Reflect-O-Ray

®

Oil Fired EDS 3.5

Installation, Operation & Service

Page 12

Combustion Research Corporation

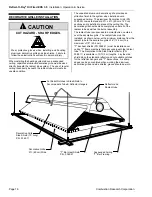

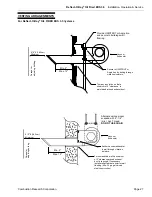

SEISMIC RESTRIANT SUSPENSION METHODS

For standard seismic restraint such as earthquake prone

areas, install seismic restraint chain or cable as shown

below. If high winds can be encountered in the building,

such as found in airplane hangers where opposing doors

are simultaneously open, or system is installed near or

below the door opening, additional support of the radiant

tube and reflector network will be required. See the

“

Seismic Suspension For High Wind Applications

” below

for details. If there are any questions regarding what

method is best suited for your application consult your

sales representative or contact the factory. If the system

is a straight system (no elbows or tee's), apply an anti

sway chain or wire rope which is parallel to the radiant

tube at approximately the middle of the run.

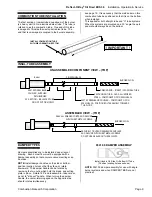

Install the cable clamp

approximately 3” from

the edge of the reflector.

Clamp tight to prevent

chains or cables from

sliding on hanger

Seismic Restraints

Use chain or min. 1/8”

aircraft cable

30° Min.

45° Max.

30° Min.

45° Max.

30° Min.

45° Max.

30° Min.

45° Max.

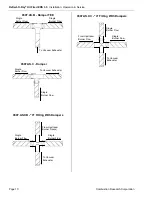

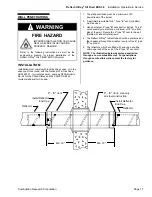

SEISMIC RESTRAINT FOR HIGH WIND APPLICATIONS

In high wind conditions it is recommended that

seismic restraints and reflector retention wire be

installed. See details below for recommended

installation of seismic restraint and anti sway

retention chains (wire rope). The vertical threaded

rod shall be attached and suspend the reflector

hangers at intervals of eight to ten feet (8' - 10'). At

least one vertical threaded rod shall be placed at

every elbow and/or tee connection. The threaded

rod is used to prevent the system from lifting during high

wind conditions, the chain or wire rope will keep the

system from swaying from side to side. When connecting

threaded rod to "Z" purlin use beam clamp or drill a hole

through "Z" purlin and secure with two 3/8" nuts and a lock

washer. If the system is a straight system (no elbows or

tee's), apply an anti sway chain or wire rope which is

parallel to the radiant tube at approximately the middle of

the run.

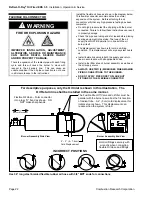

Punch or drill a small hole (approximately 1/8”) in the reflector near the

reflector hanger. Insert an appropriate length of 14 Ga. galvanized wire

through this hole and encircle the combination hanger. Maintain a loose loop

around the hanger, this will allow for expansion of the system. Twist the ends

of the wire together and trim as required. This retention wire may be installed

on both sides, or edges of the reflector for severe wind conditions.

30° MIN.

45° MAX.

30° MIN.

45° MAX.

Содержание reflect-o-ray eds 3.5

Страница 4: ......

Страница 57: ...Reflect O Ray Oil Fired EDS 3 5 Installation Operation Service Combustion Research Corporation Page 53 NOTES...

Страница 60: ......

Страница 61: ......