Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Page 36

Combustion Research Corporation

Notes

1. Before attempting to recycle unit after a nuisance shut

down: On flame failure or expiration of trial ignition,

electrical supply power to burner must be interrupted

for 5 minutes to allow safety switch to reset. Power can

be interrupted at burner service switch or at the

thermostat. Do not reset control more than 2 times as

accumulation of oil in the combustion chamber can and

will occur. Contact service personnel for assistance.

2. Do not attempt to field repair control components. It is

recommended defective components be replaced as

factory replacement units.

A. PRELIMINARY REQUIREMENTS PRIOR TO

STARTING SYSTEM

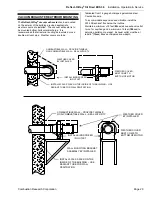

1. The system must be installed in compliance with

clearances to combustibles (see pages 4 - 6). Units

installed in public garages should be in accordance

with the ANSI/NFPA 88A-current standard for USA and

CAN 1-B149 .or .2 for Canada. Units installed in

aircraft hangars should be in accordance with

ANSI/NFPA 409-current standard for USA and

enforcing authority for Canada. All reflectors should be

in position and installed according to the installation

instructions and Start Up section tube system of this

manual.

2. Make sure all supply piping has been purged clean.

NOTE: Maximum oil supply to burner assemblies shall

not exceed 3 PSI.

3. The electrical system must be installed according to

local codes and the wire must be adequately sized for

the installation in accordance with the Electrical Wiring

Specification in the Installation Instructions and Start-

Up section of this manual. See that the fan is correctly

wired so the exhauster is running in the correct

direction and that none of the equipment is pulling

more than the specified capacities stated in the

Electrical Wiring section mentioned above.

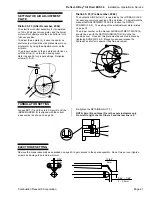

4. Adjustment of the damper on system is required so

that proper air flow for each burner is obtained.

B. TO START SYSTEM

1. Check to insure that oil supply system is in operation.

2. Check all burners to insure that fusible oil valves at

each burner are open.

3. Turn the main power switch to ON and check fuses.

4. Set the thermostat higher than the existing

temperature of the area to be heated. The following

steps should then take place automatically:

The vacuum exhauster is powered and will start. The

vacuum created by the exhauster pulls in the burner

air flow switch and supplies power to the ignition

control, opening the oil solenoid and generating spark

for ignition. The spark will ignite the oil.

5. Check all burners to see that they are operating.

Flame should be visible through the view window.

6. Set the thermostat down to the desired temperature.

7. When the system is initially fired, any oil that is on the

pipe work and fittings will burn off and form a light

haze in the building which can best be removed by

ventilation system in the building, or opening doors.

This is a one time problem and will not recur.

8. Burner tube may have a faint red glow in a darkened

room (950°F approx.).

9. On start-up there will be condensation in system for

approximately 2 minutes as fan discharge

temperature gets above the condensation point. The

condensation will be dried up in the pipe and

discharged through the fan. This results in a slight

spitting of this moisture out of the fan discharge for

approximately 4 minutes from initial start-up.

C. RESETTING THE FLAME SAFETY CONTROL

The

Reflect-O-Ray

®

Oil Fired EDS3.5

burner system is

equipped with an automatic lockout control which is

activated after 5 seconds if the burner should fail to ignite.

If your burner should lock out, it should be reset by the

follow method:

1. Make sure that the vacuum exhauster is operating.

The reset button on the back of the ignition control will

be lit (red LED lamp/button) signifying lockout.

2. Wait five minutes. Press the reset button and the

ignition sequence will start. Ignition should occur.

Do

not reset the burner more than two times.

3. The system will now automatically recycle on the

thermostat to maintain desired room temperature.

IF THE BURNER WILL NOT LIGHT AFTER TWO RESET

TRIALS, CONTACT YOUR INSTALLER FOR SERVICE.

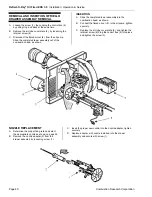

D. STOPPING THE SYSTEM FOR SERVICE

1. For servicing an individual burner or exhauster, turn

off the service toggle switch that should be mounted

within two feet of the unit. Close the oil supply valves

at the burner assembly.

2.

To service the thermostat, turn off the electrical power

at the main power disconnect box.

3.

Before servicing any fuel oil component; shut off the

oil supply and remove all electrical power.

CHECK SAFETY SHUTDOWN PERFORMANCE

NOTE:

Read steps 1-7 below before starting safety

shutdown or safety lockout tests for the direct ignition (DI)

module.

1. Turn fuel oil supply off at the burner.

2. Set the thermostat or controller above room

temperature to call for heat.

3. Watch for ignition spark immediately or following pre-

purge.

4. Time length of ignition operation.

5. After the module locks out, open fuel oil valve.

6. Set the thermostat below room temperature and wait

five minutes.

7.

Set thermostat above room temperature. Reset the

burner by pushing the button on the back of the oil

burner. Operate system through one complete cycle to

ensure all controls operate properly.

Содержание reflect-o-ray eds 3.5

Страница 4: ......

Страница 57: ...Reflect O Ray Oil Fired EDS 3 5 Installation Operation Service Combustion Research Corporation Page 53 NOTES...

Страница 60: ......

Страница 61: ......