Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Page 14

Combustion Research Corporation

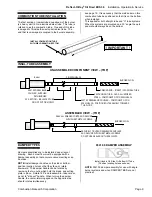

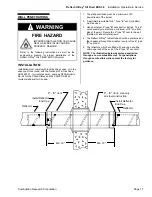

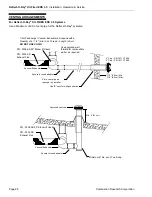

TUBE & REFLECTOR HANGING METHODS

The

Reflect-O-Ray

®

System reflectors can be suspended

horizontally or at a 30° angle. The combination hanger is

designed so that the reflector angle will be horizontal when

suspended from the top loop or at a 30° angle when

suspended from the offset loop – see the illustration below.

The panel hangers may also be suspended horizontally or at

a 30° angle – see illustration below.

Horizontal Mounting With

“Combination” Hanger

30° Mounting With

“Combination” Hanger

Horizontal Mounting With

“Panel” Hanger

30° Mounting With “Panel”

Hanger

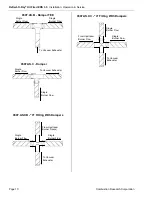

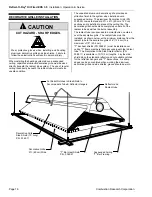

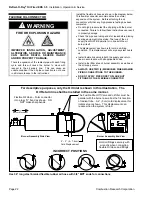

PERIMETER MOUNTING

In areas of high heat loss such as doorways and the

perimeter of some buildings, it may be desirable to

install the reflectors so that heat is concentrated and

directed to a specific area rather than straight down.

Two options are available to accomplish this, 1) angle

mount the reflector as shown above or 2) install side

shields.

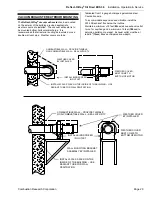

SIDE SHIELD INSTALLATION

Optional side shield reflectors may be installed on either

side or both sides of the reflector. The 10-ft. (3 m) long side

shields should line up with a reflector and have identical

overlap and expansion joints.

1. Position the side shield reflector next to the reflector, and

mark the areas where relief notches must be cut.

2. Cut the appropriate relief notches as noted.

3. Secure the side shield to the reflector with #8 x 3/8"

sheet metal screws. The screws should be used

approximately every 24" (61 cm).

4. Install the side shield supports every five feet (5’)

5. An expansion joint must be used in each straight run.

This expansion joint should match the location of the

expansion joint for the reflectors. All overlap areas

should also match the reflector overlap.

In applications where excessive air movement is

encountered, such as open doors and the like, the Side

Shields should be fastened together with 2 sheet metal

screws or pop rivets at each overlap joint.

NOTE:

DO NOT

screw the expansion joints together.

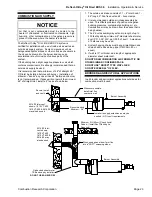

FIELD FAB

RELIEF NOTCH

IN SHIELD

SECURE WITH

S/M SCREW

SECURE SIDE

SHIELD HANGER

WITH S/M SCREW

SECURE SIDE

SHIELD SUPPORT

(P/N 0368.00) TO

TUBE WITH S/M

SCREW

0367.00

SIDE SHIELD

0360.00 REFLECTOR & 0367.00 SIDE SHIELD

FIELD FAB

RELIEF NOTCH

IN SHIELD

SECURE WITH S/M SCREW

SECURE

SIDE SHIELD

HANGER WITH

S/M SCREW

SECURE SIDE SHIELD

SUPPORT (P/N 0368.0010)

TO TUBE WITH S/M SCREW

0367.00

SIDE SHIELD

0812.00 REFLECTOR & 0367.00 SIDE SHIELD

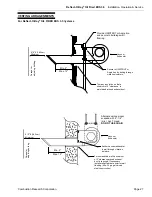

FIELD FAB

RELIEF NOTCH

SECURE WITH

S/M SCREW

SECURE

SIDE SHIELD

HANGER WITH

S/M SCREW

SECURE SIDE

SHIELD SUPPORT

(P/N 0366.0050)

TO TUBE WITH

S/M SCREW

0366.00

SIDE SHIELD

0363.00 REFLECTOR & 0366.00 SIDE SHIELD

Содержание reflect-o-ray eds 3.5

Страница 4: ......

Страница 57: ...Reflect O Ray Oil Fired EDS 3 5 Installation Operation Service Combustion Research Corporation Page 53 NOTES...

Страница 60: ......

Страница 61: ......