27

1. Remove the drain trap and factory installed drain tube

assemblies.

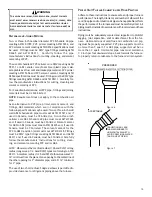

2. Remove two 1’’ plugs from right side of cabinet.

3. (Draining the Collector Box) From outside the cabinet,

insert the non-grommet end hose #7 into the back

drain hole and secure to collector box drain port using a

silver clamp.

4. (Draining the Vent Elbow) Insert the straight barbed

coupling into the vent - drain elbow drip leg and secure

with a red clamp.

5. From outside the cabinet, insert te non-grommet end of

hose #8 into the front cabinet drain hole and secure on

the vent - drain elbow barb fitting using a red clamp.

6. Place the drain hoses on the trap inlets and secure

with silver clamps. The outlet of the trap must face

the original botom of furnace.

7. Using the two sheet metal screws provided in the

cabinet, secure the trap to the furnace.

8. Refer to Field Supplied Drain section for instructions

on field supplied/installed drain on outlet of furnace

trap.

C

OUNTERFLOW

M

ODEL

I

NSTALLED

H

ORIZONTALLY

WITH

L

EFT

S

IDE

D

OWN

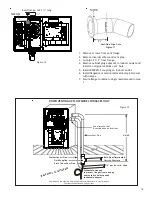

Minimum 5 1/2" clearance is required for the drain trap

beneath the furnace.

*Also see Front Cover Pressure Switch Tube Location

on page 14.

Hose #4

Hose #5

Hose #4

Hose #2

Figure 30

1. Remove the factory installed drain trap and hose

assemblies. Leave the 100°elbow inserted and

clamped in the vent drain elbow.

2. Remove two 1”plugs from left side of cabinet

3. (Draining the Collector Box) Remove the cap from the

left side of the collector box drain port (bottom in

horizontal left position) and install it on right side drain

port.

4. Place radius end of hose #4 (factory installed) on the

collector box drain port and secure with a silver clamp.

5. Insert hose #2 from outside the cabinet in the front

drain hole.

6. Connect hose #4 & hose #2 together using a straight

barbed coupling and two gold clamps (factory installed).

7. (Draining the Vent Elbow) Remove rubber plug from

vent – drain elbow side port.

8.

The unused vent-drain elbow drip leg port must be

plugged to prevent flue gases from escaping.

Insert

rubber plug removed in step 7 into the 100° elbow..

(Inserting a blunt tool such as a 3/16’’ Allen wrench

into the center of the rubber plug will stretch the plug

and allow complete insertion)

9. Place radius end of hose #4 on the side port of vent –

drain elbow and secure with a gold clamp.

10. Insert a ½” diameter PVC pipe (factory installed) into

hose #4 and secure with a gold clamp.

11. Insert the non-grommet end of hose #5 (factory

installed) from outside the cabinet in the back drain

hole.

12. Insert 100º elbow in hose #5 and secure with a red

clamp.

13. Locate hose #4 and cut a cut off a 4” straight section

and discard the radius end.

14. Connect the 4” straight section of hose #4 to the

100º elbow and the PVC pipe and secure with red

clamps.

15. Connect the hoses to the trap inlets and secure

with silver clamps, drain trap outlet must point to

the original bottom of the furnace.

16. Using the two sheet metal screws provided in the

cabinet, secure the trap to the furnace.

17. Refer to Field Supplied Drain section for instructions

on field supplied / installed drain on outlet of

furnace trap.

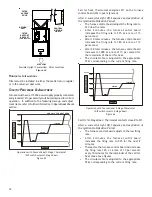

E

LECTRICAL

C

ONNECTIONS

HIGH VOLTAGE !

T

O

AVOID

THE

RISK

OF

ELECTRICAL

SHOCK

,

WIRING

TO

THE

UNIT

MUST

BE

POLARIZED

AND

GROUNDED

.

WARNING

HIGH VOLTAGE !

T

O

AVOID

PERSONAL

INJURY

OR

DEATH

DUE

TO

ELECTRICAL

SHOCK

,

DISCONNECT

ELECTRICAL

POWER

BEFORE

SERVICING

OR

CHANGING

ANY

ELECTRICAL

WIRING

.

WARNING

Содержание DC97MC

Страница 63: ...63 THIS PAGE LEFT INTENTIONALLY BLANK...