32

G

AS

P

IPING

C

ONNECTIONS

T

O

AVOID

POSSIBLE

UNSATISFACTORY

OPERATION

OF

EQUIPMENT

DAMAGE

DUE

TO

UNDERFIRING

OR

EQUIPMENT

,

USE

THE

PROPER

SIZE

OF

NATURAL

/

PROPANE

GAS

PIPING

NEEDED

WHEN

RUNNING

PIPE

FROM

THE

METER

/

TANK

TO

THE

FURNACE

.

WARNING

The gas piping supplying the furnace must be properly sized

based on the gas flow required, specific gravity of the gas,

and length of the run. The gas line installation must comply

with local codes, or in their absence, with the latest edition

of the National Fuel Gas Code, NFPA 54/ANSI Z223.1 or CAN/

CSA B149.1-15 in Canada.

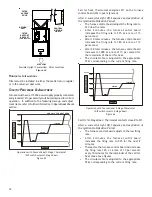

Natural Gas Capacity of Pipe In Cubic Feet of Gas Per Hour (CFH)

Nominal

½

¾

1

1¼

1½

2

2½

Actual ID:

0.622

0.824

1.049

1.380

1.610

2.067

2.469

Length (ft)

10

170

360

678

1390

2090

4020

6400

20

118

247

466

957

1430

2760

4400

30

95

199

374

768

1150

2220

3530

40

81

170

320

657

985

1900

3020

50

72

151

284

583

873

1680

2680

60

65

137

257

528

791

1520

2430

70

60

126

237

486

728

1400

2230

80

56

117

220

452

677

1300

2080

90

52

110

207

424

635

1220

1950

100

50

104

195

400

600

1160

1840

125

44

92

173

355

532

1020

1630

150

40

83

157

322

482

928

1480

175

37

77

144

296

443

854

1360

200

34

71

134

275

412

794

1270

250

30

63

119

244

366

704

1120

Capacity in Cubic Feet of Gas per Hour

This chart refers to natural gas w ith an inlet pressure of less than 2 psi and a

pressure drop of 0.5" W.C. Specific gravity is 0.60.

Pipe Size (in.)

CFH =

BTUH Furnace Input

Heating Valve of Gas (BTU/Cubic Foot)

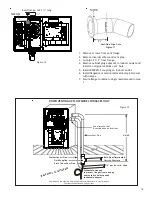

To connect the furnace to the building’s gas piping, the in-

staller must supply a ground joint union, drip leg, manual

shutoff valve, and line and fittings to connect to gas valve. In

some cases, the installer may also need to supply a transition

piece from 1/2" pipe to a larger pipe size.

The following stipulations apply when connecting gas piping.

Refer to

Gas Piping Connections

figure for typical gas line

connections to the furnace.

•

Gas piping must be supported external to the furnace

cabinet so that the weight of the gas line does not

distort the burner rack, manifold or gas valve.

•

Use black iron or steel pipe and fittings for building

piping. Where possible, use new pipe that is properly

chamfered, reamed, and free of burrs and chips. If old

pipe is used, be sure it is clean and free of rust, scale,

burrs, chips, and old pipe joint compound.

•

Use pipe joint compound on male threads ONLY. Always

use pipe joint compound (pipe dope) that is APPROVED

FOR ALL GASES. DO NOT apply compound to the first

two threads.

•

Use ground joint unions.

•

Install a drip leg to trap dirt and moisture before it can

enter the gas valve. The drip leg must be a minimum

of three inches long.

•

A line pressure test port is provided on the gas

valve. If desired, install a 1/8" NPT pipe plug fitting,

accessible for test gage connection, immediately

upstream of the gas supply connection to the furnace.

•

Always use a back-up wrench when making the

connection to the gas valve to keep it from turning.

The orientation of the gas valve on the manifold must

be maintained as shipped from the factory. Maximum

torque for the gas valve connection is 375 in-lbs;

excessive over-tightening may damage the gas valve.

•

Install a manual shutoff valve between the gas meter

and unit within six feet of the unit. If a union is installed,

the union must be downstream of the manual shutoff

valve, between the shutoff valve and the furnace.

•

Tighten all joints securely.

•

Connection method must be in compliance with all

local and national codes. US: National Fuel Gas Code

(NFGC) NFPA 54-2012/ANSI Z223.1-2012 and the

Installation Standards, Warm Air Heating and Air

Conditioning Systems ANSI/NFPA 90B.

In Canada, CANADA: National Standard of Canada,

Natural Gas and Propane Installation Code

(NSCNGPIC) CSA B149.1-15.

Connect the furnace to the building piping by one of the

following methods:

–

Rigid metallic pipe and fittings.

–

Semi-rigid metallic tubing and metallic fittings.

Aluminum alloy tubing must not be used in exterior

locations. In order to seal the grommet cabinet

penetration, rigid pipe must be used to reach the

outside of the cabinet. A semi-rigid connector to

the gas piping may be used from there.

•

Use listed gas appliance connectors in accordance with

their instructions. Connectors must be fully in the same

room as the furnace.

•

Protect connectors and semirigid tubing against physical

and thermal damage when installed. Ensure aluminum-

alloy tubing and connectors are coated to protect

against external corrosion when in contact with masonry,

plaster, or insulation, or subjected to repeated wetting

by liquids such as water (except rain water), detergents,

or sewage.

Содержание DC97MC

Страница 63: ...63 THIS PAGE LEFT INTENTIONALLY BLANK...