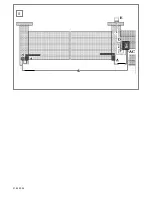

2.1 FRONT SUPPORT ASSEMBLY

Fig. 4 - 7

After the plate fixation, install the actuator the pivot (Fig.1).

Then provide for the “STOP” installations on the ground.

• Open the gate wing till the desired position is reached

• Now the front plate can be fixed following this scheme.

Proceed as follows:

1. Open the wing till the STOP is reached.

2. Lay the actuator on the gate with the rod COMPLETELY INSIDE

(position perfectly horizontal).

3. Fit the plate, as shown in the illustration, and test while closed.

4. Then fix the plate to the gate by means of screws or by welding it

to the gate.

It is advisable to check the good operation of the movement by

opening the gate wings manually. Do not exceed the maximum length

of 1100mm.

2.2 SECOND ACTUATOR ASSEMBLY

Repeat the operation for the other gate wing, following the same steps

2.0 and 2.1.

Note: Fixation measures of the second actuator shall be the

same as the first ones.

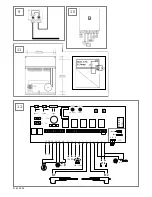

3.0 WIRING

Fig. 8

AC:

A.C. LINE INLET

A:

12V ELECTROMECHANICAL PISTONS -L/R

B:

ELECTRONIC CONTROL EQUIPMENT FIG. 13

D:

KEYSWITCH (OPTIONAL)

E:

FLASHING LAMP 12V MAX. 10W

1: Connection cable motor M1 - bipolar cable 1.5mm

2

cross section

2: Connection cable motor M2 - bipolar cable 1.5mm

2

cross section

3: Connection cable Flashing cable (not included)

4: Connection cable Keyswitch (not included)

5: Connector blocks (not included). Minimum height above ground

20cm (Fig. 9)

6: Underground cable duct (not included)

3.1 STANDARD ELECTRONIC CONNECTIONS

Fig. 12

1+3

Start key contact normally open N.O. It can be used with

daily timers for the opening at set hours. Both wings will

open.

12+13

One wing (M1)will open.

1+2

Safety photocell, normally closed contact N.C.

Caution: Pay attention in case photocells were not used,

close the circuit of terminals 1-2 by means of a jumper.

6+7

M1 First motor with delayed start in opening

(6 blue/7 brown) (stationary wing)

4+5

M2 Second motor with delayed start in closing

(4 blue/5 brown) (automated wing)

8+9

12 Volt maximum 10 Watt Flashing lamp

10+11

Output for photocell supply 12 Volt. DC

14+15

E-lock connection

16+17

External connection (Light feature)

3.2 SPECIAL CONNECTIONS

Fig. 12

HOW TO PROCEED:

1. First of all make the low voltage connections: Motors, Flashing

lamp, Keyswitch and possibly optional connections as photocells,

antenna.

2. Then connect the supply line to the 230V 50Hz transformer

(Fig. 11).

3. LED LD1 (green) will light up.

4. At the first START pulse the gate will move.

Caution: This operation shall be carried out with closed

wings, consequently the first operation will be the gate

opening.

3.3 SETTINGS

Fig. 12

Automatic close ON:

• Press and hold button P3, until the LED (red) will light up.

• Release button

• Wait for the desired time (open time - door open)

(approx. 120 seconds.)

• Again, press button P3

During the opening cycle it is not possible to interrupt the movement

with a push button or transmitter. The actuator will stop during the

closing cycle and opens again.

Automatic close OFF:

• Press button P3 at least 10 seconds. First, the red LED will lighten

up and will turn off after approx. 10 seconds.

Force adjustment: The electronic control automatically adjusts to the

necessary force. If adjustage (in case of windy conditions) should be

necessary, move the wings to the schwergängiste position of the gate.

• Press button P2 until the green LED lightens up.

• The electronic control will test the the necessary force for

approx. 20 seconds. The green LED will turn off.

According to the regulations for automated shutters, doors and

gates - the force on the main closing edge may not exceed 150N

(15kg).

Caution: Due to weather conditions the Force adjustment

can vary.

Routine wing maintenance will reduce mechanical and closure

problems.

F10

Transformer safety fuse 0.8A T

F1

Battery safety fuse 10A

F2

Facilities safety fuse 5A

3.4 SPECIAL ELECTRIC CONNECTIONS:

PHOTOCELLS

The protection system by means of photocells (100263) is composed

of one or more PAIRS of devices, one of them is the TRANSMITTER

and the other is the RECEIVER (Fig.14-15).

The first transmits an invisible infrared ray picked up by the receiver; in

case the ray were interrupted the equipment will open a relay which

shall transmit a signal to the programmer that shall provide to invert

the motors operation direction during the wings closing.

Caution: Carry out connections according to diagram Fig. 14. In

case photocells were more than ONE pair, carry out connection

in SERIES. Provide for a digging in the ground sufficient to lay a cable

duct crossing the gate width.

1.

Cable having a minimum cross section of 0.5mm

2

SHALL BE

PROTECTED BY A PROPER SHEATH.

2.

In case of double safety device, provide for a DOUBLE PASSAGE.

3.

Position the receiver in front of the transmitter at the same height

(40/60cm).

4.

The red led off indicates a perfect alignment.

5.

Install the photocells cables far from cable ducts to avoid

interference.

3-GB

709145B-GB - 05.2004

Содержание WGO200

Страница 23: ...ca 700mm 1 2 3 4 5 01 05 2004 ...

Страница 24: ...maximal 1100mm 6 1100mm max 7 01 05 2004 ...

Страница 25: ...3 4 8 01 05 2004 ...

Страница 27: ...13 2 1 2 1 Module 433MHz 418MHz 27MHz Logic Board 01 05 2004 ...

Страница 28: ...12V 12V NC min 0 5 mm 2 NC C NO 10 11 1 2 10 11 1 2 5m max 14 15 01 05 2004 40 cm ...