data book.

2

LV

Standard remote controller (F1/F2)

2

(c)

(c) Minimum cable section 0.75 mm

2

.

3

LV

Secondary remote controller

(P1/P2)

(a)

(a) Optional

2

(c)

4

LV

Thermostat ON/OFF signal

(a)

2

(c)

5

LV

Thermostat cooling/heating signal

(a)

2

(c)

6

LV

Operation ON signal

(a)

2

(c)

7

LV

Operation OFF signal

(a)

2

(c)

8

HV

Cooling/heating output

2

0.3 A

9

HV

Operation ON/OFF output

2

0.3 A

10

HV

Error output

2

0.3 A

11

HV

Water piping heater output

2

1 A

12

HV

Pump ON/OFF output

2

0.3 A

(d)

(d) Only for models without pump (EWAQ*BAW(P/H)* and EWYQ*BAW(P/H)* units.)

.

PS = Power supply (see "4.6.6. Routing" on page 14)

LV = Low voltage (see "4.6.6. Routing" on page 14)

HV = High voltage (see "4.6.6. Routing" on page 14)

4PWEN70082-1C.book Page 13 Wednesday, September 25, 2013 7:31 AM

Содержание EWAQ016BAW

Страница 47: ......

Страница 48: ...4PW70082 1C 2013 07 Copyright 2011 Daikin...