Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Combustion Research Corporation

Page 3

INSTALLATION NOTES

A. GENERAL INSTALLATION LAYOUT

1. Height from floor - 10' to 30' (refer to chart for

recommended minimum mounting heights). There are

no restrictions on the mounting height of the equipment

providing the design is based on the full heat loss of the

building. Consideration must be given to the building

heat loss so as to cover the air infiltration and/or the

mechanical ventilation of the building. For serviceability

and optimum performance the system should be

mounted with careful consideration to the use of the

building.

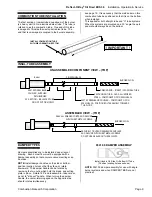

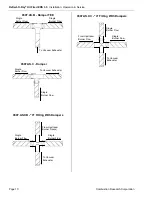

B. RADIANT TUBE ELEMENT LENGTHS FOR

STANDARD (OIL FIRED OIL FIRED EDS 3.5)

SYSTEMS.

1. To dissipate maximum heat and avoid continuous

condensation in the radiant tube elements, each burner

will be provided with the minimum or maximum tube

lengths as outlined in the following chart. A heavy walled

16 gauge aluminized steel tube (10' -0") long is used

adjacent or downstream of each burner. The remainder

of the radiant tubing shall be of spiral wound aluminized

steel tube. Each single flow of radiant tube shall

incorporate an adjustable damper for regulating burner

airflow.

2. A multiple burner system consists of two or more

burners. Refer to the following charts for radiant tube

lengths and elbow and tee placement.

C. RADIANT TUBE ELEMENT LENGTHS FOR HIGH

OUTPUT (OIL FIRED OIL FIRED EDS 3.5) SYSTEMS.

1. To dissipate maximum heat and avoid continuous

condensation in the radiant tube elements, each burner

will be provided with the minimum tube lengths as

outlined in the following chart. A heavy walled 16-gauge

aluminized steel tube 10' 0" long is used adjacent to

each burner. The remainder of the radiant tubing shall be

of spiral wound aluminized steel tube. Tee's must be

installed after any turbulator tube. Each single flow of

radiant tube shall incorporate an adjustable damper for

regulating burner airflow. NOTE: The radiant tubes for

the

Reflect-O-Ray

®

OIL FIRED EDS 3.5

systems can

and may be heat treated for optimum heat transfer.

DESIGN TUBE LENGTH REQUIREMENTS

FOR OPTIMUM EFFICIENCIES

The dimensions in the table listed below are basic

guidelines used in the design of the

Reflect-O-Ray

®

Oil Fired

OIL FIRED EDS 3.5

systems. Every effort should be made

to hold the dimensions given on the layout drawing. The

factory should verify any deviations from the layout drawing

or for alternate and/or customized layouts.

Burner Type

0500.R

125,000 Btu/hr

0510.R

105,000 BTU/HR

0520.R

70,000 Btu/hr

Standard Output System – Radiant Tube Between Any

Burner & Vacuum Exhauster

90’

70’

80’

60’

70’

50’

High Output (Reduced Tube Length) Systems

80’

60’

70’

40’

60’

40’

Maximum Flows Through One Radiant Tube

2

3

4

Minimum Distance Before Elbow

30’

25’

20’

Minimum Distance Before Tee

40’

40’

30’

Minimum Distance Before Damper

30’

30’

30’

* - Distances used with 0304.INSL radiant tube assemblies.

VACUUM EXHAUSTER SELECTION

Recommended Maximum Number of Burners Per Vacuum Exhauster

Note: The factory must be consulted for any deviations to the basic design criteria listed below. Burner inputs

may be mixed with each system (vacuum exhauster).

BURNER ASSEMBLIES

Vacuum Exhauster

0500.R

0510.R

0520.R

0402.WO/DI

4

4

6

0401.WO/DI

3

4

4

0201.WO

2

2

2

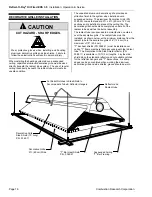

*40’

* 40’

Burner

Burner

40’

10’

40’ + 10’ + 40’ = 90’ From Vacuum Exhauster to either burner

* - In multiple burner systems the radiant

tubing runs do not have to be equal or

balanced in length.

Vacuum

Exhauster

Содержание reflect-o-ray eds 3.5

Страница 4: ......

Страница 57: ...Reflect O Ray Oil Fired EDS 3 5 Installation Operation Service Combustion Research Corporation Page 53 NOTES...

Страница 60: ......

Страница 61: ......