IOM-HP-S-DIFF

5

5. Clean debris from within the regulator body

(1) cav i ty. Make certain the old cylinder gas ket

(18) is cleaned out of the body (1) recess.

Clean all parts to be reused according to

owner's procedures.

6. Reinstall a new cylinder gasket (18). Press

firmly and evenly into place using the cyl in der

(16). Do not use a “homemade” cylinder

gas ket. Pipe seal ant may be lightly coated to

the gasket (18) surfaces prior to installation.

In spect to see that cylinder gasket (18) is

com plete ly pressed into place and cylinder

(16) is cen tered with body cap (5) opening.

7. Install a new back up ring (27) and quad ring

(26) on piston (15). Make certain the teflon

back up ring (27) will insert the body cap (5)

first, before the quad ring (26) (See Figure 3).

Make sure the quad ring (26) is on straight with

no twist

.

Use a good grade lightweight grease

on both ring seals (26,27). Slide piston (15)

into cyl in der (16).

8. Place piston spring (17) into the cavity of the

piston (15).

9. Insert new body cap o-ring (25) into groove of

body cap (5). Use a good grade lightweight

grease on body cap o-ring (25). Use pipe

thread seal ant ap plied to the body cap (5)

threads. Screw body cap (5) into body (1).

Impact until body cap (5) is metal to metal

against body (1) at the body cap (5) shoulder.

D. Bench test for suitable operation

(Test Fluid:

Air or compressed gas).

NOTE:

Reg u la tors are not tight shutoff devices.

Even if pres sure builds up beyond setpoint, a

reg u la tor may or may not develop tight shutoff.

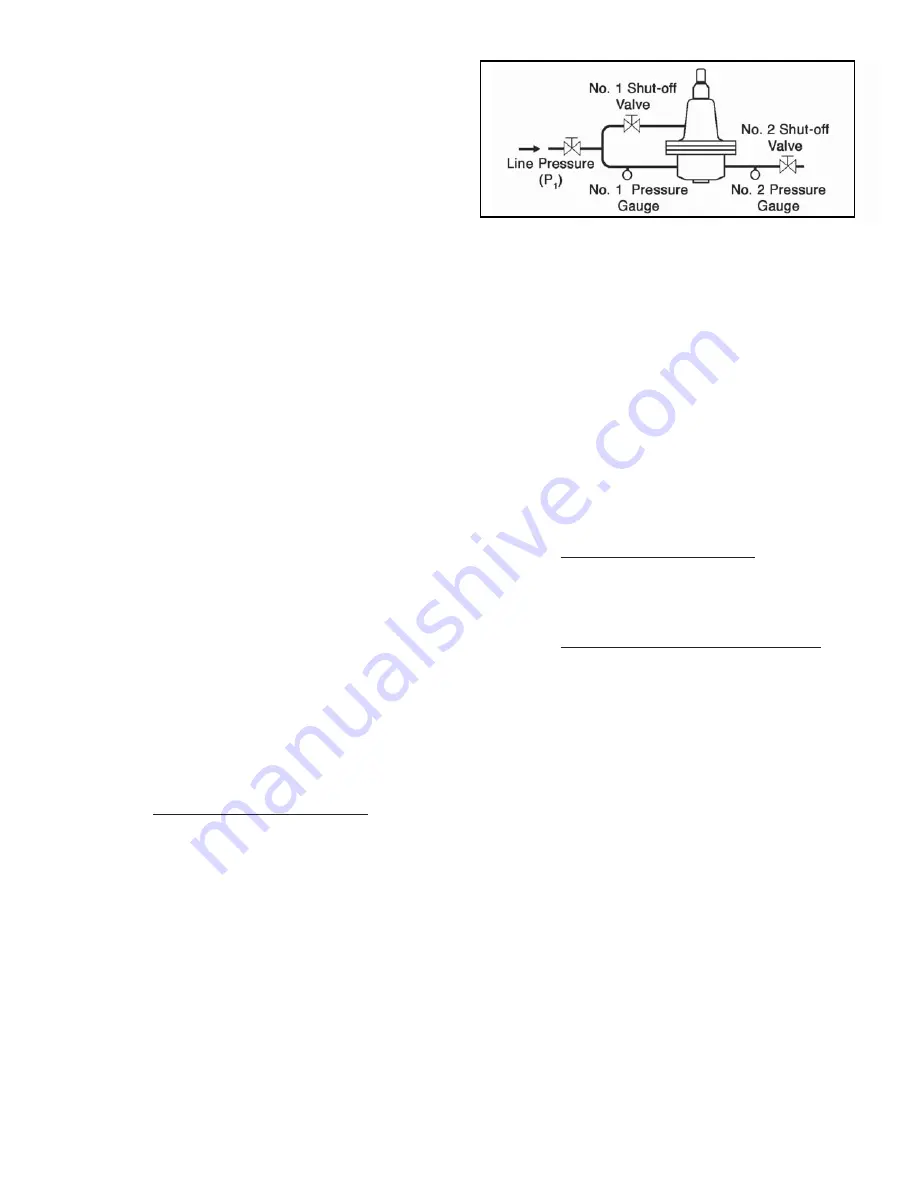

1. Check for internal trim leakage: With No.

1 shut-off valve closed and No. 2 shut-off

valve cracked open, turn on inlet op er at ing

pres sure. Fol low in struc tions from SEC TION

IV-2.

and set a differential pres sure of 20

psig (1.4 Barg) in the down stream line (No.

2 Gauge). Close No. 2 shut-off valve and

check for tight shutoff.

NOTE:

Seat leakage

not to exceed 15 bub bles per minute. Do

not allow ex ces sive build up if seat leak age

ex ists (crack open No. 2 shut-off valve to

pre vent build up)

. If seat leak age is ex ces sive,

pro ceed with the fol low ing steps to de ter mine

location of leak:

a. Close No. 1 shut-off Valve.

b. Turn off inlet operating pressure (P

1

).

c.

Re

move entire topworks per SEC TION

VI-B., steps 1-5.

d. Turn inlet operating pressure (P

1

) on.

e. Spray liquid leak detector in the space

be tween cylinder (16) and body (1) to

check for cylinder gasket (18) leakage.

f. Pour a few drops into recess along pis ton

post (15) to check for seat leakage.

g. Fill the recess to check for quad ring (26)

leakage.

Once location of leak is detected, proceed

to SECTION VII-6 for Cause/Remedy and

SECTION VI-C. for internal trim replacement.

After leak is remedied, proceed to SEC TION

VI-B., steps 8-15 to re as sem ble top works.

2. Check regulator performance: With Step No.

1 con di tions met, open and close No. 2 shut-

off valve to check reg u la tor's per for mance for

smooth ness and re peat abil i ty.

3. Proof test to check for external leakage:

a. Build inlet pres sure to 1-1/2 times

max i mum out let pres sure; but not to

exceed 1-1/2 times the Max. Out let and

Spring Cham ber Pressure Rat ing (See

HP-S-DIFF TB, Ta ble 2). Close No. 2 shut-

off valve and crack open No. 1 shut-off

valve until full inlet pressure exists in the

spring cham ber (2) and down stream line

(No. 2 gauge will reg is ter same pres sure

as No. 1 gauge).

b. Spray the entire regulator with a liquid leak

detector and visually inspect for external

leak age. Repair unit if leak is detected.

See SEC TION VI MAINTENANCE.

c. To relieve all pressures simultaneously

(pre vent ing diaphragm (12) damage

due to ex ces sive

∆

P across diaphragm

(12)), crack open No. 2 shut-off valve and

shut off inlet pres sure. This will uniformly

bleed off all pres sure con tained within the

reg u la tor.

4. Return to Section II for Installation and Sec tion

IV for Startup.

Figure 2:

Recommended Bench Test

Piping Schematic for HP-1+6+S