20

NOTES:

1.

Jumper for 1-3 seconds: Factory Test — The defrost interval timing is reduced by a factor of 0.1 seconds/minute based on the positions of DIP

switches SW1 and SW2 (i.e., 90 minutes will be reduced to 9 seconds).

2.

Jumper for 5-20 seconds: Forced Defrost — Defrost runs for 30 seconds if DFT2 is open.

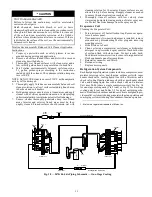

Reversing Valve Control

The DFB has two outputs for unit reversing valve control. Opera

-

tion of the reversing valves is based on internal logic; this applica

-

tion does not use an “O” or “B” signal to determine reversing

valve position. Reversing valves are energized during the cooling

stages and the defrost cycle and de-energized during heating cy

-

cles. Once energized at the start of a cooling stage, the reversing

valve will remain energized until the next heating cycle demand is

received. Once de-energized at the start of a Heating cycle, the re

-

versing valves will remain de-energized until the next cooling

stage is initiated.

Compressor Control

The DFB receives inputs indicating Stage 1 Cooling, Stage 2

Cooling and Stage 1 Heating from the space thermostat or unit

control system (RTU Open controller); it generates commands to

start compressors with or without reversing valve operation to pro

-

duce Stage 1 Cooling (one compressor runs), Stage 2 Cooling

(both compressors run) or Stage 1 Heating (both compressors run).

Auxiliary (Electric) Heat control

The 547K unit can be equipped with one or two auxiliary electric

heaters, to provide a second stage of heating. The DFB will ener

-

gize this Heating System for a Stage 2 Heating Command (heaters

operate concurrently with compressor(s) in the Stage 1 Heating

cycle), for an Emergency Heating sequence (compressors are off

and only the electric heaters are energized) and also during the De

-

frost cycle (to eliminate a “cold blow” condition in the space).

Defrost

The defrost control mode is a time/temperature sequence. There

are two time components: The continuous run period and the

test/defrost cycle period. The temperature component is provided

by Defrost Thermostat 1 and 2 (DFT1 and DFT2) mounted on the

outdoor coil.

The continuous run period is a fixed time period between the end

of the last defrost cycle (or start of the current Heating cycle)

during which no defrost will be permitted. This period can be set

at 30, 60, 90 or 120 minutes by changing the positions of DIP

switches SW1 and SW2 (see Fig. 33 and Table 8). The default run

period is 30 minutes.

Shorting the jumpers for a period of 5 to 20 seconds bypasses the

remaining continuous run period and places the unit in a Forced

Defrost mode. If the controlling DFT is closed when this mode is

initiated, the unit will complete a normal defrost period that will

terminate when the controlling DFT opens or the 10 minute de

-

frost cycle limit is reached. If the controlling DFT is open when

this mode is initiated, the Defrost cycle will run for 30 seconds.

Both modes end at the end of the Defrost cycle.

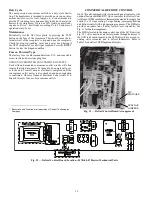

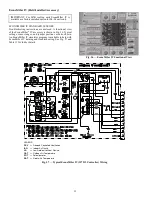

Fig. 33 — DIP Switch Settings - Defrost Board

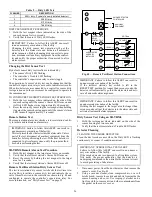

Table 7 — 547K Defrost Board I/O and Jumper Configurations

POINT NAME

TYPE OF I/O

CONNECTION PIN NUMBER

UNIT CONNECTION

NOTE

INPUTS

G Fan

DI, 24 vac

P2-3

CTB-G

Y1 Cool 1

DI, 24 vac

P2-5

CTB-Y1

Y2 Cool 2

DI, 24 vac

P2-4

CTB-Y2

W1 Heat 1

DI, 24 vac

P2-7

CTB-W1

W2 Heat 2

DI, 24 vac

P2-6

CTB-W2

R Power

24 vac

P3-1

CONTL BRD-8

C Common

24 vac

P3-2

CONTL BRD-4

DFT 1

DI, 24 vac

DFT-1 to DFT-1

—

DFT 2

DI, 24 vac

DFT-2 to DFT-2

—

OUTPUTS

IFO Fan On

DO, 24 vac

P3-9

REHEAT/HP-2

OF OD Fan On

DO, 24 vac

OF

OFR

RVS1

DO, 24 vac

P3-7 to P3-5

—

Energize in COOL

RVS2

DO, 24 vac

P3-6 to P3-4

—

Energize in COOL

COMP 1

DO, 24 vac

P3-10

FPT1-REHEAT/HP-6

COMP2

DO, 24 vac

P3-8

FPT2-REHEAT/HP-8

HEAT 2

DO, 24 vac

E-HEAT

TB4-1

COM

24 vac

P3-3

TB4-3

CONFIGURATION

Select Jumper

24 vac

P1-1

—

SPEED-UP CONFIGURATION

Speed-Up Jumper

—

JMP17

—

Speed-Up Jumper

—

JMP18

—

Table 8 — DIP Switch Positions

1

2

1

2

1

2

1

2

3

1

•

1

•

1

1

•

•

1

•

On

0

•

0

•

0

•

•

0

0

Off

30 minutes

(factory default)

60 minutes

90 minutes

120 minutes

Fan Delay

Содержание 547K

Страница 94: ...94 APPENDIX D WIRING DIAGRAMS Fig I 547K 04 06 Power Wiring Diagram 208 230 1 60 ...

Страница 95: ...95 APPENDIX D WIRING DIAGRAMS Fig J 547K 04 07 Power Wiring Diagram 208 230 3 60 ...

Страница 96: ...96 APPENDIX D WIRING DIAGRAMS Fig K 5047K 04 07 Power Wiring Diagram 460 575 3 60 ...