Main electronic control/ignition p.c.b.

14

Fig. 6.5

2

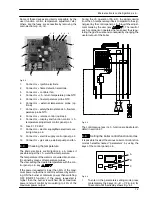

To move through the parameters press c.h. set

keys (A or C Fig. 6.6)

A

C

Fig. 6.6

3

The display shows Fig. 6.7

Fig. 6.7

4

To modify the parameter press contemporary the

keys (A --- B Fig. 6.8)

A

B

Fig. 6.8

5

To change the parameters press c.h. set keys (A

or C Fig. 6.6)

6

To memorize the setting press the key (B Fig. 6.9)

B

Fig. 6.9

7

To exit for setting without modifing the set press

the keys (B --- C Fig. 6.10)

C

B

Fig. 6.10

To reset the boiler to the normal operation press con-

temporary the 3 keys (A --- B --- C Fig. 6.4) for 10 sec-

ond.

The following table gives details of each parameter and

the possible value that can be set.

Important: at the end of the setting operation it is im-

portant to fill/update the table in the installation

manual see chapter COMMISSIONING section: Set-

ting record.

PARAMETER

DIGIT VALUES

Boiler type (to be up-

dated with the com-

plete range)

Pr 01 00

= No power Er 99

18

= Activ A 12OV

19

= Activ A 15OV

20

= Activ A 20OV

21

= Activ A 25OV

Not used

Pr 02

Not used

Pr 03

Not used

Pr 04

Gas type

Pr 05 00

= G20 Natural

05

= G31 Propane

Not used

Pr 06

C.h. flow max

temperature

˚

C

Pr 07 85

÷

45

(factory set

85

˚

C)

Factory parameters

reset

Pr 08 00

= No reset

04

= All parameters

return to factory set

with the exclusion of

Pr 01 and Pr 05

39

= All parameters

return to factory set

included Pr 01

and Pr 05

Содержание Activ A 12OV

Страница 28: ...Temperature probe 26 D F B Fig 9 4...