13- 11- 605

Page 18

SECTION 4

CONTROLS & INSTRUMENTATION

GENERAL DESCRIPTION

-- The Champion Rotor-

Champ

R

waterflooded rotary screw compressor is pre-

wired with all controls, motor, and starter for the voltage

and horsepower at the time of ordering. It is necessary

only to connect the compressor unit to the correct pow-

er supply, to the shop air line, and to the appropriate wa-

ter supply. A standard compressor unit consists of the

compressor, water reservoir, water cooling system and

filters, lubrication reservoir, motor type as specified,

NEMA 12 starter / control box, and control components

as described below.

This

compressor

unit

features

the

AUTO

SENTRY

R

-- W controller, which integrates all the con-

trol functions under microprocessor control. Its func-

tions include safety and shutdown, compressor regula-

tion, operator control, and advisory / maintenance

indicators. The keypad and display provide the opera-

tor with a logical and easily operated control of the com-

pressor and indication of its condition.

AUTO SENTRY

R

- W OPERATION

Normal operation is controlled by the keys in the OP-

ERATE island of the AUTO SENTRY

R

-- W controller.

Prior to starting, press the [STOP/RESET] key to place

the controller into its READY state (as indicated on the

display). Press the [RUN] key to start the compressor.

The green LED will light near the automatic operation

symbol whenever operation is enabled.

The [STOP/RESET] key may be pressed at any time

to stop the compressor under normal conditions. If the

compressor has been running, the reservoir pressure

is relieved before stopping the motor. The display will

count down to zero during the normal stop.

An optional control may be wired into the AUTO

SENTRY

R

-- W controller to interrupt and restart the unit

based on controls by others. When stopped by these

controls, the display indicates remote stop.

Automatic restarting or electrical

shock can cause injury or death.

Open, tag and lockout main discon-

nect and any other circuits before

servicing the unit.

In any mode, the compressor will start only if reservoir

pressure is below 5 psig (0.3 bars). The display will in-

dicate if the control is waiting for a reservoir blowdown,

along with the remaining pressure. The controls also

delay initial loading of the compressor until a startup

delay has been completed.

Constant Run Mode Operation

-- This mode is best

used in applications where there are no long periods of

unloaded operation, or for minimum response time to

sudden demands. The compressor unit will start and

run continuously, using its controls to load and unload

the compressor. This matches average delivery to de-

mand.

When the air demand is less than the compressor ca-

pacity, the air pressure rises to the unload point of the

control. It will then unload (but not blow down) and will

not deliver any air to the system. Air demands are sup-

plied by air stored in receivers and plant piping. When

the pressure falls to halfway between the unload and

load pressures, the W controller again fully loads the

compressor.

When first starting, the controller will keep the com-

pressor fully unloaded and blown down until the system

pressure drops below the load pressure. Once loaded,

the reservoir will remain fully charged, regardless of de-

mand. Responses to demand are thus immediate, and

system pressures will be maintained in the upper por-

tion of the programmed pressure band.

Low Demand Mode Operation

-- The low demand

mode reduces power consumption by relieving pres-

sure in the reservoir during unloaded operation. This

mode is best used where there is moderate air storage

and there are unloaded periods during the day, but fre-

quent motor starting and stopping is undesirable. Dur-

ing periods of moderate to high demands, this mode is

identical to the constant-- run mode described above.

During low demand periods, the controller will also

open the blowdown valve while unloaded, to minimize

the motor load. A timer is reset when this occurs. Plant

demands and control air pressure is supplied from the

plant air system while the compressor is unloaded.

When the system air pressure drops to the load pres-

sure, the blowdown valve recloses and the compressor

fully loads.

Subsequent blowdown periods are not allowed until the

timer has completed its cycle. This cycle eliminates

frequent blowdowns while the plant has high air de-

mands, and the energy required to re-- pressurize the

reservoir. The timer is adjustable from 1 to 20 minutes.

Automatic Mode Operation

-- This mode provides

automatic start and timed stop, and is best used in ap-

plications with long unloaded periods and adequate

Содержание ROTORCHAMP RCOF20

Страница 13: ...13 11 605 Page 4 FIGURE 1 6 AIR WATER SCHEMATIC 300EWC797 B Ref Drawing ...

Страница 16: ...13 11 605 Page 7 DECALS 206EAQ077 300EWC077 301EWC077 211EAQ077 207EAQ077 ...

Страница 17: ...13 11 605 Page 8 DECALS 216EAQ077 206EWD077 222EAQ077 221EAQ077 208EAQ077 ...

Страница 31: ...13 11 605 Page 22 FIGURE 4 2 FLOW CHART FOR SET UP PROGRAMMING 300EWC1255 Ref Drawing ...

Страница 41: ...13 11 605 Page 32 FIGURE 4 6 CONTROL TUBING SCHEMATIC 300EWC797 B Ref Drawing ...

Страница 43: ...13 11 605 Page 34 FIGURE 4 8 CONTROL SCHEMATIC COMPRESSOR UNLOADED CONSTANT SPEED MODE 303EWC797 A Ref Drawing ...

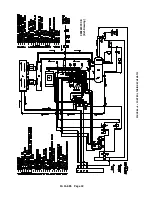

Страница 45: ...13 11 605 Page 36 FIGURE 4 10 WIRING DIAGRAM FULL VOLTAGE 301EWC546 A Ref Drawing ...

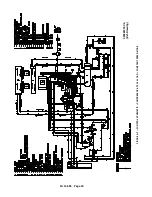

Страница 46: ...13 11 605 Page 37 FIGURE 4 11 WIRING DIAGRAM WYE DELTA 302EWC546 A Ref Drawing ...

Страница 47: ...13 11 605 Page 38 FIGURE 4 12 AUTO SENTRY W CONTROLLER DISPLAY ...

Страница 49: ...13 11 605 Page 40 FIGURE 5 1 OIL LEVEL SIGHT GLASS 306EWC797 A Ref Drawing ...

Страница 50: ...13 11 605 Page 41 FIGURE 5 2 FLOW DIAGRAM AIR COOLED 300EWC797 A Ref Drawing ...