12

12

4

Error Messages

4.1

Error Messages of the Printer

For detailed information about printer errors (e.g. 'Paper out', 'Ribbon out', etc.)

Check the operator's manual of the

printer.

Error treatment:

Clearing the error results.

Press the

to synchronize the label feed, remove the left over labels manually.

To quit the error state press

Repeat

.

After error correction, the label causing the error will be reprinted.

4.2

Error messages of the applicator

The following table contains an overview of error messages and their possible causes. It also suggests methods to

resolve the problem :

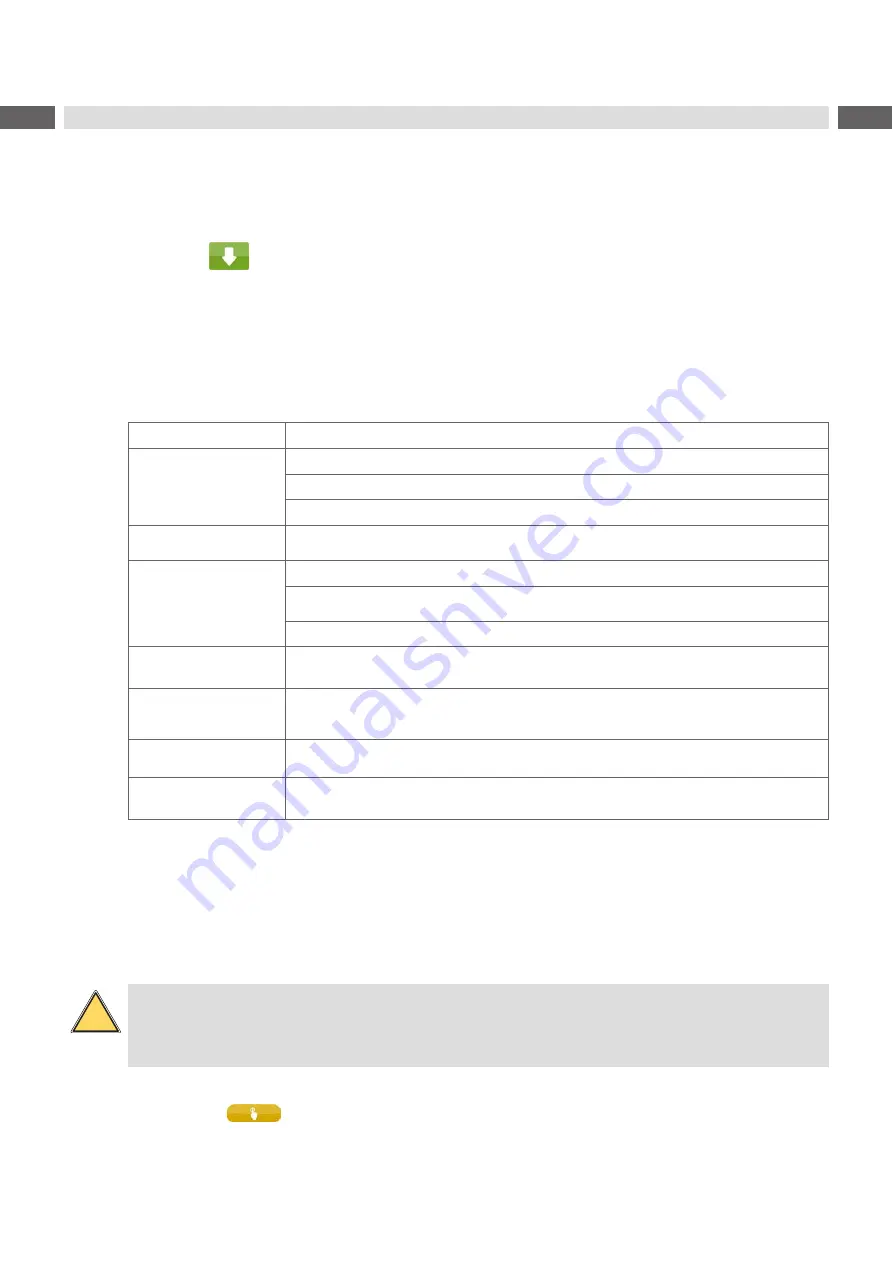

Error Message

Possible Cause

Air pressure error

Compressed air is switched off

Pressure to low < 4 bar

Pressure to high > 6 bar

Label not depos.

Label has not been placed onto the product; after the pad has moved back the label still

sticks on the pad

Upper position not reached

Pad is not in start position if the printer swiched on

Pad has not reached the home position within 2s after the movement of the pad was started

Pad has undefined leaving the start position

External error

Process of labeling was braked via the I/O interface of the printer with the XSTP signal

Upper position not left

There has been no change of the switch state at the upper sensor at the cylinder

between the start of the labelling process and the signal from the labelling position

sensor

Vac. plate empty

Label has not been picked up properly by the pad; or label fell off the pad before it could

be placed onto the product

Lower position not reached

Pad has not reached the starting position within 2s after the pad has left the labelling

position; or pad has left the starting position unauthorized

Table 2

Error messages of the applicator

Error treatment:

Clear the error state.

In order to clear the error state press

continue, repeat

or

cancel.

Continue

with the next label in the printing queue.

Repeat

repeat the print of the label causing the error.

Only applicable with error

Vac. plate empty.

Cancel

the current print job.

!

Warning!

After the error has been resolved the pad will immediately move back to the starting position!

Danger of injury to hands and fingers by the moving pad!

Do not reach into the area of the moving pad and keep long hair, loose clothes, and jewelry away.

Reprinting a label, interrupted by an error, is not possible without a new printing job.

In the mode "apply/print" before the standard cyclic operation can commence the signal "print first label" must be

sent or push

to send a printed label to the pad.

Содержание 4414 Series

Страница 1: ...Service Manual 4414 MADE IN GERMANY Stroke Applicator...

Страница 36: ...36 36 9 Drawings 9 2 Pneumatic drawing Type 4414 Fig 40 Pneumatics Type 4414...

Страница 37: ...37 9 Drawings 9 3 Label position Type 4414 L Fig 41 Label position 4414L...

Страница 38: ...38 38 9 Drawings 9 4 Label position Type 4414 R Fig 42 Label position 4414R...