13- 11- 605

Page 29

Never paint, lubricate or alter a relief

valve. Do not plug vent or restrict dis-

charge.

Operation of unit with improper relief

valve setting can result in severe per-

sonal injury or machine damage.

Insure properly set valves are in-

stalled and maintained.

Blowdown Valve

(FIGURE 4-- 3) -- This valve normal-

ly is used for control functions, but also serves to relieve

reservoir pressure following a shutdown. See addition-

al blowdown valve description below.

Discharge Check Valve -

(FIGURE 1-- 4, page 3) -- A

check valve to prevent back flow of air from the shop

air line when the unit stops, unloads, or is shut down.

Inlet Valve

(FIGURE 1-- 3, page 2, and FIGURE 4-- 4,

page 30, this section) -- The Inlet valve opens to load

and closes to unload the compressor. At shutdown, the

inlet valve closes to prevent the back flow of air.

The inlet valve position is controlled by air pressure in

its piston cylinder, which is controlled by the AUTO

SENTRY

R

-- W through the magnetic unloader solenoid

valve.

Magnetic Unloader Solenoid Valve

-- This valve

controls the position of the inlet valve in response to the

AUTO SENTRY

R

-- W. With the valve de-- energized,

the normally open unloader valve allows control pres-

sure to the inlet piston to close the inlet valve. If the

valve is energized, control pressure is relieved from the

inlet piston to allow the valve to open.

Control Air Pressure Regulator

-- This pressure reg-

ulator is used to supply a constant and low control pres-

sure to prevent damage to the inlet valve from “slam-

ming.” The regulator should be set for 25-- 30 psig.

Seal Purge Air Pressure Regulator

-- This pressure

regulator is used to provide a constant and low control

pressure for proper seal operation.

The regulator

should be set for 5-- 7 psig.

Inlet Seal Buffering Water Pressure Regulator

--

This pressure regulator is used to provide a constant

and low pressure water supply for proper operation of

FIGURE 4--3 -- BLOWDOWN VALVE

compressor inlet seals. The regulator should be set for

2-- 3 psig.

Shuttle Valve

(FIGURE 4-- 5, page 30) -- Also known

as a double check valve, the shuttle valve is a device

which will take two (2) supply signals and allow the one

with the highest pressure to pass through. The shuttle

valve is used to provide control air pressure from either

the reservoir or plant air system, as required during dif-

ferent operating conditions.

Blowdown Valve

(FIGURE 4-- 3)

-- The blowdown

valve is a two-- way solenoid valve which is piped into

the water reservoir outlet ahead of the discharge check

valve. When the solenoid is de-- energized, the valve

opens and the coolant system is blown down. When

the solenoid is energized, the valve closes to allow the

coolant system to pressurize. A control air check valve

is provided to ensure that the inlet valve is closed during

blowdown.

System Pressure Transducer

-- This transducer is

connected after the discharge check valve. It converts

the pressure in the plant air system into an electrical

signal for use by the AUTO SENTRY

R

-- W controller for

control.

Reservoir Pressure Transducer

-- This transducer

is connected to the coolant system. Its signal is used

to prevent loaded starts, monitor coolant pressure, and

monitor the condition of the water filter.

Injection Pressure Transducer

-- This transducer is

connected to the coolant system. Its signal is used to

Содержание ROTORCHAMP RCOF20

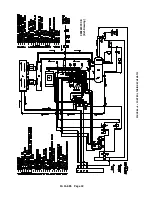

Страница 13: ...13 11 605 Page 4 FIGURE 1 6 AIR WATER SCHEMATIC 300EWC797 B Ref Drawing ...

Страница 16: ...13 11 605 Page 7 DECALS 206EAQ077 300EWC077 301EWC077 211EAQ077 207EAQ077 ...

Страница 17: ...13 11 605 Page 8 DECALS 216EAQ077 206EWD077 222EAQ077 221EAQ077 208EAQ077 ...

Страница 31: ...13 11 605 Page 22 FIGURE 4 2 FLOW CHART FOR SET UP PROGRAMMING 300EWC1255 Ref Drawing ...

Страница 41: ...13 11 605 Page 32 FIGURE 4 6 CONTROL TUBING SCHEMATIC 300EWC797 B Ref Drawing ...

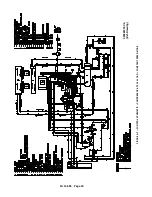

Страница 43: ...13 11 605 Page 34 FIGURE 4 8 CONTROL SCHEMATIC COMPRESSOR UNLOADED CONSTANT SPEED MODE 303EWC797 A Ref Drawing ...

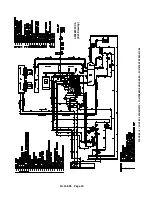

Страница 45: ...13 11 605 Page 36 FIGURE 4 10 WIRING DIAGRAM FULL VOLTAGE 301EWC546 A Ref Drawing ...

Страница 46: ...13 11 605 Page 37 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 302EWC546 A Ref Drawing ...

Страница 47: ...13 11 605 Page 38 FIGURE 4 12 AUTO SENTRY W CONTROLLER DISPLAY ...

Страница 49: ...13 11 605 Page 40 FIGURE 5 1 OIL LEVEL SIGHT GLASS 306EWC797 A Ref Drawing ...

Страница 50: ...13 11 605 Page 41 FIGURE 5 2 FLOW DIAGRAM AIR COOLED 300EWC797 A Ref Drawing ...