51

The W7220 calculates the enthalpy and dew point using the OA

temperature and humidity input from the OA enthalpy sensor.

When the OA temperature, OA humidity and OA dew point are

all below the selected boundary, the economizer sets the econo

-

mizing mode to YES, economizing is available.

When all of the OA conditions are above the selected boundary,

the conditions are not good to economize and the mode is set to

NO.

Figure 72 shows the 5 current boundaries. There is also a high

limit boundary for differential enthalpy. The high limit bound

-

ary is ES1 when there are no stages of mechanical cooling en

-

ergized and HL (high limit) when a compressor stage is

energized.

TWO-SPEED FAN OPERATION

NOTE: Two-Speed Fan operation applies to size 07 models only.

The W7220 controller has the capability to work with a system us

-

ing a 2-speed supply fan. The W7220 does not control the supply

directly but uses the following input status to determine the speed

of the supply fan and controls the OA damper to the required posi

-

tion, see Table 28.

The W (heating mode) is not controlled by the W7220 but it re

-

quires the status to know where to position the OA damper for

minimum position for the fan speed.

The 2 speed fan delay is available when the system is programmed

for 2 speed fan (in the System Setup menu item). The 2 speed fan

delay is defaulted to 5 minutes and can be changed in the Ad

-

vanced Setup menu item. When the unit has a call for Y1 In and in

the free cooling mode and there is a call for Y2 In, the 2-speed fan

delay starts and the OA damper will modulate 100% open, the

supply fan should be set to high speed by the unit controller.

After the delay one of two actions will happen:

• The Y2 In call will be satisfied with the damper 100%

open and fan on high speed and the call will turn off

OR

• If the call for additional cooling in the space has not been

satisfied then the first stage of mechanical cooling will be

enabled through Y1 Out or Y2 Out.

CHECKOUT

Inspect all wiring connections at the economizer module’s termi

-

nals, and verify compliance with the installation wiring diagrams.

For checkout, review the Status of each configured parameter and

perform the Checkout tests.

NOTE: For information about menu navigation and use of the

keypad, see Interface Overview on page 41.

Power Up

After the W7220 module is mounted and wired, apply power.

Initial Menu Display

On initial start up, Honeywell displays on the first line and econo

-

mizer W7220 on the second line. After a brief pause, the revision

of the software appears on the first line and the second line will be

blank.

Power Loss (Outage or Brownout)

All set points and advanced settings are restored after any power

loss or interruption.

NOTE: All settings are stored in non-volatile flash memory.

Status

Use the Status menu (see Table 17) to check the parameter values

for the various devices and sensors configured.

NOTE: For information about menu navigation and use of the

keypad, see Interface Overview on page 41.

Checkout Tests

Use the Checkout menu (see page 46) to test the damper operation

and any configured outputs. Only items that are configured are

shown in the Checkout menu.

NOTE: For information about menu navigation and use of the

keypad, see Interface Overview on page 41.

To perform a Checkout test:

1. Scroll to the desired test in the Checkout menu using the ▲

and ▼ buttons.

2. Press the

(Enter) button to select the item. RUN?

appears.

3. Press the

(Enter) button to start the test. The unit pauses

and then displays IN PROGRESS. When the test is complete,

DONE appears.

4. When all desired parameters have been tested, press the

(Menu Up) button to end the test.

The Checkout tests can all be performed at the time of installation

or at any time during the operation of the system as a test that the

system is operable.

TROUBLESHOOTING

Alarms

The economizer module provides alarm messages that display on

the 2-line LCD.

NOTE: Upon power up, the module waits 60 minutes before

checking for alarms. This allows time for all the configured

Table 27 — Single Enthalpy and Dual Enthalpy High Limit Curves

ENTHALPY

CURVE

TEMP. DRY

BULB (F)

TEMP.

DEWPOINT (F)

ENTHALPY

(btu/lb/da)

POINT P1

POINT P2

TEMP. (F)

HUMIDITY

(%RH)

TEMP. (F)

HUMIDITY

(%RH)

ES1

80

60

28.0

80

36.8

66.3

80.1

ES2

75

57

26.0

75

39.6

63.3

80.0

ES3

70

54

24.0

70

42.3

59.7

81.4

ES4

65

51

22.0

65

44.8

55.7

84.2

ES5

60

48

20.0

60

46.9

51.3

88.5

HL

86

66

32.4

86

38.9

72.4

80.3

Table 28 — Fan Speed

STATE

FAN SPEED

OCC

Low

Y1

Low

Y2

High

W

High

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Be sure to allow enough time for compressor start-up and

shutdown between checkout tests so that you do not short-

cycle the compressors.

Содержание 547K

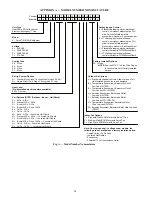

Страница 94: ...94 APPENDIX D WIRING DIAGRAMS Fig I 547K 04 06 Power Wiring Diagram 208 230 1 60 ...

Страница 95: ...95 APPENDIX D WIRING DIAGRAMS Fig J 547K 04 07 Power Wiring Diagram 208 230 3 60 ...

Страница 96: ...96 APPENDIX D WIRING DIAGRAMS Fig K 5047K 04 07 Power Wiring Diagram 460 575 3 60 ...