Jam type

Sensor

Jam description

Staple-free binding error jam (sta-

ple-free binding motor clock sen-

sor error)

PS130

When the staple-free binding motor clock sensor (PS130) cannot detect the encoder

rotation within the specified time after the staple-free binding motor (M116) begins

driving.

Staple-free binding error jam (sta-

ple-free binding HP sensor error)

PS129

When the staple-free binding HP sensor (PS129) does not turn on even when the

specified time elapses after the staple-free binding motor (M116) begins driving.

Staple-free binding error jam (sta-

ple-free binding motor error)

-

When the staple-free binding motor clock sensor (PS130) cannot detect the encoder

rotation within the specified time after the staple-free binding motor (M116) begins

driving and the staple-free binding HP sensor (PS129) turn on even when the speci-

fied time elapses.

Staple-free binding error jam

(binding time-out)

-

When the staple-free binding motor clock sensor (PS130) cannot detect a decrease

in encoder rotation (load occurrence as a result of pinching paper) within the specified

time after the staple-free binding motor (M116) begins driving.

Staple-free binding error jam

(post-bind return operation time-

out)

-

In the return operation after staple-free binding, when the staple-free binding HP sen-

sor (PS129) does not turn off within the specified time after the staple-free binding

motor (M116) begins driving.

Error avoidance jam

-

When any of the following errors is detected during feeding operation.

• Paper end assist motor error (E514)

• Front alignment motor error (E530)

• Stapler shift motor error (E532)

• Staple-free binding motor error (E533)

• Swing guide motor error (E535)

• Rear alignment motor error (E537)

• Stack tray shift motor error (E540)

• escape delivery shift motor error/ flapper motor error / stack delivery/paddle mo-

tor error (E553)

• Safety switch ON error (E554)

• Saddle feed/paddle motor error (E577)

• Paper end pushing guide motor error (E57B)

• Return roller lift motor error (E578)

• Tray auxiliary guide motor error (E583)

• Saddle paper end stopper motor error (E5F0)

• Saddle delivery motor error (E5F1)

• Saddle alignment motor error (E5F3)

• Saddle paper pushing plate/folding motor error (E5F6)

• Saddle switching lever motor error (E5F8)

• Saddle gripper motor error (E5FA)

Paper feed cancellation jam

-

When a paper feed cancellation instruction from the host machine is received for

paper delivered according to a paper reception notification signal.

Manual stack insertion jam

-

When a paper stack is inserted in the manual staple slit while the stapler unit is mov-

ing. This is not detected when the stapler unit is moving to the staple replacement

position.

Sequence jam

-

When the same status does not change even when 1 minute elapses or when a job

is submitted when in service mode.

2. Technical Explanation

72

Содержание Staple Finisher-AA1

Страница 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Страница 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Страница 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Страница 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

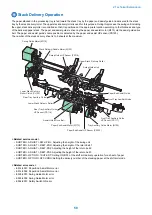

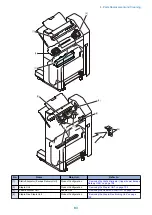

Страница 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

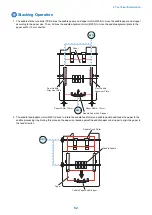

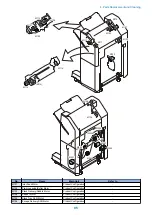

Страница 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Страница 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Страница 178: ...A B Feed Direction Stapling Position Fixing Screw A B Stitcher Unit Fixing Screw Fixing Screw Mark 5 Adjustment 170 ...

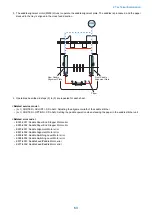

Страница 184: ... Adjsting Phase Angle of the Paddle Unit 1 Put off the belt 1 1 2 Lower the swing roller till its end 5 Adjustment 176 ...

Страница 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

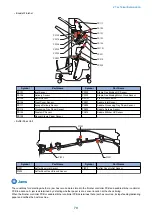

Страница 204: ...4 5 6 7 8 9 7 Installation 196 ...

Страница 205: ...10 7 Installation 197 ...

Страница 210: ...11 NOTE Keep the parts as illustration above Installation of Buffer Pass Unit 1 7 Installation 202 ...

Страница 223: ...2 3 2x 7 Installation 215 ...

Страница 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...