CS6140, CS6140B Series Turning machine

Instructions

15-2

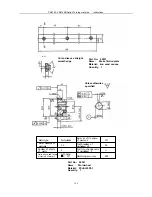

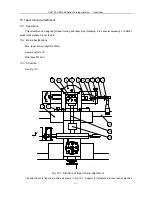

saddle (2) with 2-M6 screws and 2-10 taper pins. Bracket (9) is fastened to machine bed (10) with taper pins. When

operating, I-shaped sliding block (3) moves along plate (4) and sliding slot (5) moves along scale (6) that is

connected with graduation plate (7) with taper pins.

15.4 Setting up

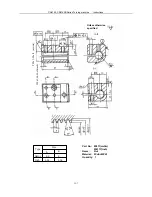

Before using, the scale, which swings back and forth in the graduation plate around the shaft pin, must be

properly adjusted so that it points to correct graduation mark as required by the work piece to be turned. Rotate the

adjusting screw arbor till the scale is pointed in position, and fasten it to the graduation plate with two T-slot screws.

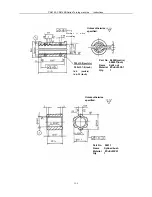

During operation the tool will move a taper path, thus a taper is turned. During taper turning some length of

cylindrical surface is always cut due to mechanical backlash. So it is necessary to take a test operation to find the

length (it varies with different taper work pieces). After setting up the tool, true turning cannot be taken unless the

said length is eliminated by moving the carriage a same distance to the right using the apron handwheel.

15.5 Caution

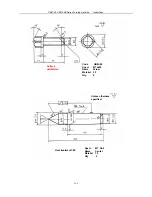

When the taper turning attachment is not to be used, bracket (8) must be removed. Some adjustment should

be made so that the scale is pointed to zero. Fasten T-slot screws (12) and lock I-shaped sliding block (3) using two

pointless set screws (13) to stop the drive screw from sliding back and forth.

When it is necessary to check the terminal block for trouble removing, take off the taper turning attachment

first.

Every running parts of the attachment should be lubricated with an oil gun every shift of work to reduce wear

and guarantee operation.

Содержание CS6140 Series

Страница 16: ...CS6140 CS6140B Series Turning machine Instructions 4 3 Fig 4 2 Bearing location diagram ...

Страница 31: ...CS6140 CS6140B Series Turning machine Instructions 6 2 Fig 6 1a Location of electrical parts ...

Страница 32: ...CS6140 CS6140B Series Turning machine Instructions 6 3 Fig 6 1b Location of electrical parts of CS6266B ...

Страница 33: ...CS6140 CS6140B Series Turning machine Instructions 6 4 Fig 6 2a Electric schematic diagram 1 ...

Страница 34: ...CS6140 CS6140B Series Turning machine Instructions 6 5 Fig 6 2a Electric schematic diagram 2 ...

Страница 35: ...CS6140 CS6140B Series Turning machine Instructions 6 6 Fig 6 2b Electric schematic diagram of CS6266B 1 ...

Страница 36: ...CS6140 CS6140B Series Turning machine Instructions 6 7 Fig 6 2b Electric schematic diagram of CS6266B 2 ...

Страница 48: ...CS6140 CS6140B Series Turning machine Instructions 10 2 ...

Страница 60: ...CS6140 CS6140B Series Turning machine Instructions 11 12 Fig 11 12b Structure of spindle nose ISO702 Ⅱ No 8 ...