Maintenance

1. Preventative maintenance is the key to the

long life of any farm implement. With careful

and systematic inspection of your grain drill,

you can avoid costly maintenance time and

repairs.

2. Grease the following daily: all zerks, chain

idlers, wing frame hinge, wheel arm pivots,

rocker bearings, fold slide rods.

3. After using your implement for several hours,

check all bolts to be sure they are tight.

4. At the end of each season, clean the feed slot

with diesel fuel. This will provide a protective

coating against rust and corrosion. Be careful

when cleaning with diesel fuel so that it does

not ignite. Use only in a well ventilated area

and away from sparks or flames.

5. Clean and repack all wheel bearings at the

beginning of each season. Also, check during

the season and take up if necessary.

6. When the points of the hoe teeth wear down,

reverse the point and use the other end.

18

Содержание 3200

Страница 1: ...3200 Trash Shank OWNER S MANUAL 01 10 601401 ...

Страница 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Страница 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Страница 7: ...Safety HANDLE FUEL SAFELY AVOID FIRES PREPARE FOR EMERGENCIES WEAR PROTECTIVE CLOTHING 5 ...

Страница 8: ...Safety USE SAFETY LIGHTS AND DEVICES TRANSPORT SAFELY 6 ...

Страница 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Страница 10: ...Safety AVOID HIGH PRESSURE FLUIDS CHARGE ROW MARKER HYDRAULIC SYSTEM 8 ...

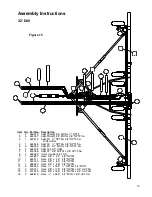

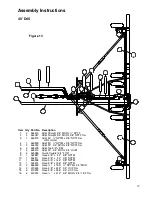

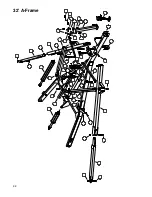

Страница 34: ...32 A Frame 32 ...

Страница 36: ...40 A Frame 34 ...

Страница 38: ...Center Frame Section 36 ...

Страница 40: ...32 Left Wing Section 38 ...

Страница 42: ...32 Right Wing Section 40 ...

Страница 44: ...40 Left Wing Section 42 ...

Страница 46: ...40 Right Wing Section 44 ...

Страница 48: ...Center Drive Assembly 46 ...

Страница 50: ...Left Drive Assembly 48 ...

Страница 52: ...Right Drive Assembly 50 ...

Страница 54: ...Box Assembly 52 ...