MAINTENANCE

67

—

One to two leak checks per year performed with a certified

leak detector and a qualified person

— To reduce waste, the refrigerant and the oil must be in com-

pliance with current legislation, using methods that limit the

losses of refrigerant and the pressure drops and with the ma-

terials suitable for the products.

Detected faults and leaks must be repaired immediately.

The compressor oil that is recovered during maintenance contains

refrigerant and must be treated accordingly.

The coolant under pressure must not be drained in the open air.

If a refrigerant circuit is opened, plug all openings, if the operation

takes up to a day; for longer periods, load the circuit with nitrogen.

NOTA:

Any deviation or non-compliance with the maintenance cri-

teria will void the warranty conditions of the unit and the manufac-

turer can no longer be held responsible.

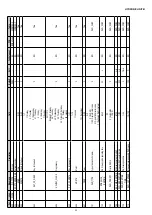

4.2 Tightening torque for main electrical connections

Component

Unit designation

Value (N.m)

Main switch (option 70)

L1 /L2 /L3/N/PE

2,00

Terminal X1

L1 /L2 /L3/N/PE

1,5 - 1,8

Terminal X3

0,6 - 0,8

Contactor (power and control)

1,50

Thermal relay

2,50

Transformer

1,70

Connections on the compressor

Screw on phases (only for 21kW)

2,50

Compressor speed variator

6 nuts M10

L1 /L2 /L3/N

1,20

2 nuts M10 or M8

PE

1,20

9 nuts M8 (with fuses and bars)

01/02/03

1,20

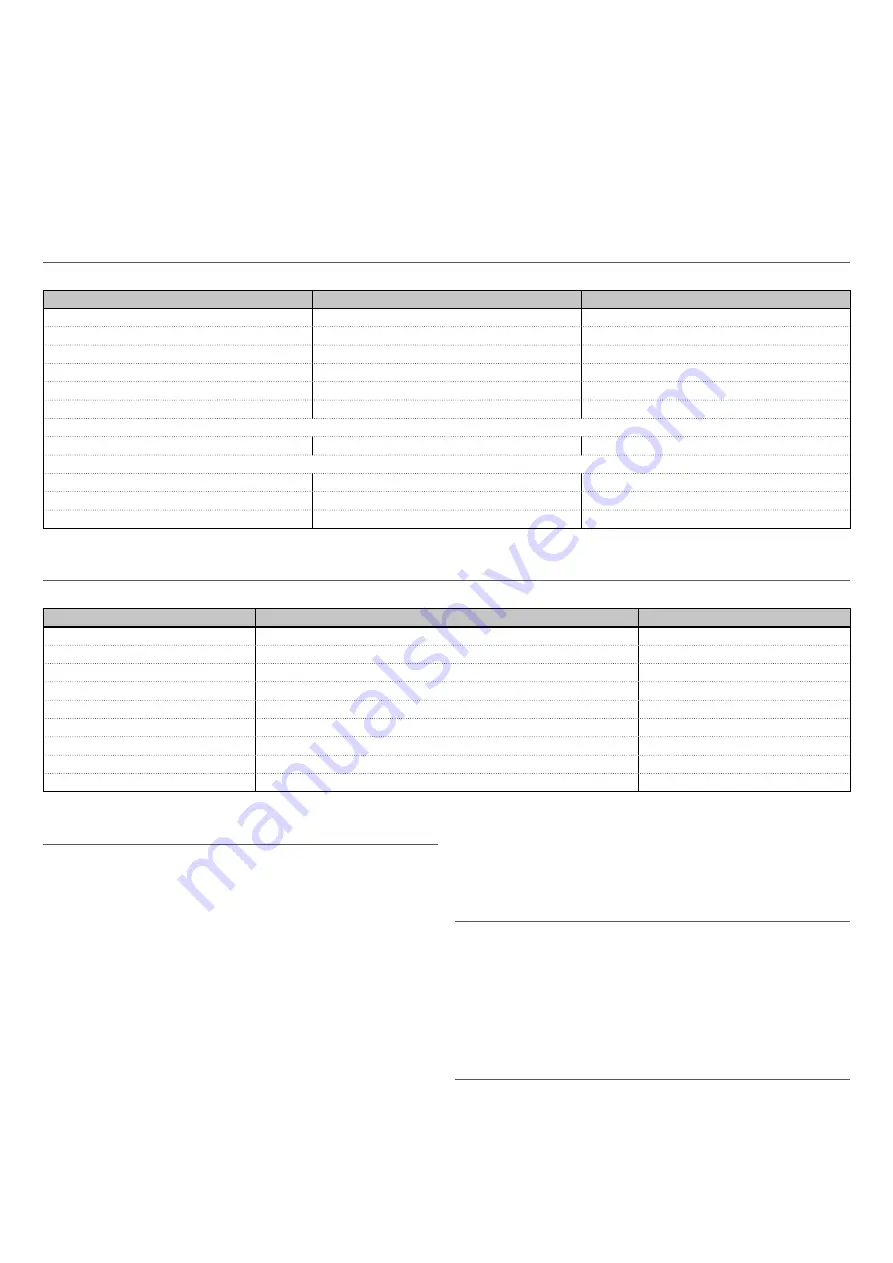

4.3 Tightening torque for main screws and nuts

Screw type

Use

Value (N.m)

Wood screw H M8

Assembly of the frame on the pallet

13,00

Nut H M8

Fixing the compressor on the base and fixing the plate exchanger and receiver

15,00

Self-tapping screw D=4,2mm

Sheet metal parts, plastic grid and electrical components

4,20

Self-tapping screw D=3mm

Mounting the deflector on the front panel

2,00

Self-tapping screw M6

Fan sub-assembly and assembly of the frame on the feet

7,00

Screw M8

Water pump unit on the partition panel

15,00

Gas nutD D1” e D1”1/4”

Inlet and outlet group of heat pump pipes

70,00

Gas nut D1/2”

Water filling system and nut assembly on the suction pipe of the water pump

20,00

Nut H M6

Fan propeller assembly on the fan motor

7,00

4.4 Air side heat exchanger

It is advisable to regularly inspect the finned coils to verify their

degree of soiling. It depends on the environment in which the unit

is installed, and will be worse in urban and industrial installations

and near deciduous trees.

For cleaning the finned coil, there are two maintenance levels:

— If the air heat exchangers are clogged, gently clean them ver-

tically with a brush.

— Work on the air heat exchangers with the fan off.

— For this type of operation, turn off the unit if, having made all

the appropriate service considerations, it is considered ap-

propriate.

— Clean the air heat exchangers to ensure optimal unit opera-

tion. This cleaning is necessary when the air heat exchang-

ers start to get dirty. The frequency of cleaning depends on

the season and the location of the unit (area exposed to the

wind, forest, dusty, etc.).

—

Clean the finned coil with suitable products.

9

Never use pressurized water without a large diffuser. Do not

use high pressure cleaners for Cu / Cu and Cu / Al coils.

Concentrated or rotating water jets are strictly prohibited. Never

use liquid with a temperature higher than 45 ° C to clean the air

heat exchangers.

Proper and frequent cleaning (approximately every three months)

will avoid 2/3 of the corrosion problems.

4.5 Plates heat exchanger maintenance

Check that:

—

The insulating foam is intact and firmly in place.

— the BPHE and the electric pipe heaters are in operation, and

correctly positioned securely.

— the connections on the water side are clean and do not show

signs of leaks.

4.6 Maintenance

9

Before any intervention on the unit, make sure that the circuit

is isolated and that there is no voltage. Note that it may take 5

minutes for the circuit capacitors to fully discharge after isolat-

ing the circuit. Only qualified personnel are authorized to work

on the VFD.

In case of alarm or persistent problem related to the VFD, contact

Содержание 20161618

Страница 1: ...HYDRONICUNITB EN Installer manual...