12

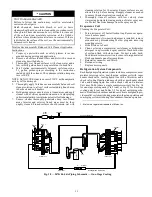

Fig. 19 — 547K 07N Piping Schematic — Two-Stage Cooling, Single Circuit

Evaporator Coil Metering Devices

Two different evaporator coil metering systems are used on

547K sizes 04-07. 547K 04-06A units use the Acutrol™

system for evaporator metering. 547K 07N units use a TXV-

distributer system.

Check the unit’s information data plate for Position 8 value,

then compare this value to the Model Number Nomenclature

on page 54 to confirm the unit’s construction.

The metering devices are multiple fixed-bore devices (Acutrol)

swedged into the horizontal outlet tubes from the liquid header,

located at the entrance to each evaporator coil circuit path.

These are non-adjustable. Service requires replacing the entire

liquid header assembly.

To check for possible blockage of one or more of these meter

-

ing devices, disconnect the supply fan contactor (IFC) coil,

then start the compressor and observe the frosting pattern on

the face of the evaporator coil. A frost pattern should develop

uniformly across the face of the coil starting at each horizontal

header tube. Failure to develop frost at an outlet tube can indi

-

cate a plugged or missing orifice.

THERMOSTATIC EXPANSION VALVE (TXV)

All 547K 07 units include TXV control. The TXV is a bi

-

flow,

bleed port expansion valve with an external equalizer. The

TXVs are specifically designed to operate with Puron

®

(R410A) refrigerant. Use only factory-authorized TXVs.

TXV Operation

The TXV is a metering device that is used in air conditioning

and heat pump systems to adjust to the changing load

conditions by maintaining a preset superheat temperature at the

outlet of the evaporator coil.

The volume of refrigerant metered through the valve seat is

dependent upon the following:

1. Superheat temperature is sensed by cap tube sensing bulb

on suction tube at outlet of evaporator coil. This tempera

-

ture is converted into pressure by refrigerant in the bulb

pushing downward on the diaphragm, which opens the

valve using the push rods.

2. The suction pressure at the outlet of the evaporator coil is

transferred through the external equalizer tube to the

underside of the diaphragm.

3. The pin is spring loaded, which exerts pressure on the

underside of the diaphragm. Therefore, the bulb pressure

works against the spring pressure and evaporator suction

pressure to open the valve. If the load increases, the tem

-

perature increases at the bulb, which increases the pressure

on the top side of the diaphragm. This opens the valve and

increases the flow of refrigerant. The increased refrigerant

flow causes the leaving evaporator temperature to

decrease. This lowers the pressure on the diaphragm and

B

Acutrol

DFT 1

Cooling Liquid Line

A

D

Outdoor Coil

Indoor Coil

C

Heating Mode Liquid Line

Strainer

Filter

Drier

LPS/LOC

Accurater

TXV

COMPRESSOR

ACCUMULATOR

HPS

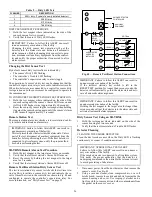

Table 3 — Cooling Mode (each circuit)

COMPONENT

STATUS/POSITION

Reversing Valve

Energized

Check Valve A

Closed

Check Valve B

Open

Check Valve C

Closed

Check Valve D

Open

Table 4 — Heating Mode (each circuit)

COMPONENT

STATUS/POSITION

Reversing Valve

De-energized

Check Valve A

Open

Check Valve B

Closed

Check Valve C

Open

Check Valve D

Closed

Table 5 — Defrost Mode

COMPONENT

STATUS/POSITION

Defrost Thermostat

Closed

Outdoor Fan(s)

Off

Reversing Valve

Energized

Check Valve A

Closed

Check Valve B

Open

Check Valve C

Closed

Check Valve D

Open

UNIT SIZE

EVAPORATOR METERING

04-06

Acutrol

07

TXV

Содержание 547K

Страница 94: ...94 APPENDIX D WIRING DIAGRAMS Fig I 547K 04 06 Power Wiring Diagram 208 230 1 60 ...

Страница 95: ...95 APPENDIX D WIRING DIAGRAMS Fig J 547K 04 07 Power Wiring Diagram 208 230 3 60 ...

Страница 96: ...96 APPENDIX D WIRING DIAGRAMS Fig K 5047K 04 07 Power Wiring Diagram 460 575 3 60 ...