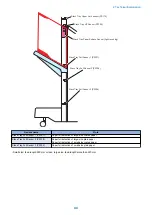

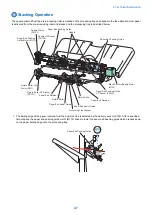

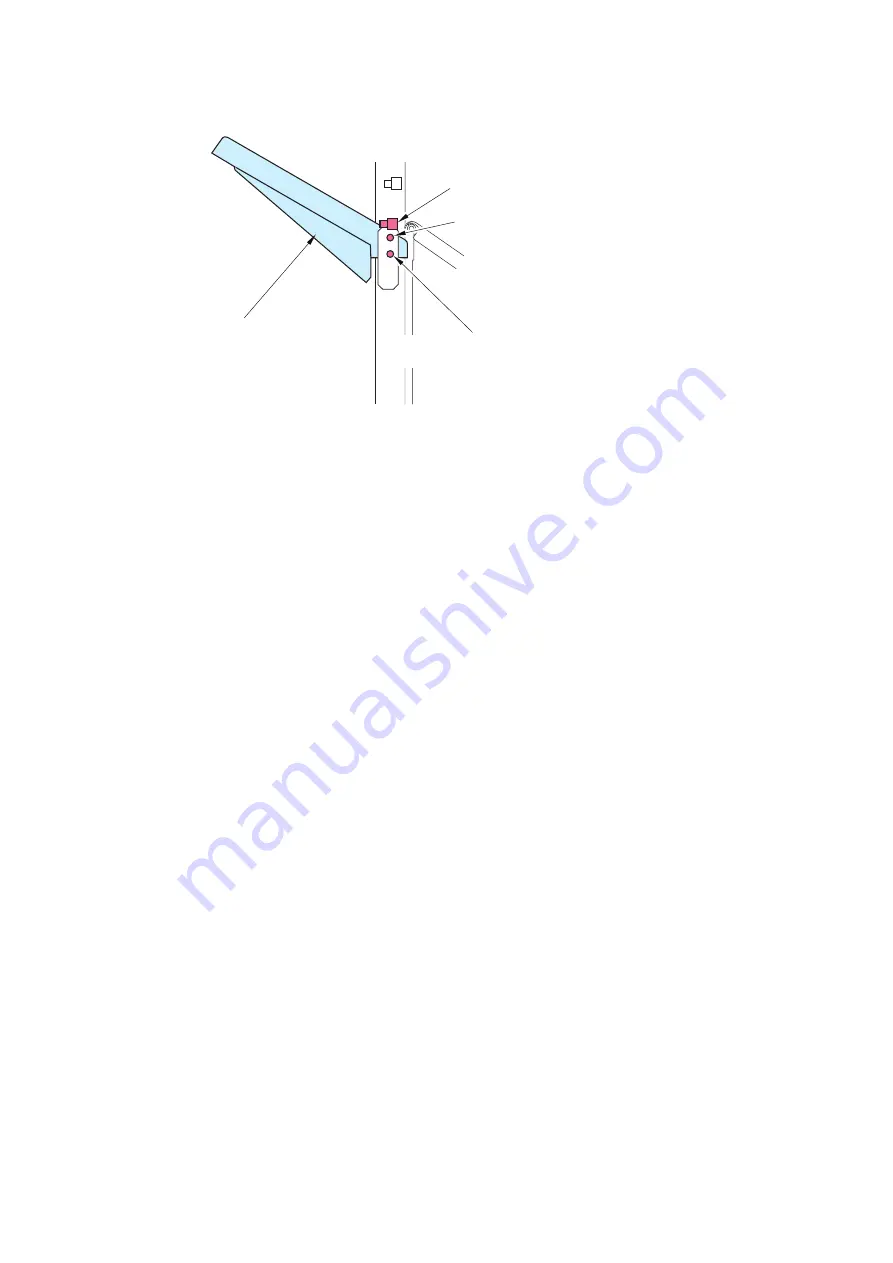

Note that this equipment does not have a paper sensor on the stack tray. Therefore, if the stack tray HP sensor (PS106) is on

when the stack tray paper surface sensor detects the paper surface (top surface of the tray), this equipment decides that the

paper in the stack tray is near empty.

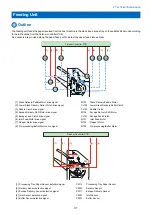

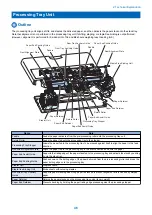

Stack Tray Paper Surface Sensor (Upper)

(light-receiving) (PBA102)

Stack Tray Paper Surface Sensor (Lower)

(light-receiving) (PBA103)

Stack Tray

Stack Tray HP Sensor (PS106)

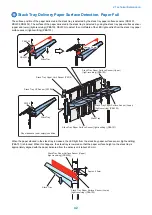

The paper surface detection of the stack tray is not executed in the following conditions. (This is to reduce the sound of tray

movement.)

• From power-on until the initial operation starts

• When an error or jam occurs

• When in sleep mode

• When the tray function is restricted

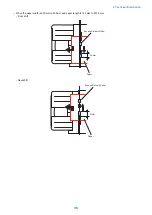

If the stack tray full sensors 1, 2, and 3 (PS107, PS108, and PS109) are on when the LED light from the stack tray paper surface

sensor (light-emitting) (PBA101) is blocked (; the stack tray paper surface sensor detects the paper), this equipment decides that

the paper in the delivery tray is full and stops the paper feed operation.

The following illustration shows the condition that the stack tray full sensor 1 (PS107) detected the paper full on the stack tray.

2. Technical Explanation

43

Содержание Staple Finisher-AA1

Страница 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Страница 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Страница 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Страница 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Страница 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Страница 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Страница 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Страница 178: ...A B Feed Direction Stapling Position Fixing Screw A B Stitcher Unit Fixing Screw Fixing Screw Mark 5 Adjustment 170 ...

Страница 184: ... Adjsting Phase Angle of the Paddle Unit 1 Put off the belt 1 1 2 Lower the swing roller till its end 5 Adjustment 176 ...

Страница 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Страница 204: ...4 5 6 7 8 9 7 Installation 196 ...

Страница 205: ...10 7 Installation 197 ...

Страница 210: ...11 NOTE Keep the parts as illustration above Installation of Buffer Pass Unit 1 7 Installation 202 ...

Страница 223: ...2 3 2x 7 Installation 215 ...

Страница 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...