Chapter 4

4-21

A single press on each switch will shift the original stop position by 0.5

mm.

When the correct position is attained (after switch operation), press the

push switch SW2.

- The original will be delivered, and the new setting will be stored in

memory.

F-4-105

T-4-8

F-4-106

Holding down the push switch will not cause more than a single shift.

EX

If the copy paper stops 12 mm from the copyboard glass,

Close the DADF slowly leaving the copy paper on the copyboard glass.

To shift the stop position 1 mm to the left, the following is true:

1 0.5 (adjustment interval) = 2

Hence, press the push switch SW4 twice, and press the push switch SW2.

- The copy paper will be delivered, and new setting will be stored in memory.

4.3.1.7 Stream Reading Speed Adjustment

0013-3708

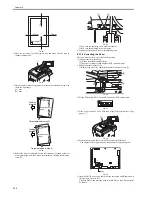

1) Place the test chart in the original pickup tray, and make a copy at a 100%

reproduction ratio.

2) Put the copy and chart together, and compare the length of the image

in feed direction, making sure that dimension a is as indicated. If not, go

to the next step.

standard: a </= 1 mm

F-4-107

3) Make the following selections: FEEDER>ADJUST>LA-SPEED; then,

change the setting to make adjustments.

-To make the image on the copy longer, decrease the setting (so that the

stream reading speed will be decreased).

-To make the image on the copy shorter, increase the setting (so that the

stream reading speed will be increased).

[ range -30 to 30 : -3 to + 3 % ]

4.3.2 Adjustment at Time of Parts Replacement

4.3.2.1 Outline

0011-3496

T-4-9

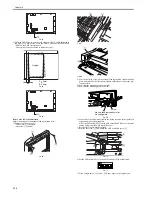

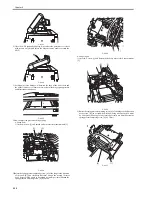

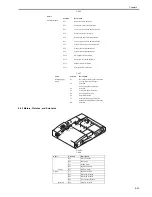

4.3.2.2 Replacing the EEPROM

0011-3499

Perform the following when replacing the ADF controller PCB.

1) Remove the EEPROM (IC8) from the faulty ADF controller PCB.

Switch

Direction of shift

SW3

Right

SW4

Left

J1

J2

J5

J3

J6

J7

J8

J9

J10

J16

J15

J11

J14

IC8

J13

J12

J4

CB1

SW1

DSP1

SW4SW3SW2

Original

SW3

SW4

Major parts

Work

- ADF controller PCB

1) Replacement of the

EEPROM

-EEPROM (memory back-up)

2) Adjust the sensors and the

delivery motor

-Reversal sensor (S1)

-Pre-registration roller paper sensor (S2)

-Post-registration roller paper sensor (S3)

-Separation paper sensor (S4)

-Skew paper sensor (S5)

-Original sensor (S6)

-Original trailing edge sensor (S7)

-Manual feed registration roller paper sensor (S9)

-Delivery motor (M5)

a

a

<If Shorter on Chart>

<If Longer on Chart>

Содержание DADF-Q1

Страница 1: ...Aug 24 2007 Service Manual Feeder DADF Q1 ...

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 Specifications ...

Страница 12: ......

Страница 14: ......

Страница 18: ......

Страница 19: ...Chapter 2 Functions ...

Страница 20: ......

Страница 22: ......

Страница 75: ...Chapter 3 Parts Replacement Procedure ...

Страница 76: ......

Страница 107: ...Chapter 4 Maintenance ...

Страница 108: ......

Страница 149: ...Chapter 5 Error Code ...

Страница 150: ......

Страница 151: ...Contents Contents 5 1 Service Error Code 5 1 5 1 1 E402 5 1 5 1 2 E404 5 1 5 1 3 E405 5 1 5 1 4 E410 5 1 5 1 5 E420 5 1 ...

Страница 152: ......

Страница 154: ......

Страница 155: ...Aug 24 2007 ...

Страница 156: ......