36

12.

TEST METHOD AND OPERATION CHECK (FOR IACS M10.13)

To check the HIGH ALARM and PRE ALARM functions or to check operation of sensors, refer to Section [11

OPERATION].

Sensors are calibrated before delivery from our plant. So the scales will not be changed.

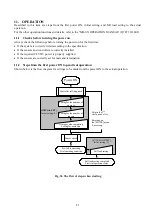

At starting and stopping the engine during daily operation, check whether the mist levels indicated by the

controller are increased. By this check, you can judge whether the sensors are operating properly.

When the engine can not be operated, the working condition of the sensor can be confirmed by the density

difference between lubrication oil priming pump works and stops.

It can be checked the change of the mist level on the controller LCD when the engine working and stopped in

daily operation check. If the mist level of engine working is increased more than that of engine stop, the oil

mist detector can be judged normal.

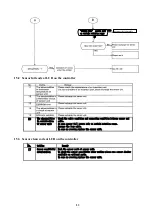

However, if you have to check a sensor only without operating the engine, remove the sensor, correctly connect

the cable, and then turn on the power of the controller.

After that, using the spray type smoke tester, directly spray the smoke to the removed sensor. Check whether the

sensor can correctly detect the smoke.

In that work, sensor can be reacted earlier by reducing smoke leaving from sensor inside when all holes of

sensor hood, except for the hole smoke is inserted are blocked by hand like photo34.

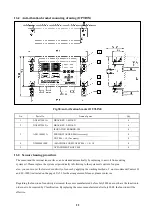

Fig.37

Spray test

Original content from www.daihatsu.cc

Issued to HORIZON TANKERS LIMITED S.A.