Main electronic control/ignition p.c.b.

15

PARAMETER

DIGIT VALUES

Chimney

sweep

function

Pr 09 00

= No chimney

sweep fun (factory

set)

01

= Low power

sweep---test

04

= C.h. power

sweep---test

07

= D.h.w. power

sweep---test

C.h. reignition fre-

quency

Pr 10 00

÷

99

(0÷600 sec.)

(factory set

30

= 3

minutes)

C.h. pump post---cir-

culation

Pr 11 00

÷

99

(0÷600 sec.)

(factory set

10

= 1

minute)

Max. useful output in

c.h. mode

Pr 12 00

÷

99

(0÷100%)

factory set:

99

= Activ A 12OV

99

= Activ A 15OV

99

= Activ A 20OV

99

= Activ A 25OV

C.h. pump working

type

Pr 13 00

= Depends on

room

thermostat

(factory set)

04

= Always running

Ignition power

Pr 14 00

÷

99

(0÷100%)

factory set:

Natural gas (G20)

30

= Activ A 12OV

30

= Activ A 15OV

30

= Activ A 20OV

40

= Activ A 25OV

Propane (G31)

40

= Activ A 12OV

40

= Activ A 15OV

40

= Activ A 20OV

40

= Activ A 25OV

K value (external

probe diagram)

Pr 15 01

(=0,1)÷

60

(=6,0)

K value

factory set:

00

= Off

Not used

Pr 16

D.h.w. burner turn off

function

Pr 17 00

= Burner off at

fixed d.h.w. = 65

˚

C

(factory set)

01

= Brurner off at

set point +5

˚

C

NTC on the c.h. re-

turn

Pr 18 00

= Probe not pres-

ent

(factory set)

01

= Probe present

PARAMETER

DIGIT VALUES

Not used

Pr 19

Not used

Pr 20

Not used

Pr 21

Not used

Pr 22

Not used

Pr 23

Not used

Pr 24

Not used

Pr 25

Not used

Pr 26

C.h. minimum set-

point

Pr 27 25

÷

45

(factory set

25

˚

C)

Tab. 6.1

6.5

Checks

n

Check that the fuses are complete

If the

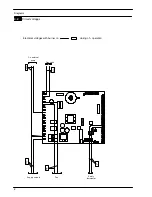

Main electronic control/ignition p.c.b.

does not

supply any device (pump, fan, etc.) check that the

fuses 10 (Fig. 6.2) are complete.

If a fuse has blown replace it with one that has the same

characteristics after having identified the reason for fail-

ure.

n

Lock sequence

Start the boiler until the burner is ignited.

With the burner firing, interrupt the gas supply. The

Main electronic control/ignition p.c.b.

must carry out

four complete ignition cycles and then, after about 4

minutes, goes to lock---out state.

Switch off and on the electricity supply to the boiler, by

means of the fused spur isolation switch, the device

must not unlock and the burner must not turn on

6.6

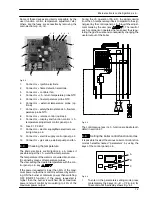

Removal of the electronic control p.c.b

Warning: isolate the boiler from the mains

electricity supply before removing any

covering or component.

When replacing the

Main electronic control/ignition

p.c.b.

all parameters must be correctly checked /

adjusted accordingly with the values noted in table

in the installation manual see chapter COMMIS-

SIONING section: Setting record (for information on

parameters see also section 6.4).

1

Remove all the body panels (see section 2.2).

2

Gain access to the parts located inside

the Main

electronic p.c.b. box

as explained in the section

2.4 of this manual.

3

Remove all the wiring connected to the

Main elec-

tronic control/ignition p.c.b.

.

Содержание Activ A 12OV

Страница 28: ...Temperature probe 26 D F B Fig 9 4...