UT

Handbook for Use and Maitenance – 50000 WB-80-87-95

Edition

01/11

Revisione

00

4

50000WB_e111_E.doc

(Chapter 1) - TECHNICAL FEATURES

1.1 - GENERAL

In order to work, the lorry crane must be installed on a vehicle and, from this vehicle,

take the mechanical power it needs. It follows that the correct performance and

safety of the system depend on the installation.

It is important to note that the capacities given on the plate that is located on the

crane are intended for lifting operations carried out with hook, pallets fork and

buckets for loose material or any other device that doesn’t build up other tensions on

the structure the those of the hook itself.

Lifting capacities are calculated for a crane servicing the vehicle on which it is

installed.

The use of the crane with the given lifting capacities is not permitted when the crane

is equipped with: buckets, hearth moving, magnets or any other equipment that can

cause to the crane stresses similar to those caused by the, here mentioned, devices.

Crane can not be used in explosive environment.

The crane is equipped with lifting eyes that make it possible to lift the crane by

respecting the gravity centre (picture 1). The crane shall be lifted with a proper lifting

beam equipped with chains and shakels in proportion with the crane weight.

The lifting points can bear the crane weight

only.

Picture 1

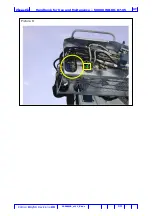

Picture 2