I s - C r e a m

28

the effort required by the gear motor to mix it. Using the electricity consumption value, the electronic control system is able to

determine the effort applied and when it reaches a set level, the solenoid valve is closed, thereby shutting off the supply of

refrigerant gas to the ice cream cylinder.

At this point the mixing system reduces its speed (P04) and the cooling system is used to keep the ice cream product reserve

contained in the upper tank refrigerated. At predefined intervals (P20), the mixing system increases its speed (P03) and, if

necessary, the proper density of the ice cream will be restored by opening the respective solenoid valve.

When the dispensing tap is opened, the mixing system increases its speed (P05) in order to quickly dispense a certain quantity of

ice cream. The same quantity of ice cream mix drops down by the force of gravity from the upper tank into the lower cylinder.

In order to obtain softer and lighter ice cream, it is necessary that a certain quantity of air enters the cylinder together with the ice

cream mix. For this purpose, the machine is equipped with a special mixing pipe, the correct use of which is illustrated in the

instruction manual.

Setting the density of the product to between 1 and 10 makes it possible to obtain a product with the required level of density. By

default the maximum setting, i.e. when the density is set to 10, corresponds to an electrical power consumption of 300 Watts (P12),

which can be increased to 400 Watts.

When the ice cream production operating mode is selected, the compressor is always on. When the dispenser is turned on, after

the 60 second safety delay (P15), the compressor starts up and always stays on.

When the product conservation operating mode is selected, the compressor is only on if at least one of the solenoid valves is open,

i.e., if at least one of the upper tanks requires cooling. Every time the compressor is turned off, a safety time lapse of 60 seconds

(P15) must pass before it can be restarted.

Lastly, the electric motor driving the gear motor is of the brushless type, so its rotation speed can be varied during operation. This

makes it possible to have different speeds depending on whether the dispenser is operating in ice cream production mode or

product conservation mode.

The following operating modes are available:

ICE CREAM PRODUCTION

: in this operating mode, the dispenser prepares the ice cream and the ice cream mix in the upper tank

is kept at a positive conservation temperature.

CONSERVATION:

in this operating mode, the dispenser keeps the liquid ice cream mix at a suitable temperature to preserve it.

This function is useful at night to keep the quality of the ice cream mix intact and limit electricity consumption.

WASHING: in this operating mode, cooling is disabled. This function is useful during machine washing and sanitising to prevent the

solution used from being cooled and freezing.

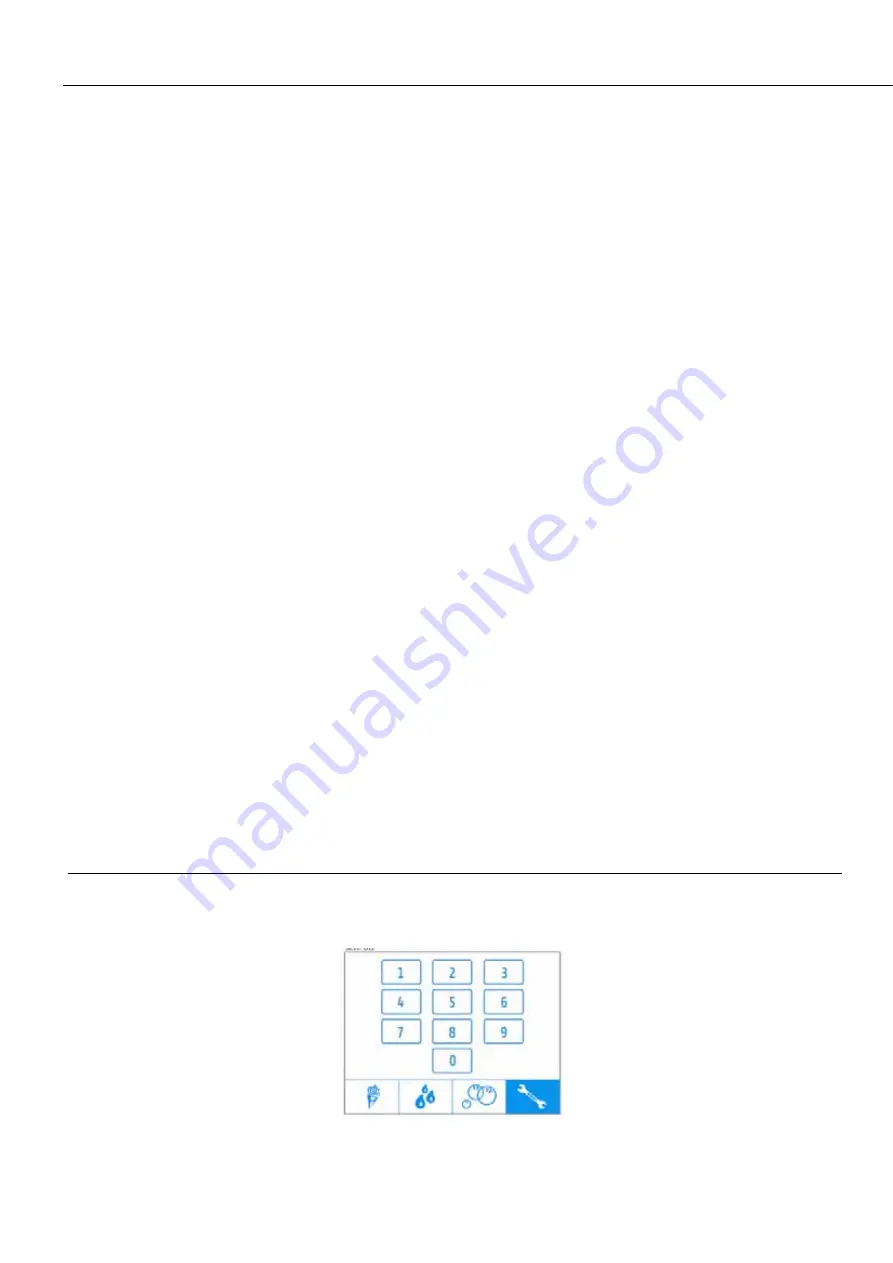

4 PARAMETER SETTING MODE

Press the icon D to access the list of operating parameters. Since access to this function can be protected by a security password,

the following screen will appear.

figure 3

By pressing the icon D again, without entering any password, you can access the list of user parameters (PA00 - PA09). By entering

Содержание Is-Cream

Страница 1: ...Is Cream MANUALE DI SERVIZIO SERVICE MANUAL...

Страница 2: ...Is Cream...

Страница 25: ...25...

Страница 47: ...43 NOTE NOTES NOTES ANMERKUNGEN NOTAS...

Страница 48: ...2477_99 R0 2 15A07...