Chapter 2

2-51

2.7.3 Alarm Code

0011-7388

T-2-15

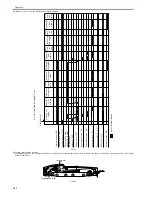

2.8 Power Supply

2.8.1 Overview

0011-2426

The following is a diagram of the machine's power supply system:

The machine is supplied with 24V and 13V power by its host machine. The 24V power is supplied to various loads by way of a circuit breaker (CB1). Of the 24V

power supplied to the loads, 24U is sent by way of a fuse, while 24R is sent directly.

The 13 V power is converted into 5 V for sensors by a regulator IC (IC15). Another regulator IC (IC26) is used to convert 5 V into 3.3 V, which is used to drive

the ADF controller PCB.

0080

image lead edge output timing

fault

S2,S3,SW301

At time of stream reading, the image lead edge signal is generated during acceleration over the distance

from standby position to image lead edge position.

0081

reversal speed setting fault

PI5

The speed setting of the reversal motor is the minimum speed (100 mm/sec) or lower or is the maximum

speed (700 mm/sec) or higher.

0082

reversal speed switchover fault

PI5

At time of a reversal motor speed switchover, the motor is not operating at a specific speed.

0083

reversal status fault

PI5

At time of a switchover of the motor state (acceleration, constant, deceleration), the motor is not in any

of the 3 settings.

0084

last original error

PI1

While the last original is being discharged from the platen roller or is being moved, a belt motor error

has occurred.

0085

error

PI1,PI2,

PI11

A motor error other than an IPC communication/pickup error has occurred. (less than 3 occurrences)

0090

ADF open

PI10

An ADF open condition has been detected.

0091

user DF open

PI10

An ADF open condition has been detected while the machine is in operation.

0092

cover open

PI3,PI6

A cover open condition (front or rear) has been detected.

0093

user cover open

PI3,PI6

While the machine is operating, a sensor in the paper path has detected an original.

0094

initial stationary

PI4,PI12,PI13,S

1,S2,S3,S4,S5,S

9

At the start of operation, the presence of an original has been detected by a senser in the paper path.

0095

cycle NG

S6

While no sensor is on, the pickup signal is received for a specific time (2 sec).

0096

residual original

S1

Before the start of a left pickup job, the reversal sensor has detected an original while the belt motor is

being driven for a specific time.

0097

manual feeder residual original

S1,S9

At time of manual feed pickup, the reversal sensor detects an original while the manual feeder

registration roller sensor also detects an original.

0098

power-down

-

While the machine is operating, a drop has occurred in the voltage of the power supplied by the host

machine.

Code

Name

Description

03

separation fault

a jam caused by the 1st original not

reaching the post-separation sensor

a jam caused by the 1st original not

reaching the registration sensor

11

decrease in number of originals

after jam recovery

a condition caused by a decrease in the number of originals in the tray

before delivery of as many as [originals to be recovered - 1] have been

delivered at time of jam

recovery

21

mode fault

selection of mode not permitting

execution

Code

Sensor type

Sensor

notation

Description

Содержание DADF-Q1

Страница 1: ...Aug 24 2007 Service Manual Feeder DADF Q1 ...

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 Specifications ...

Страница 12: ......

Страница 14: ......

Страница 18: ......

Страница 19: ...Chapter 2 Functions ...

Страница 20: ......

Страница 22: ......

Страница 75: ...Chapter 3 Parts Replacement Procedure ...

Страница 76: ......

Страница 107: ...Chapter 4 Maintenance ...

Страница 108: ......

Страница 149: ...Chapter 5 Error Code ...

Страница 150: ......

Страница 151: ...Contents Contents 5 1 Service Error Code 5 1 5 1 1 E402 5 1 5 1 2 E404 5 1 5 1 3 E405 5 1 5 1 4 E410 5 1 5 1 5 E420 5 1 ...

Страница 152: ......

Страница 154: ......

Страница 155: ...Aug 24 2007 ...

Страница 156: ......