Chapter 11

11-1

11.1 Scanning System

11.1.1 Procedure after Replacing the CIS (iR2020/

iR2020J/iR2016/iR2016J)

0011-2391

iR2016J / iR2016 / iR2020 /

After replacing the contact image sensor (CIS), go through the following

steps to perform inter-channel output correction:

1) Enter the service mode.

Sequentially press the User Mode key "

", 2 key, 8 key, and User Mode

key "

" on the operation panel.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 1 key.

After completion of the above steps, contact sensor output correction will be

performed and parameters will be set automatically.

11.1.2 Procedure after Replacing the CIS (iR2020i/

iR2016i)

0012-6059

iR2016i / iR2020i

After replacing the contact image sensor (CIS), go through the following

steps to perform inter-channel output correction:

1) Enter the service mode.

Sequentially press the Additional functions key, 2 key, 8 key, and Additional

functions key on the operation panel.

2) Press the arrow key on the touch panel to display "TEST MODE".

3) Press [OK].

4) Press the [2] key to display "SCAN TEST".

5) Press the [1] key to display "SHADING".

6) Press [OK].

After completion of the above procedure, the contact sensor output is com-

pensated and parameters are set automatically.

After completion of automatic adjustment, "OK" is displayed.

11.1.3 Procedure after Replacing the Copyboard Glass

(iR2020i/iR2016i)

0012-6055

iR2016i / iR2020i

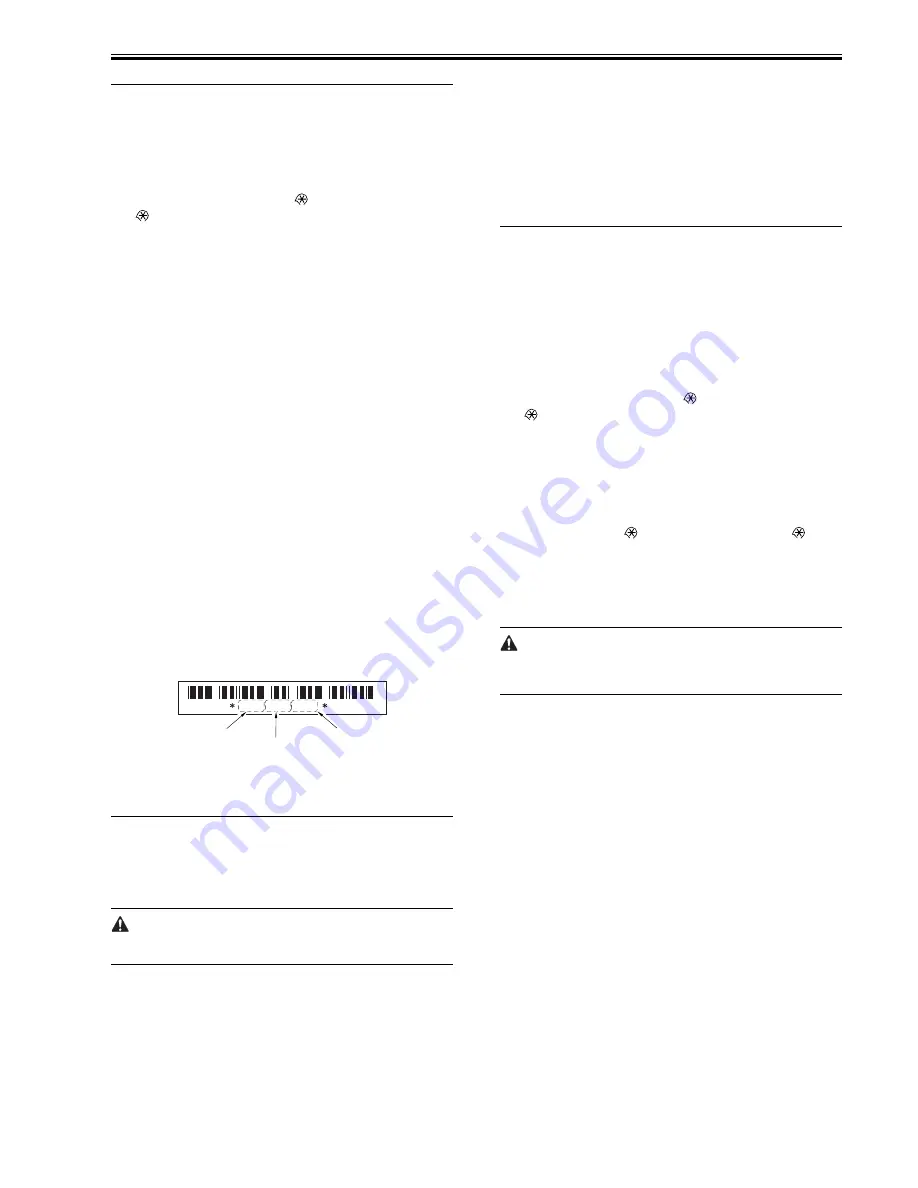

After replacing the copyboard glass, enter the correction values (X, Y, Z) of

the standard white plate which are indicated on the back of the new copy-

board glass in the service mode.

Correction value (X): Service mode>#SCAN>#SCAN NUMERIC>No.213

Correction value (Y): Service mode>#SCAN>#SCAN NUMERIC>No.214

Correction value (Z): Service mode>#SCAN>#SCAN NUMERIC>No.215

Also, rewrite the values on the service label.

F-11-1

11.2 Image Formation System

11.2.1 Procedure after Replacing the Developing

Assembly

0011-2545

iR2016J / iR2016 / iR2020 / / iR2016i / iR2020i

<Going through the Developer Idling Mode>

After replacing the developing assembly, go through the following steps

in the developing assembly idle rotation mode before installing the toner car-

tridge.

1) Plug the power cord into the outlet.

2) Open the front cover.

3) With the front cover open, turn on the main power switch.

4) When a message appears on the operation panel display, press the

following keys to enter the service mode:

Additional Functions key > 2 key > 8 key > Additional Functions key

5) Select "#PRINT" using the + or - key, and then press the OK key.

6) Select "#PRINT SW" using the + or - key, and hen press the OK key.

Confirm that the following message is displayed:

Message: #PRINT SW 001 00000000

7) Press the following keys and confirm the message:

# key > 1 key > 1 key

Message: #PRINT SW 011 00000000

8) Position the cursor to Bit-1 (second from right) using the + or - key, and

press the 1 key, and then confirm the following message:

Message: #PRINT SW 011 00000010

9) Press the OK key. Confirm that "SW 011" changes to "SW 012".

Message: #PRINT SW 012 00000000

10) Press the Reset key to exit the service mode.

11) Close the front cover. The machine will run in the developer idling mode

for about 1 minute.

12) When the machine stops, the idling mode ends.

Install, the toner cartridge following the above-mentioned procedure.

11.3 Electrical Components

11.3.1 Procedure after Replacing the Image Processor

PCB (iR2020/iR2020J/iR2016/iR2016J)

0011-2555

iR2016J / iR2016 / iR2020 /

If you have replaced the image processor PCB with a new one, perform the

following operations:

- Using the service support tool, download the latest firmware (System/

Boot).

- Input the all value printed on the service label affixed to the rear cover.

Make the following adjustments:

- Correction of output between CIS channels

1) Enter the service mode.

Sequentially press the User Mode key "

", 2 key, 8 key, and User Mode

key "

" on the operation panel.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 1 key.

After completion of the above steps, contact sensor output correction will be

performed and parameters will be set automatically.

- Read position adjustment (Stream reading: Only when the ADF is installed)

1) Enter the service mode.

Press the User Mode key "

", 2 key, 8 key, User Mode key "

" on the

operation panel of the host machine.

2) Using the arrow keys on the operation panel, display "TEST MODE".

3) Press the OK key.

4) Press the 2 key. "SCAN TEST" appears.

5) Press the 3 key. "SHEET POS ADJ" appears.

The optical system starts scanning. Several seconds later, automatic adjust-

ment of the reading position finishes and "OK" appears.

If automatic adjustment fails, "NG" appears. Perform the following pro-

cedure:

Clean the white roller of the DADF and the document glass of the host ma-

chine, and then retry auto adjustment.

11.3.2 Procedure after Replacing the Image Processor

PCB (iR2020i/iR2016i)

0012-6051

iR2016i / iR2020i

If you have replaced the image processor PCB with a new one, perform the

following operations:

- Using the service support tool, download the latest firmware (System/Boot)

and language files.

- Delete the languages not used at the destination (Service mode > CLEAR

> FILE SYSTEM).

- Input the all value printed on the service label affixed to the rear cover.

Make the following adjustments:

- Correction of output between CIS channels

1) Enter the service mode.

Sequentially press the Additional functions key, 2 key, 8 key, and Additional

functions key on the operation panel.

2) Press the arrow key on the touch panel to display "TEST MODE".

3) Press [OK].

4) Press the [2] key to display "SCAN TEST".

5) Press the [1] key to display "SHADING".

6) Press [OK].

After completion of the above procedure, the contact sensor output is com-

pensated and parameters are set automatically.

After completion of automatic adjustment, "OK" is displayed.

- Read position adjustment (Stream reading: Only when the ADF is installed)

1) Enter the service mode.

Sequentially press the Additional functions key, 2 key, 8 key, and Additional

functions key on the operation panel.

2) Press the arrow key on the touch panel to display "TEST MODE".

3) Press [OK].

4) Press the [2] key to display "SCAN TEST".

5) Press the [3] key to display "SHEET POS ADJ".

6) Press [OK].

The optical system starts scanning. Several seconds later, automatic adjust-

8 2 0 6 8 6 6 7 9 3 4 9

c o r r e c t o n

va l u e ( X )

c o r r e c t o n

va l u e ( Y )

c o r r e c t o n

va l u e ( Z )

Содержание iR2016 Series

Страница 2: ...Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...

Страница 6: ...Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...

Страница 22: ...Contents Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...

Страница 23: ...Chapter 1 Introduction Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...

Страница 24: ...Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...

Страница 43: ...Chapter 1 1 17 8 Pickup roller 17 Fixing film unit 9 Feed roller 18 Delivery roller ...

Страница 70: ...Chapter 1 1 44 ...

Страница 71: ...Chapter 2 Installation ...

Страница 72: ......

Страница 74: ......

Страница 120: ...Chapter 2 2 46 ...

Страница 121: ...Chapter 3 Main Controller ...

Страница 122: ......

Страница 124: ......

Страница 137: ...Chapter 4 Original Exposure System ...

Страница 138: ......

Страница 171: ...Chapter 5 Laser Exposure ...

Страница 172: ......

Страница 174: ......

Страница 182: ......

Страница 183: ...Chapter 6 Image Formation ...

Страница 184: ......

Страница 186: ......

Страница 197: ...Chapter 7 Pickup Feeding System ...

Страница 198: ......

Страница 218: ......

Страница 219: ...Chapter 8 Fixing System ...

Страница 220: ......

Страница 222: ......

Страница 244: ......

Страница 245: ...Chapter 9 External and Controls ...

Страница 246: ......

Страница 270: ......

Страница 271: ...Chapter 10 Maintenance and Inspection ...

Страница 272: ......

Страница 274: ......

Страница 277: ...Chapter 11 Standards and Adjustments ...

Страница 278: ......

Страница 280: ......

Страница 283: ...Chapter 11 11 3 ...

Страница 284: ......

Страница 285: ...Chapter 12 Correcting Faulty Images ...

Страница 286: ......

Страница 288: ......

Страница 297: ...Chapter 12 12 9 F 12 11 F 12 12 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 ...

Страница 298: ......

Страница 299: ...Chapter 13 Self Diagnosis ...

Страница 300: ......

Страница 302: ......

Страница 313: ...Chapter 14 Service Mode ...

Страница 314: ......

Страница 375: ...Chapter 15 Upgrading ...

Страница 376: ......

Страница 378: ......

Страница 398: ......

Страница 399: ...Chapter 16 Service Tools ...

Страница 400: ......

Страница 401: ...Contents Contents 16 1 Service Tools 16 1 16 1 1 Special Tools 16 1 16 1 2 Oils and Solvents 16 1 ...

Страница 402: ......

Страница 404: ......

Страница 405: ...Jan 30 2006 ...

Страница 406: ...Download Free Service Manual And Resetter Printer at http printer1 blogspot com ...