IOM-HP-S-DIFF

3

6.

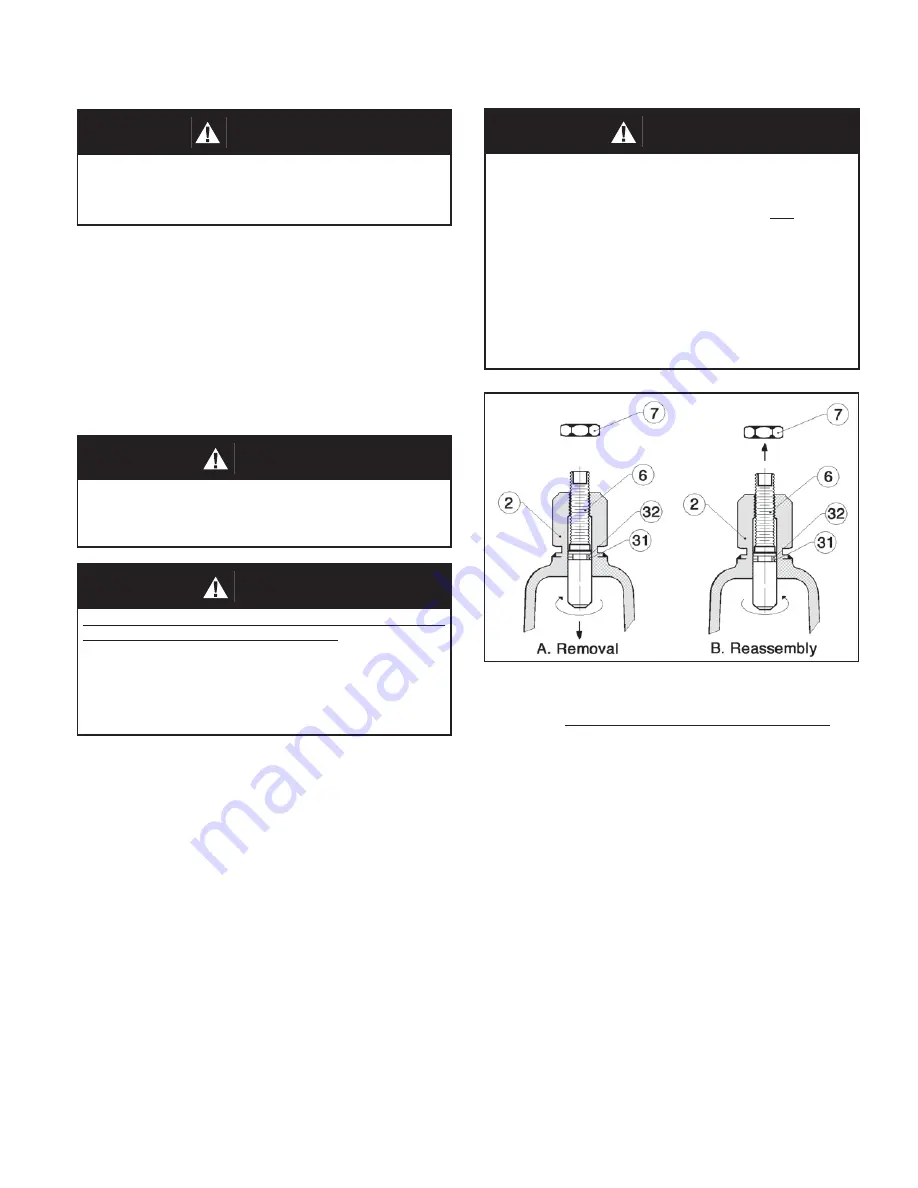

Adjusting screw (6) o-ring inspection

:

a. With locknut (7) and closing cap (28)

re moved, turn adjusting screw (6) CW

as far as possible by turning flats on

top end. Care ful ly reach inside spring

cham ber (2) and grasp ad just ing screw

(6) by hand.

NOTE:

For 1/2" (DN15)

and 3/4" (DN20) size reg u la tors a small

piece of plastic tubing with a 3/4" (19 mm)

inside di am e ter may be used to grasp the

ad just ing screw (6).

Complete ad just ing

screw (6) removal by ro tat ing CCW. See

Figure 1.

b. Inspect the backup ring (32) and quad ring

(31) for wear. If nicked or torn - replace.

NOTE:

Make certain the Teflon backup

ring (32) will insert into spring cham ber (2)

before the quad ring (31). (See Fig ure 3

blow-up illustration). Make sure the quad

ring (31) is on straight with no twist. Use

a good grade light weight grease on both

ring seals (31,32).

A. General:

1. Maintenance procedures hereinafter are

based upon re mov al of the regulator unit from

the pipeline where in stalled.

2. Owner should refer to owner's procedures for

removal, handling, cleaning and dis pos al of

nonreusable parts, i.e. gaskets, etc.

3. Refer to Figure 3 for view of regulator.

WARNING

SPRING UNDER COMPRESSION. Relieve spring

compression prior to re mov ing diaphragm flange bolts.

Fail ure to do so may result in flying parts that could cause

per son al injury.

CAUTION

DO NOT AT TEMPT TO REMOVE ADJUSTING SCREW (6)

FROM TOP OF SPRING CHAM BER (2). The ad just ing

screw (6) is threaded upward from inside the spring

chamber (2). The CCW ro ta tion used to relieve range

spring (14) tension will come to a stop. At the stop ping

point, do not apply any torque to ad just ing screw (6) or

dam age may occur and ren der the unit in op er a ble.

See

Figure 1.

CAUTION

When body flange hardware (9,23,34,35) is re moved

from this unit it should al ways be replaced with new.

The new hardware (9,23,34,35) must have the prop er

grade spec i fi ca tion iden ti fi ca tion markings and meet the

following standards:

1. All cap screws (23) and flange stud nuts (9) must have

"heavy hex heads".

2. All studs (34,35) and cap screws (23) must comply with

or exceed the requirements of ASTM A-193, Grade B7.

3. All flange stud nuts (9) must comply with or exceed

the requirements of ASTM A-194, Grade 2H.

New body flange hardware (9,23,34,35) may be pur chased

from Cashco, Inc. or through the OEM.

Figure 1:

Adjusting screw (6) o-ring inspection.

B. Diaphragm Replacement:

1. Securely install the body (1) in a vise with the

spring chamber (2) directed upwards.

2. To relieve range spring (14) compression,

re move clos ing cap (28) by turning CCW.

Re move lock nut (7) by turning CCW. Turn

ad just ing screw (6) CCW until range spring

(14) compression is relieved.

NOTE: See

CAUTION C)

.

3. Draw or embed a match mark between body

(1) casting, body spacer (24), and spring

cham ber (2) casting along flanged area.

4. Remove all body flange hardware (9,23,34,35).

5. Remove spring chamber (2), range spring

(14), spring button (4), pressure plate (3), body

spacer (24), diaphragm (12), and o-rings (30).

WARNING

SYSTEM UN DER PRES SURE. Prior to per form ing any

maintenance, isolate the reg u la tor from the system and

relieve all pres sure. Failure to do so could result in

personal injury.

SECTION VI

VI. MAINTENANCE