Ductable air-cooled scroll

chillers and heat pumps

16

Minimum installation volume

The electronic control for these units incorporates an auto-adaptive

control for the compressor operating time based on the time set for

anti-short-cycle.

This control reduces the number of times the compressor is started

up and permanently adjusts the system's thermal inertia, favouring

the reduction of the minimum volume of water in the installation. The

size of the buffer tank can also be decreased since the unit will be

stopped for less time.

Where:

V

inst

Installation volume (l)

V

inst

Expansion vessel volume (l)

V

1

Initial volume of 1kg of water (at water temperature with the machine stopped)

V

2

Final volume of 1kg of water (at water temp. with the machine at normal speed)

P

f

Final network pressure (safety valve pressure in bars + 1)

P

i

Initial network pressure (absolute

fi

lling pressure of the installation in bars)

Note:

If the hydraulic circuit has a buffer tank, its volume must be taken

into account for this calculation.

• Volume occupied by 1kg of water at different temperatures:

Maximum installation volume

The water capacity for the installation obtained from this equation

corresponds to the maximum that

the installation allows based on the

expansion vessel assembled.

Installation water volume

Temperature (ºC) Volume (l)

Temperature (ºC) Volume (l)

0

1,00013

50

1,0121

4

1,00000

60

1,0171

10

1,00027

70

1,0227

20

1,00177

80

1,0290

30

1,00435

90

1,0359

40

1,00782

100

1,0434

f

i

f

vessel

INST

P

V

V

P

P

V

V

⋅

−

−

⋅

)

(

)

(

1

2

=

The calculation of the minimum water volume has been done for nominal

EUROVENT conditions, only in cooling mode. This value is applicable

for the majority of refrigeration applications (group with fan-coil units).

Note

: The buffer tank is indispensable in installations that operate with a

reduced volume of water (group with an air handling unit) or for industrial

processes. For applications with a heat pump, it is recommended that

the buffer tank be used in order to maintain a stable temperature during

the defrosting cycles.

Hydraulic connections

30PA/PH/

PAC/PHC

Minimum

volume (I)

Minimum

fl

ow (m

3

/h)

Maximum

fl

ow (m

3

/h)

90STD

101

2,2

6,2

100STD

120

2,7

7,4

120STD

143

3,1

8,8

160STD

187

4,1

11,3

180STD

204

4,3

12,7

90HEE

107

2,1

6,7

100HEE

132

2,9

8,1

120HEE

152

3,3

9,5

160HEE

189

3,7

11,7

180HEE

210

4,0

12,8

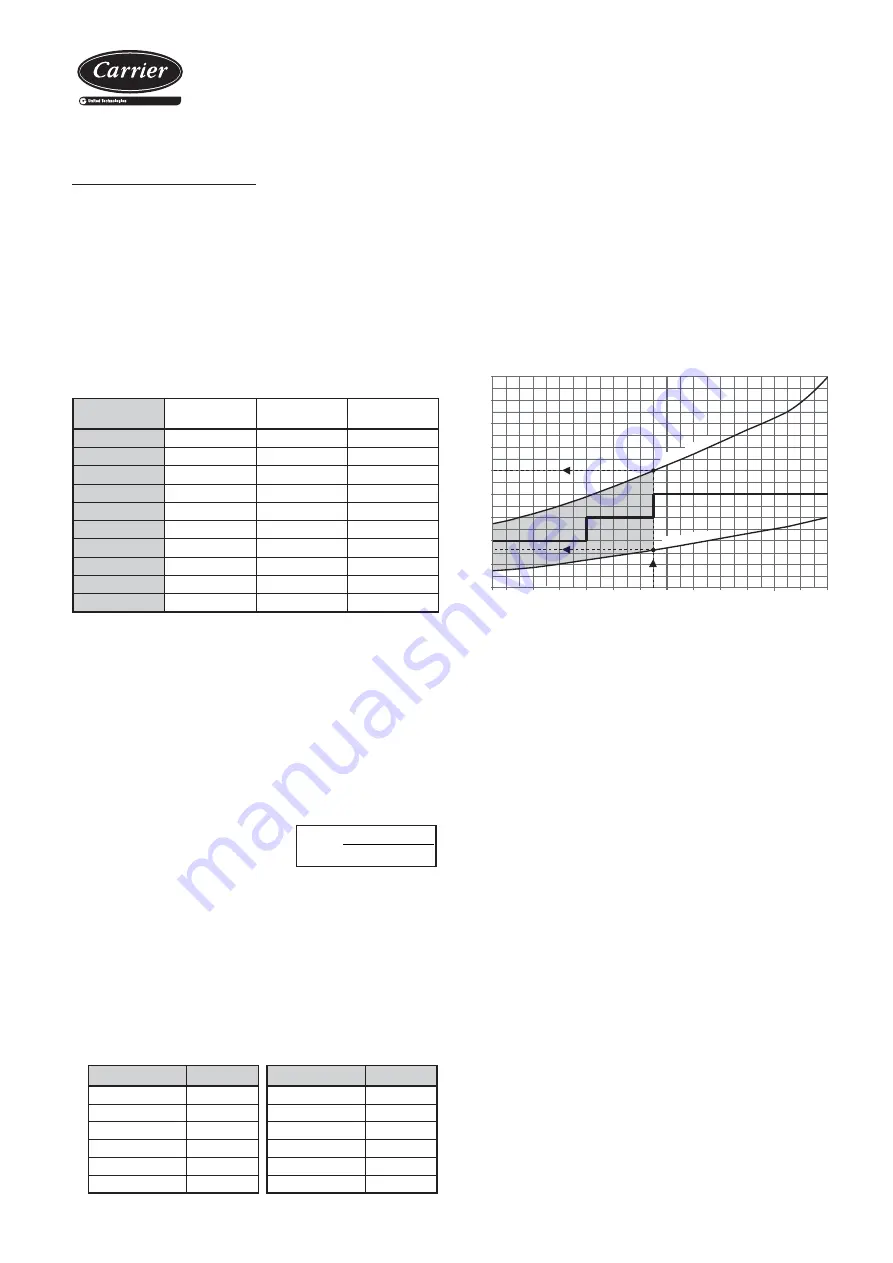

Evaporator operating limits

The curves represent the minimum and maximum admissible

temperature increases based on the outlet (discharge) temperature,

for both pure water and glycol water.

For temperature changes that are not listed between the curves, please

consult.

The minimum outlet temperature for the unit will be +5ºC with pure

water and -7ºC with glycol water.

•

Example

For an outlet water temperature of +5ºC:

Minimum

temp.: 2,6ºC

T. condition 7,6ºC / 5ºC

Maximum

temp.: 6,0ºC

T. condition

11ºC / 5ºC

Anti-freeze protection with glycol water

If a pure product is used for dilution in order to protect the hydraulic

circuit, the following instructions must be followed:

- Do not introduce any of the pure anti-freezing product separately

and then the water in the installation.

- Always prepare the water m anti- corrosion inhibitor

at the correct dosage prior to introducing it into the installation.

9

8

7

6

5

4

3

2

1

10

-7 -6

-4

-2

0

2

4

6

8

10

12

14

16

18

Water outlet temperature °C

Δ

T

Admissible difference between water I/O °C

maximum

Δ

T

minimum

Δ

T

Procedure:

- At minimum, a complete rinsing of the hydraulic installation must be

performed.

- After the

fi

nal rinsing, the installation must be completely drained.

- Introduce the water/anti-freeze/inhibitor mixture and increase the

pressure with a hydraulic pump.

We recommend using a

fi

lling device with a non-return valve for

compliance with the domestic anti-contamination standards. The

device must never in any case be connected to the city network if

the additives used in the hydraulic circuit are not approved by the

Ministry of Sanitation in the country of installation.

- Completely purge the installation.

- Circulate the mixture throughout the entire installation for a minimum

of 2 hours prior to starting up the unit.

- Check the

fi

nal dosage obtained with a densimeter or refractometer.

Содержание 30PA

Страница 2: ......

Страница 4: ......

Страница 34: ...Ductable air cooled scroll chillers and heat pumps 34 Notes...

Страница 35: ......