Assembly Instructions

32' Drill

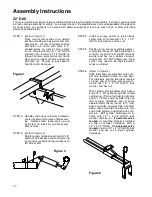

STEP 17 FOLD ADJUSTMENTS. Install cylinder

lockout in center frame cylinder and se-

cure with 5/16" x 2 3/4" pin. Switch selec-

tor valve to fold cylinder. Slowly fold drill

checking for clearances and binding.

Move wing carrier so stands contact wing

frames at a clear location. Tighten

3/4" x 6" HHCS to hold wing carrier. If

wings do not fold fully, adjust clevis screw

in end of fold arms. Screw in to fold fur-

ther, and out so wing does not fold in as

far.

Raise latches on wing carrier and secure

with 3/4" pins. Raise wing wheels and drill

is ready for transport.

40' Drill

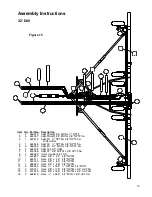

STEP 1

(Refer to Figure 1)

Place main center section in an upright

position standing on hoe points and suit-

able stands. Lift rear of A-frame to align

bolt holes in A-frame with holes in L-

shaped plates on front of main center

frame. Secure with four (4) 1" x 5" HHCS

and lock nuts. Install 1" x 2 1/2" HHCS up

through A-frame plate and center frame

plate on each side of A-frame and secure

with lock nut. Pin jack to jack spool to

hold front of A-frame up.

Figure 1

STEP 2

Spindles and hubs are factory installed in

center rockershaft to lessen field assem-

bly. Rotate center rockershaft up and

install four (4) 6 bolt rim and tire assem-

blies to hubs.

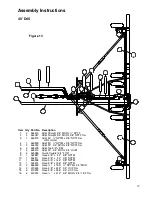

STEP 3

(Refer to Figure 3)

Rotate rockershaft down and install 4" x 8"

hydraulic cylinder base end to A-frame lug

(ram end to rockershaft lug) and ports to

left side of drill.

STEP 4

Install one hose carrier to tab on back

center stub of A-frame with 1/2" x 1 1/2"

HHCS, lock washer, and hex nut.

STEP 5

Position wing carrier assembly on A-frame

mounting plates. Secure with 5/8" x 2"

HHCS, lock washers, and hex nuts.

STEP 6

(Refer to Figure 6)

Place fold slide onto center of A-frame

with cylinder hole toward front. Bolt bot-

tom slide assembly on with eight (8) 1/2"

x 1 1/2" HHCS, flat washer, lock washers,

and hex nuts.

With cylinder pins provided, attach base

end of 3" x 40" hydraulic cylinder to fold

cylinder lug. (Ports of cylinder to right side

of drill.) Lift ram end of cylinder and slip

fold cylinder hold-down over A-frame

approximately twenty inches (20") from

base of cylinder. Lower cylinder into hold-

down, move fold slide to align with ram

end of fold cylinder, and attach with cylin-

der pin. Bolt cylinder hold-down to A-

frame with 1/2" x 5 1/2" HHCS, lock

washer, and hex nut.

If a selector valve

is used

, its mounting bracket is installed

on top of cylinder hold-down with a

1/2" x 5 1/2" HHCS.

If no selector valve

is used,

install a 1/2" x 4 1/2" HHCS, lock

washer, and hex nut in top of cylinder

hold-down.

Figure 6

Figure 3

14

Содержание 3200

Страница 1: ...3200 Trash Shank OWNER S MANUAL 01 10 601401 ...

Страница 5: ...Safety RECOGNIZE SAFETY INFORMATION UNDERSTAND SIGNAL WORDS FOLLOW SAFETY INSTRUCTIONS 3 ...

Страница 6: ...Safety OPERATE SAFELY AVOID TIP OVERS KEEP RIDERS OFF MACHINE 4 ...

Страница 7: ...Safety HANDLE FUEL SAFELY AVOID FIRES PREPARE FOR EMERGENCIES WEAR PROTECTIVE CLOTHING 5 ...

Страница 8: ...Safety USE SAFETY LIGHTS AND DEVICES TRANSPORT SAFELY 6 ...

Страница 9: ...Safety TOW LOADS SAFELY PRACTICE SAFE MAINTENANCE 7 ...

Страница 10: ...Safety AVOID HIGH PRESSURE FLUIDS CHARGE ROW MARKER HYDRAULIC SYSTEM 8 ...

Страница 34: ...32 A Frame 32 ...

Страница 36: ...40 A Frame 34 ...

Страница 38: ...Center Frame Section 36 ...

Страница 40: ...32 Left Wing Section 38 ...

Страница 42: ...32 Right Wing Section 40 ...

Страница 44: ...40 Left Wing Section 42 ...

Страница 46: ...40 Right Wing Section 44 ...

Страница 48: ...Center Drive Assembly 46 ...

Страница 50: ...Left Drive Assembly 48 ...

Страница 52: ...Right Drive Assembly 50 ...

Страница 54: ...Box Assembly 52 ...