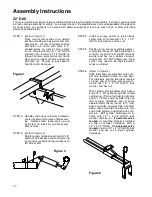

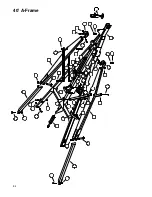

Wobble Slot Seed Cup Adjustments and Service

The wobble slot seed cups should be checked against

the slot gauge initially and anytime service has been

performed on the seed shaft or individual seed cups.

Refer to the drawing below for proper adjustment if

repairs have been made.

To verify that all seed cups are set the same on the

shaft, start with all cups fully closed. A slight crack

between the cup halves would be considered normal

tolerance. If any individual cup is not "zeroed out," open

the slot width using the adjusting handle, loosen allen set

screws and adjust to equal others on shaft.

To determine if the gauge is reflecting the correct seed

cup slot width, open the seed cups using the adjusting

handle. Notice that wobble slot halves are positioned

differently on the hex shaft. Identify a cup that will accept

a piece of ½" keystock or other measuring device com

fortably and give solid contact against each half. It may

be necessary to turn the hex shaft slightly to position the

particular seed cup correctly. Close the slot width firmly

against the measuring device. At the cup next to the

wobble slot adjusting handle, position the gauge to

equal the slot width you have just measured with the

keystock by loosening with a screwdriver and sliding in

or out.

Small changes in rate can be made by opening or

closing slot width. To close the slot width with grain in

the box, close the slot down a maximum of 1/8" and

then rotate the shaft one turn to clear the slot. Repeat

this process until the desired slot width is selected.

Seeding rate is affected by seed size, seed

treatments, foreign material, and test weight. Refer

to seed rate charts as guidelines for desired

seeding rates.

Chain Tension on Drive Shaft

When making sprocket changes to the seed shaft,

tighten chain to leave approximately ½" of flex. The

final sprocket must allow the hex shaft to slide within

the sprocket when the adjusting lever is moved. If

the chain is too tight, bowing and binding of box end

will occur making seed cup adjustment difficult.

Lightly lubricate the shaft where the sprocket will

slide.

DO NOT OVERTIGHTEN CHAIN.

21

Содержание 3200

Страница 1: ...3200 Trash Shank OWNER S MANUAL 01 10 601401 ...

Страница 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Страница 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Страница 7: ...Safety HANDLE FUEL SAFELY AVOID FIRES PREPARE FOR EMERGENCIES WEAR PROTECTIVE CLOTHING 5 ...

Страница 8: ...Safety USE SAFETY LIGHTS AND DEVICES TRANSPORT SAFELY 6 ...

Страница 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Страница 10: ...Safety AVOID HIGH PRESSURE FLUIDS CHARGE ROW MARKER HYDRAULIC SYSTEM 8 ...

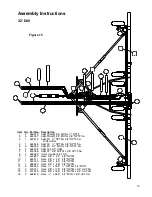

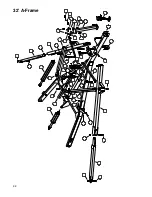

Страница 34: ...32 A Frame 32 ...

Страница 36: ...40 A Frame 34 ...

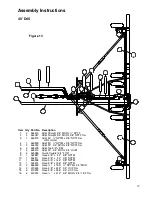

Страница 38: ...Center Frame Section 36 ...

Страница 40: ...32 Left Wing Section 38 ...

Страница 42: ...32 Right Wing Section 40 ...

Страница 44: ...40 Left Wing Section 42 ...

Страница 46: ...40 Right Wing Section 44 ...

Страница 48: ...Center Drive Assembly 46 ...

Страница 50: ...Left Drive Assembly 48 ...

Страница 52: ...Right Drive Assembly 50 ...

Страница 54: ...Box Assembly 52 ...