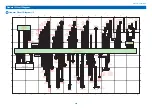

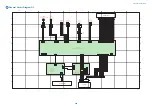

General Circuit Diagram 2/3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

F

E

D

C

B

A

F

E

D

C

B

A

M

M

J2024

M

J2022LH

J2022L

A

B

/B

/A

EJEC

T

M+

T

H

R

U

ST

M+

J2023

J2111

J2102F

J2101M

J2021L

H

J2021L

J2021D

J2022D

J211

J210

J202

EJEC

T

M-

T

H

R

U

ST

M-

GN

D

+5V1

S

SN

S_

EJEC

T

_C

L

K

SN

S_

T

H

R

UST

_C

L

K

GN

D

+5V1

S

/B

B

/B

/A

A

/A

A

B

/B

B

/B

B

/A

A

A

/A

M

M

M

M

J209

J2092D

J2091D

J2092LH

2

3

4

1

J2092L

J2091L

J2091LH

J2096

J2093

J2094

J2095

GN

D

+5V

GN

D

+5V

+5V

GN

D

GN

D

+5V

GN

D

+5V

+5V

GN

D

GN

D

+5V

J201

J205

J2011D

J2051D

J2011LH

J2011L

J2051L

J2051LH

J2054DH

J2054D

J2012DH

J2012L

J2012D

J2054L

J2013

1

2

3

J2016

J2014

J2015

J2053

J2052

J2055

3

2

1

SN

S_

GRP_H

P

SN

S_

JOG_

H

P

SN

S_

KOU

T

AN

_

HP

SN

S-T

H

R

U

ST

_

HP

SN

S_

LAT

C

H

SN

S_

PD

L_

HP

SN

S_

F

OL

D_

JAM

N

.C

OU

T

2

OU

T

1

OU

T

1

OU

T

2

+5V1

S

GN

D

GN

D

+5V

GN

D

+5V

GN

D

+5V

M

J208

J203

J2033D

J2081

J2031DH

J2031D

J2031L

J2033L

J2033DH

J2034

J2032

J2035

SN

S_

F

L

AP_

HP

SN

S_

EN

T

R

Y

SN

S_

UPPASS

SN

S_

RST

P_

LS

SN

S_

F

STP_L

S

SN

S_

ST

P_H

P

J2102M

J2101F

P.2

8 9

1 2

3 4

5 6

7

1 2

3 4

1 2

3

1

2

3

4

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

1

2

3

1

2

3

1

2

3

1 2

8 9

1 2

3 4

5 6

7

10

8 9

1 2

3 4

5 6

7

10

8

9

10

1

2

3

4

5

6

7

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1 2

3

8 9

1 2

3 4

5 6

7

101112

8 9

1 2

3 4

5 6

7

101112

8

9

10

1

2

3

4

5

6

7

11

12

1 2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

8 9

1 2

3 4

5 6

7

10111213

1516

14

8 9

1 2

3 4

5 6

7

101112

8

9

10

1

2

3

4

5

6

7

11

12

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1 2

3 4

5 6

1 2

3 4

5 6

1 2

3 4

1 2

3 4

1 2

1 2

3 4

1

2

3

4

1

2

3

4

1 2

1 2

1 2

1 2

3 4

5 6

1 2

3

1 2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

M205

Saddle

Gripper Motor

M201

Saddle Feed/Paddle Motor

M203

Saddle

Alignment

Motor

M206

Saddle Paper End

Stopper Motor

PS209

Saddle Gripper

HP Sensor

PS207

Saddle Alignment

HP Sensor

PS210

Saddle Paper

End Stopper

HP Sensor

PS208

Saddle Paper Pushing

Plate HP Sensor

PS204

Saddle Unit

Set Sensor

PS206

Saddle Paddle

HP Sensor

PS203

Saddle

Delivery

Sensor

M208

Saddle Stitcher

Motor

PS215

Saddle Stitcher

HP Sensor

PS214

Front Saddle

Stitcher Staple

Sensor

PS213

Rear Saddle

Stitcher Staple

Sensor

PS202

Saddle Processing

Tray Paper Sensor

PS201

Saddle Inlet Sensor

PS205

Saddle Switching

Lever HP Sensor

M202

Saddle Switching

Lever Motor

M207

Saddle

Delivery Motor

M204

Saddle Paper

Pushing Plate/

Folding Motor

PS211

Saddle Delivery

Motor Clock Sensor

PS212

Saddle Paper Pushing

Plate/Folding

Motor Clock Sensor

PCB201

Saddle Stitcher Controller PCB

Saddle Stitcher Unit

General Circuit Diagram

219

Содержание Staple Finisher-AA1

Страница 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Страница 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Страница 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Страница 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Страница 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Страница 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Страница 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Страница 178: ...A B Feed Direction Stapling Position Fixing Screw A B Stitcher Unit Fixing Screw Fixing Screw Mark 5 Adjustment 170 ...

Страница 184: ... Adjsting Phase Angle of the Paddle Unit 1 Put off the belt 1 1 2 Lower the swing roller till its end 5 Adjustment 176 ...

Страница 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Страница 204: ...4 5 6 7 8 9 7 Installation 196 ...

Страница 205: ...10 7 Installation 197 ...

Страница 210: ...11 NOTE Keep the parts as illustration above Installation of Buffer Pass Unit 1 7 Installation 202 ...

Страница 223: ...2 3 2x 7 Installation 215 ...

Страница 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...