2007 Buell Ulysses: Electrical

7-33

HOME

CLEANING AND INSPECTION

CAUTION

Do not strike or drop alternator rotor or damage to mag-

net adhesive may occur. Magnet adhesive damage can

result in rotor failure.

1.

Clean rotor with a petroleum-base solvent. Remove all

foreign material from rotor magnets. Replace rotor if rotor

magnets are cracked or loose.

2.

Clean stator by wiping with a clean cloth.

3.

Examine stator leads for cracked or damaged insulation.

NOTE

The rotor and stator can be replaced individually if either is

damaged.

ASSEMBLY/INSTALLATION

Depending on whether the rotor, the stator, or both the rotor

and stator were removed/disassembled, perform the applica-

ble procedures which follow:

1.

See

Figure 7-34.

Feed stator wiring (4) with attached

grommet (3) into open grommet hole in left crankcase

half.

2.

Apply a light coating of clean engine oil or chaincase

lubricant to grommet. Install grommet into hole in left

crankcase half.

NOTE

Stator TORX screws contain a thread locking compound. Do

not reuse existing screws. Always use new screws with the

proper thread locking compound. Loss of torque on TORX

fasteners could result in alternator damage.

3.

Position stator (2) on left crankcase half. Secure stator

using four

new

TORX screws (1). Tighten TORX screws

to 30-40

in-lbs

(3-4 Nm).

4.

Install retainer plate with

new

fasteners and tighten to 56

in-lbs

(6.3Nm).

5.

See

Figure 7-34.

Route stator wiring (4) behind rear cyl-

inder and in front of transmission breather hose.

a. Route stator wire (4) between The vent oil line and

the return oil line.

b. Install connector (5) [46] onto the stator wiring (4)

using cavities 1, 2, 3 of connector (5) [446]. See

B.2

DEUTSCH ELECTRICAL CONNECTORS

for addi-

tional information.

NOTE

See

7.26 SPROCKET COVER WIRING

for remaining wire

routing information.

6.

See

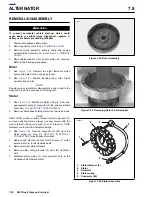

Figure 7-35.

Attach rotor to sprocket.

a. Position rotor (3) on sprocket (1). Align holes in

sprocket with holes in rotor.

b. Insert

eight

new

mounting fasteners through rotor

and start fasteners into tapped holes in sprocket.

c.

Position a section of pipe (2) with an inside diameter

larger than the sprocket mounting hub over center of

rotor. Press rotor onto sprocket. Tighten fasteners to

120-140

in-lbs

(13.5-15.8 Nm).

7.

Install clutch assembly, primary chain and engine

sprocket/rotor assembly as a unit. See

6.5 PRIMARY

CHAIN

.

8.

Install primary cover. See

6.2 PRIMARY COVER

.

9.

Connect negative battery cable.

10. Test charging system. See

7.7 CHARGING SYSTEM.

Figure 7-35. Pressing Rotor onto Sprocket

3560

1.

Sprocket

2.

Pipe section

3.

Rotor

1

3

2

Содержание 2007 ULYSSES

Страница 17: ...A 16 2007 Buell Ulysses Appendix A HOME NOTES ...

Страница 35: ...B 18 2007 Buell Ulysses Electrical HOME 2007 Ulysses Model Main Harness 2007 Ulysses Model Main Harness ...

Страница 51: ...D 2 2007 Buell Ulysses Appendix D HOME Figure D 2 Rear Brake Systems Top View b1115acsxu ...

Страница 52: ...2007 Buell Ulysses Appendix D D 3 HOME Figure D 3 Rear Brake Systems Left Side View b1116adsxu ...

Страница 63: ...D 14 2007 Buell Ulysses Appendix D HOME NOTES ...

Страница 73: ......

Страница 103: ...1 30 2007 Buell Ulysses Maintenance HOME NOTES ...

Страница 129: ......

Страница 237: ...2 108 2007 Buell Ulysses Chassis HOME NOTES ...

Страница 239: ......

Страница 309: ...3 70 2007 Buell Ulysses Engine HOME NOTES ...

Страница 347: ...3 108 2007 Buell Ulysses Engine HOME NOTES ...

Страница 351: ...4 2 2007 Buell Ulysses Fuel System HOME Upper tie bar 25 27 ft lbs 33 9 36 6 Nm page 4 102 ITEM TORQUE NOTES ...

Страница 391: ...4 42 2007 Buell Ulysses Fuel System HOME NOTES ...

Страница 481: ......

Страница 505: ......

Страница 561: ...6 56 2007 Buell Ulysses Drive Transmission HOME NOTES ...

Страница 563: ......

Страница 587: ...7 24 2007 Buell Ulysses Electrical HOME NOTES ...

Страница 645: ...7 82 2007 Buell Ulysses Electrical HOME NOTES ...

Страница 647: ......