16

1. On a new installation, air entrapped in oil line leading from

tank to nozzle must be thoroughly purged in order to

prevent excessive after drip. The oil pump is provided with

a special fitting which allows purging of any air between

tank and oil pump. The proper procedure for performing

this operation is as follows:

a. Place a piece of clear plastic 1/4--in. (6 mm) diameter

tubing over purge fitting on oil pump.

b. Start oil burner, then open purge fitting and allow burn-

er to run until purge tube is completely free of air

bubbles.

c. Tighten purge fitting. Allow oil to run to nozzle and

fire burner.

d. If purging takes longer than 15 sec. and no flame has

been established, burner stops. Push reset button on

front of primary control to restart burner.

e. For detailed information on operation of primary con-

trol, refer to burner instructions included with furnace.

2. The oil pressure regulator is factory set to give oil pressure

of 135 psig for the model having 105,000 BTUH input and

130 psig for the model having 119,000 BTUH input. The

firing rate noted on nameplate may be obtained using the

nozzles and pump pressures indicated in Table 6. The prop-

er oil burner turbulator setting for all the firing rates is 0

(zero).

3. A test kit to measure smoke, stack draft, over--fire draft,

CO2, oil--pump pressure, and stack temperatures MUST be

used in order to obtain proper air band setting.

4. The proper smoke number has been established by

engineering tests to be between 0 and 1. This degree of

smoke emission is commonly referred to as a “trace” of

smoke. It is recommended to use a Bacharach true--spot

smoke test set or equivalent.

a. Pierce a test hole in the flue pipe, approximately 18 in

(457 mm) from the furnace breech.

b. Insert the smoke test probe into the hole. For installation

using sidewall venting, use the orifice provided on the

breech plate.

c. From a cold start, let the unit operate for 5 minutes.

d. Adjust the burner air setting to achieve between 0 and 1

on the Bacharach Scale(or a trace);

e. Take a CO2 sample at the same test location where the

#1 smoke reading was taken and make note of it.

Example: 13.8% of CO2 or 2.5% of O2.

f. Adjust the burner air setting to obtain a: -- CO2 reading

1.5% lower or -- a O2 reading 2.0% higher than the

reading associated with the #1 smoke.

Example: 12.3% of CO2 or 4.5% of O2;

g. This method of adjusting the burner will result in clean

combustion (Smoke reading from the Bacharach scale

between 0 and a trace) and ensure the proper

functioning of the system.

5. In order to ensure proper draft through furnace, a barometric

draft regulator (supplied with furnace) must be installed.

In order for this device to function properly, barometric damper

must be mounted with hinge pins horizontal and face of damper

vertical. (See instructions included with damper.) The draft

regulator should be adjusted after furnace has been firing for at

least 5 min., and set between --0.025 and --0.035 in. wc. (See Table

5.)

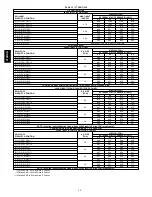

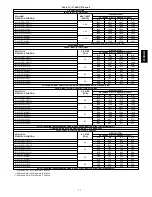

Table 5 – Furnace Draft Conditions (in wc)

FURNACE

INPUT

(BTUH)

FLUE DRAFT

MINIMUM

OVER---FIRE DRAFT

MAXIMUM

TOTAL

RESTRICTION

THROUGH HEAT

EXCHANGER

70,000

---0.025

0.010

0.020 to 0.035

91,000

---0.025

0.020

0.030 to 0.045

105,000

---0.025

0.025

0.035 to 0.050

119,000

---0.025

0.025

0.035 to 0.050

140,000

---0.025

0.025

0.035 to 0.050

154,000

---0.025

0.025

0.035 to 0.050

6. The over--fire draft, which is taken through observation

door (located in center line above burner in front panel of

furnace), is a measurement necessary to determine if there is

a blockage between oil burner and flue outlet.

There should be a total pressure drop of between 0.020 and

0.05 in. wc. through furnace as shown in Table 5. The over--

fire draft must be set within the range shown in Table 5.

A reading outside the range shown in Table 5 (for example

+0.1 in. wc.) would indicate that furnace is in an extremely

high--pressure condition in primary section. This condition

may be caused by any of the following problems:

a. Excessive combustion air due to air band being too

wide open.

b. A lack of flue draft (chimney effect) or some other

blockage, such as soot, in secondary section of heat

exchanger.

c. Use of an oversized nozzle input.

d. Pump pressure over the values listed in Table 6.

7. After having adjusted the burner combustion, insert a ther-

mometer into the test hole in the breech pipe. The vent tem-

perature should be between 400 and 535

_

F (204 and 302

_

C). If not, check for improper air temperature rise, pump

pressure, nozzle size or a badly soiled heat exchanger.

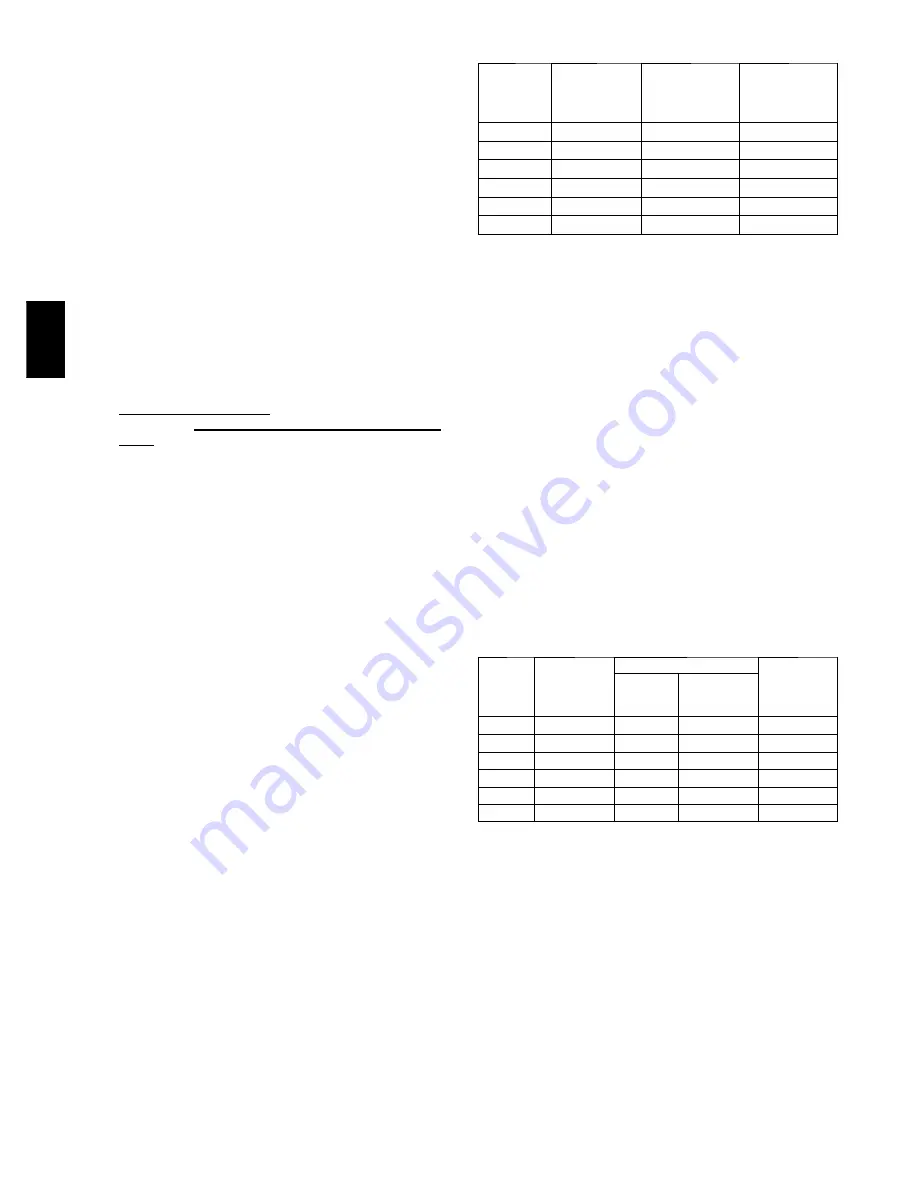

Table 6 – Burner Input and Nozzle Size

FURNACE

INPUT

(BTUH)

FIRING RATE

GAL/HR (US)*

RIELLO OIL BURNER

PUMP

PRESSURE

(PSIG)

NO. 40

SERIES

MODEL

DELAVAN

NOZZLE

70,000

0.50

F3

0.40 -- 70A

160

91,000

0.65

F3

0.50 -- 70W

170

105,000

0.75

F3

0.65 -- 70W

135

119,000

0.85

F5

0.75 -- 70B

130

140,000

1.00

F5

0.85 -- 70W

140

154,000

1.10

F5

1.00 -- 70W

125

* For rating purposes only.

Additional information on the operation and adjustment of burner

can be found in the burner manual, included with the furnace.

After all the setup procedures mentioned above have been

completed, the burner should be allowed to operate and an

inspection mirror should be used to observe the flame pattern at tip

of nozzle. Any irregularities such as burning to 1 side or pulsating

flame patterns should be corrected by changing nozzle.

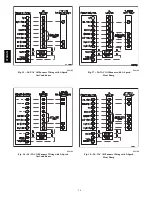

Step 4 — Fan Adjustment Check

This furnace is equipped with a variable--speed motor. The blower

is factory set to deliver the required airflow for 0.75GAL/HR(US)

INPUT and 3.0 tons air conditioning for the 374RAN105 (See

Tables 7, 8, and 9 and Fig. 19.). The blower is factory set to deliver

the required airflow for 0.85GAL/HR (US) INPUT and 5 tons air

conditioning for the 374RAN120. (See Tables 10, 11 and 12 and

Fig. 19.) The blower is field adjustable to deliver the required

airflow for other capacities.

374RAN