5

space, the number of windows and ventilation openings, the

number of doors to the outside, internal doors which can close off

unconfined space, and overall tightness of building construction.

Consideration must also be given to the amount of storage items

(furniture, boxes, etc.) within the unconfined space which take

away from the air volume. (Refer to Table 2.)

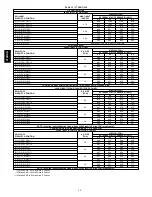

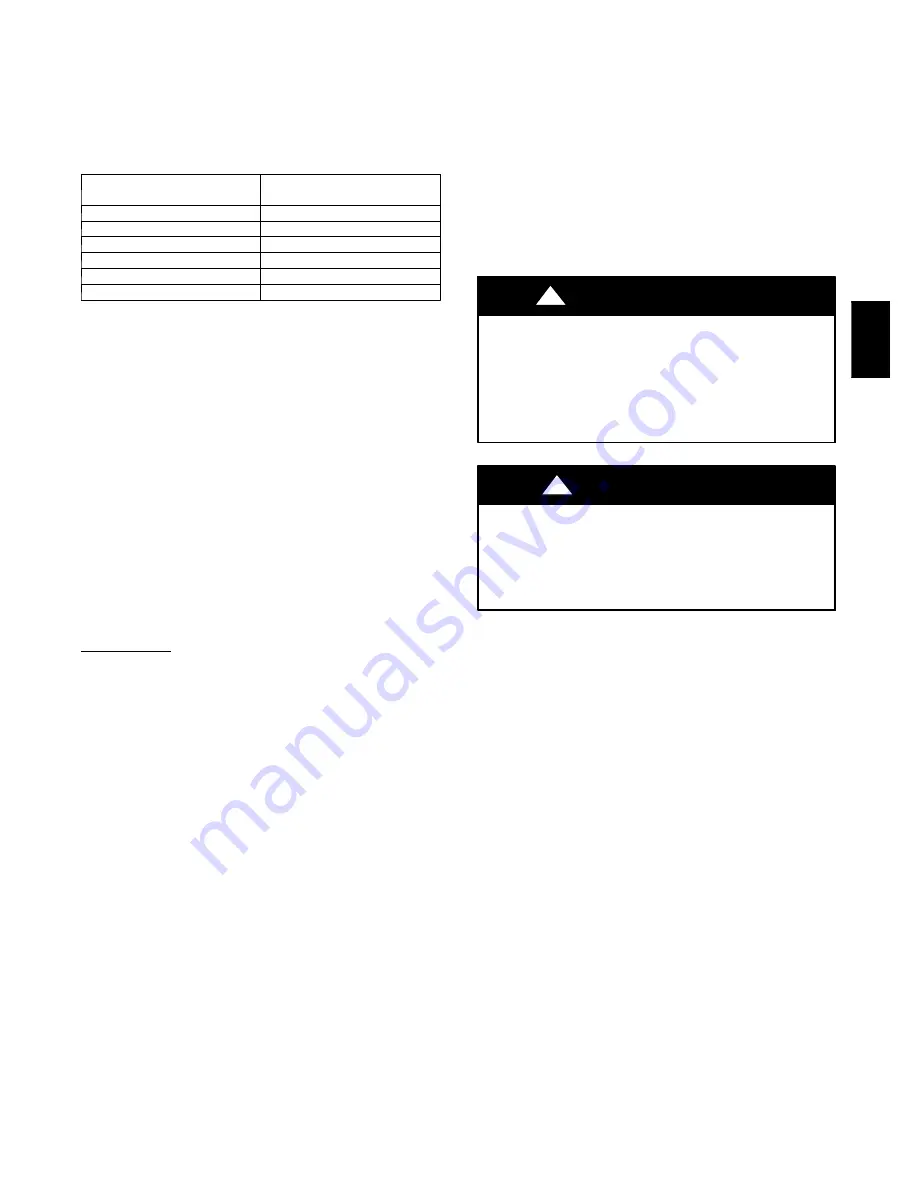

Table 2 – Minimum Floor Area For Unconfined Space

FURNACE

INPUT BTUH / kW

MINIMUM FT

2

(M

2

) WITH

7---1/2 FT (2.3 M) CEILING

70,000

467 (43.4)

91,000

607 (56.3)

105,000

700 (65.0)

119,000

793 (73.6)

140,000

933 (86.6)

154,000

1026 (95.3)

Many new buildings and homes (and older ones that have been

weatherized) MUST BE considered as being of tight construction,

therefore infiltration will not be sufficient to supply necessary air

for combustion and ventilation.

A building can be considered as being of tight construction when:

1. Walls and ceilings exposed to outside atmosphere have a

continuous water vapor retarder with a rating of 1 perm or

less with openings gasketed or sealed; and/or

2. Weatherstripping has been added on operable windows and

doors, and/or caulking or sealants are applied to areas such

as joints around windows and door frames; between sole

plates and floors; between wall--ceiling joints; between wall

panels; at penetrations for plumbing, electrical, and fuel

lines; and at other openings.

If combustion and ventilation air must be supplied to an

unconfined space from outside, an opening with a FREE AREA of

not less than 1 in.

2

per 5,000 BTUH (4400 mm

2

/ kW)of total

input of all appliances within unconfined space (but not less than

100 in.

2

(64516 mm

2

) must be provided. This opening must be

located such that it cannot be blocked at any time.

Confined Space

A confined space has a volume of less than 50 ft

3

(1.4 M

3

) per

1,000 BTUH of the total input rating for all appliances installed in

that space.

NOTE

: In calculating free area, consideration shall be given to

blocking effect of louvers, grilles, or screens protecting openings.

Screens used shall not be smaller than 1/4--in. (6 mm) mesh and

shall be readily accessible for cleaning. If free area through a louver

or grille is known, it shall be used in calculating size and free area

specified. If design and free area are not known, it may be assumed

that wood louvers have 20% free area and metal louvers and grilles

have 60% free area. Louvers shall be fixed in open position or

interlocked with furnace so they open automatically at furnace

start--up and remain open during furnace operation.

The size of the openings depends upon whether the air comes from

outside of the structure or an unconfined space inside the structure.

All Air From Inside the Structure

For a confined space, where air is taken from an interior space, 2

permanent openings of equal area are required. One opening must

be within 12 in. (305 mm) of ceiling and the other within 12 in.

(305 mm) of floor.

All Air From Outside of Structure

If outside air is supplied to a confined space, then the 2 openings

must be equal and located as above.

1. If combustion air is taken through a permanent opening

directly communicating with the outdoors, the opening shall

have a minimum free area of 1 in.

2

per 4,000 BTUH (550

mm

2

/kW)of total input rating for all equipment in the

enclosure.

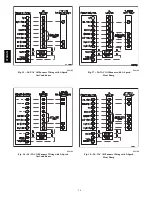

2. If combustion air is taken from outdoors through vertical

ducts, the openings and ducts MUST have at least 1 in.

2

of

free area per 4,000 BTUH of the total input for all

equipment within the confined space. (See Fig. 4 and 5.)

3. If combustion air is taken from outdoors through horizontal

ducts, the openings and ducts MUST have at least 1 in.

2

of

free area per 2,000 BTUH (1100 mm

2

/kW)of the total input

for all equipment within the confined space. (See Fig. 6.)

When ducts are used to supply air, they must be of the same cross

sectional area as free area of openings to which they connect. (See

Fig. 7.)

The minimum dimension of rectangular air ducts must not be less

than 3 in. (76 mm).

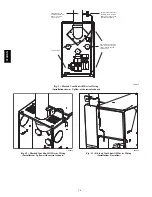

Step 3 — Ductwork Recommendations

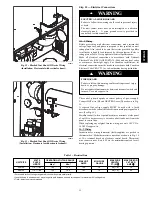

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or death.

When supply ducts carry air circulated by furnace to areas

outside spaces containing furnace, return air MUST also be

handled by a duct sealed to furnace casing and terminating

outside space containing furnace.

!

WARNING

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation.

Return--air grilles and warm air registers MUST NOT be

obstructed.

CAUTION

!

The proper sizing of warm air ducts is necessary to ensure

satisfactory furnace operation. Ductwork should be in accordance

with the latest editions of NFPA--90A (Installation of Air

Conditioning and Ventilating Systems) and NFPA--90B (Warm Air

Heating and Air Conditioning Systems) or Canadian equivalent.

The supply ductwork should be attached to flanged front opening

provided at discharge end of furnace. The return--air ductwork

should be attached to flanged rear opening of furnace. See Fig. 2

for dimensions of these openings.

NOTE

: The blower access opening should not be used for return

air.

The following recommendations should be followed when

installing ductwork:

1. Install locking--type dampers in all branches of individual

ducts to balance out system. Dampers should be adjusted to

impose proper static at outlet of furnace.

2. A flexible duct connector of noncombustible material

should be installed at unit on both supply-- and return--air

systems. In applications where extremely quiet operation is

necessary, the first 10 ft. (3.0 M) (if possible) of supply and

return ducts should be internally lined with acoustical

material.

3. In cases where return--air grille is located close to fan inlet,

there should be at least one 90

_

air turn between fan inlet

and grille. Further reduction in sound level can be

accomplished by installing acoustical air--turning vanes or

lining duct as described in item 2 above.

4. When a single air grille is used, duct between grille and

furnace must be the same size as return opening in furnace.

374RAN