INSTALLATION MANUAL

ENGLISH

12) AUTOMATION OPERATION

Since the automation system can be remotely controlled by means of a radio

control device or a Start button, and therefore out of sight, all safety devices

must be frequently checked in order to ensure their perfect efficiency. In

the event of any anomalous operation, request immediate assistance from

qualified personnel.

Children must be kept at a safe distance from the automation operation

area.

13) CONTROL

The automation system allows motor-driven gate opening and closing

operations to be carried out. Various types of control are provided (manual,

radio control, magnetic card access control etc.) depending on the installa-

tion requirements and characteristics. See the specific instructions for the

various control systems. All automation system users must be instructed on

automation control and operation.

14) MAINTENANCE

Before carrying out any maintenance to the installation, disconnect the

mains power supply.

• Periodically check that hinge-pivots are in good condition and

properly greased.

•

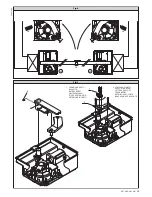

Grease the pin on the foundation case every two years, using the appro-

priate greaser (C) located on the lever (A) as shown in Fig.9.

The type of grease recommended is: R

ocol

F

oodlube

M

ultipaste

.

• Occasionally clean the photocell optical components.

• Have a qualified technician (installer) check the correct setting of the

electric clutch.

• If the power supply cable is damaged, it must be replaced by the manu-

facturer or its technical assistance service, or else by a suitably qualified

person, in order to prevent any risk.

• When any operational malfunction is found, and not resolved, disconnect

the mains power supply and request the assistance of a qualified technician

(installer). When automation is out of order, activate the manual release

to allow the opening and closing operations to be carried out manually.

15) NOISE

The aerial noise produced by the gearmotor under normal operating condi-

tions is constant and does not exceed 70dB(A).

16) SCRAPPING

Materials must be disposed of in conformity with the current regulations.

In case of scrapping, the automation devices do not entail any particular

risks or danger. In case of recovered materials, these should be sorted out

by type (electrical components, copper, aluminium, plastic etc.).

17) DISMANTLING

When the automation system is disassembled to be reassembled on another

site, proceed as follows:

• Disconnect the power supply and the entire electrical installation.

• Remove the gearmotor from its fixing base.

• Disassemble the control panel, if separate, and all installation compo-

nents.

• In the case where some of the components cannot be removed or are

damaged, they must be replaced.

18) MALFUNCTION: CAUSES AND REMEDIES

When any operational malfunction is found, and not resolved, discon-

nect the mains power supply and request the assistance of a qualified

technician (installer).

When automation is out of order, activate the manual release to allow the

opening and closing operations to be carried out manually.

During this period of time, keep the lock in the closed position by means of

a chain and padlock.

18.1) The gate does not open. The motor does not turn.

a) Check that the photocells or electric edges are not dirty, or impregnated,

or misaligned. Proceed accordingly.

b) Check that the electronic appliance is correctly supplied. Check the

integrity of the fuses.

c) Check that the individual devices operate correctly.

d) If the control unit does not work, it must be replaced.

In the case where the above-mentioned checks give no results, contact

an authorised customer service centre.

If the supply cable is damaged, it must be replaced by the manufacturer,

by its technical service center or, in any case, by a qualified technician

so as to avoid any risk.

18.2) The gate does not open. The actuator vibrates but there is no

movement.

a) Check that the capacitor is connected to the motor running terminals.

b) Check that the common wire of the motor (light blue) is correctly con-

nected.

c) Disconnect and reconnect the mains power supply. The first Start command

must open. Should the actuator move to the closing function, reverse the

respective running connections.

d) Manually help the leaf opening operation. If the leaf opens, check whether

there are any mechanical problems. In the case where the above-men-

tioned checks give no results, increase the torque in the control unit and,

if necessary, contact a qualified technician.

WARNINGS. Correct operation of the actuator is only guaranteed when

the data specified in this manual are respected.

The company cannot be held responsible for any damage caused by

failure to observe the installation standards and directives specified

in the present manual.

The descriptions and illustrations contained in the present manual are

not binding. The Company reserves the right to make any alterations

deemed appropriate for the technical, manufacturing and commercial

improvement of the product, while leaving the essential product fea-

tures unchanged, at any time and without undertaking to update the

present publication.

14

-

ELI-250 - Ver. 08

D811232_08

Содержание ELI-250

Страница 2: ... ELI 250 Ver 08 D811232_08 ...

Страница 28: ...Fig 4 Fig 3 Fig 6 Fig 7 Fig 5 180 S VR 500 400 336 420 70 145 min 70 D D 28 ELI 250 Ver 08 D811232_08 ...

Страница 31: ...Fig 14 2 1 Max 90 ELI 250 Ver 08 31 D811232_08 ...

Страница 32: ......