47

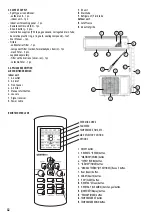

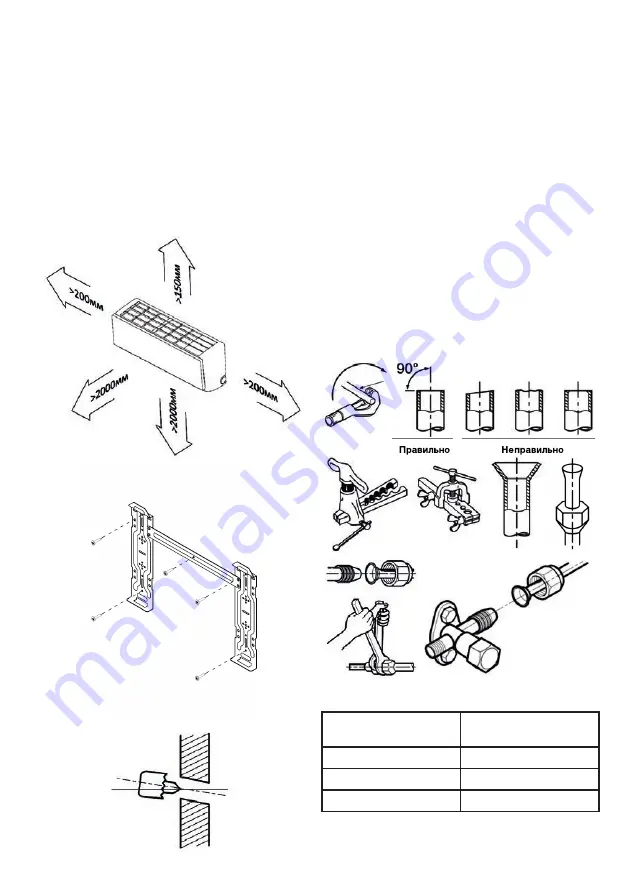

INDOOR UNIT LOCATION SELECTION

Select a location where the surface can support the weight and

vibration of the indoor unit. There should be a sufficient free space

for the installation and subsequent maintenance of the indoor unit.

There should be enough free space in order not to restrict air

circulation and no obstructions on the air discharge side. The

indoor unit should be located at least 1 meter away from radio or TV

receivers in order to minimize the probability of sound and picture

distortion during operation. The impact of direct sunlight and other

heat sources should be minimized. The indoor unit should be installed

perfectly level. The mounting bracket of the indoor unit should be

securely fastened.

INDOOR UNIT MOUNTING DIMENSIONS

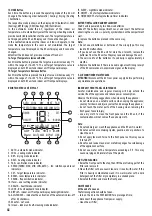

MAKING THE HOLE IN THE WALL

Select the location for the wall hole.

Before drilling the hole make sure that there are no embedded

electrical cables or pipelines inside the wall.

Drill a hole, 60 to 80 mm in diameter, at a slight angle towards the

outdoor unit. Insert a liner if necessary.

CONNECTING INTER

-

UNIT ELECTRIC CABLE AND POWER SUPPLY CABLE

Refrigerant Tube Flaring

Properly cut the copper tube of the required length with a tube cutter.

Remove all burrs from the cut edge of the tube. When deburring the

cut hold the tube with the cut end facing down to prevent metal

shavings from getting inside the tube. Put a tapered ring nut of the

proper size on the tube. Be careful as you will not be able to install

the ring nut after flaring the tube end. Flare the tube end using a

specialized tool and observing all required procedures relevant for

this type of work. Check the resulting flare, it should have the same

length and a smooth edge around the whole circumference and a

shiny inner surface without scratches. If the flare is defective, cut the

flared end away and repeat the flaring process.

Refrigerant Tube Connection

Align the pipelines and tighten the tapered ring nut by hand to a stop.

Hold the nozzle from rotating with a spanner and tighten the ring

nut with a torque wrench, observing the torque specified in the table.

I

Table 2

Tube size

(mm)

Torque

(N, m)

φ 6.35 (1/4”)

15~25

φ 9.52 (3/8”)

35~40

φ 12.70 (1/2”)

45~60