INSTALLATION

32

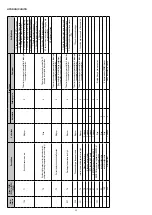

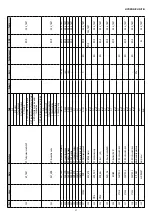

use the following table:

Model

5

7

11

15

11T

15T

Electrical characteristics

Power supply

V/ph/Hz+N

230/1/50

400/3/50

Permitted voltage

V

220 - 240

380 - 415

Total power input

(1)

kW

1,80

3,38

4,73

5,18

10,32

Cos Phi at max. power absorbed

0,98

Full load current

(2)

A

8,90

16,70

23,30

25,60

16,80

Switch magnetermic

A

10

16

25

16

Fuse

A

16

20

32

20

Power cable

n. x mm²

3 x 2,5

3 x 4

5 x 2,5

Power cable

Type

H07 RN-F

(1)

Power absorbed by the compressors and fans at the limit operating conditions (i.e. with a saturated inlet temperature of 15 °C and a condensation

temperature equivalent to 68.3 °C) with a rated supply voltage of 400 V

(2)

Maximum unit operating current

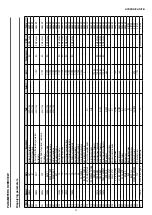

— apply the ferrite ring on the power supply cable to ensure

compliance with EMC standards

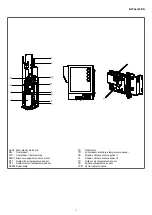

Ferrite rings installation:

— The 5 - 7 models do not need ferrite rings.

— The models 11 and 15 with single phase electrical suppy

need a ferrite ring (supplied with the unit) installed on phase

and neutrak cabes (L*N), near the electrical supply therminal

block.

— The 11T e 15T three phases models needs two ferrite rings

(suppy with the unit), one installed near the electrical sup-

ply therminal block around the phases and neutral cables,

the other on the same calbles but just inside the unit frame,

where the cables enter in the unit frame.

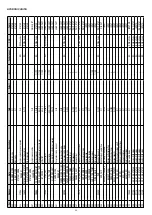

— Once the electrical connections are complete, reassemble all

the components operating in reverse order.

Check that:

— the characteristics of the electrical network are adequate for

the absorption of the appliance, also considering any other

machinery in parallel operation

— the power supply voltage corresponds to the nominal value

+/- 10%, with a maximum phase imbalance of 3%

— all disconnection devices from the power supply must have

a contact opening (4 mm) to allow total disconnection in ac-

cordance with the conditions foreseen for overvoltage class

III

Mandatory items:

— the use of an omnipolar magneto-thermal switch, padlockable

line disconnector, compliant with CEI-EN Standards (contact

opening of at least 4 mm), with adequate breaking capacity

and differential protection, installed near the appliance

— connect the device to a properly functioning earthing system

— make sure that the electrical power supply system is compli-

ant with the current national safety standards

— make sure that the power supply line impedance is consistent

with the unit's power consumption, as indicated on the unit's

data plate

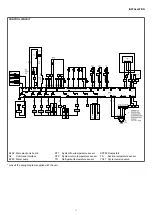

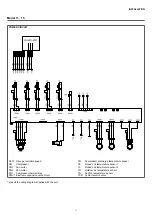

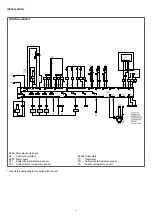

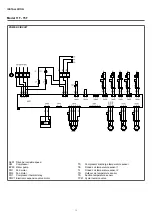

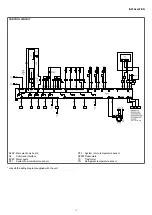

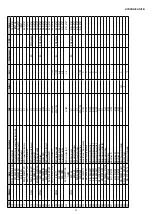

— for any electrical intervention, always refer to the wiring dia-

grams contained within this booklet

0

Do not use gas and water pipes to ground the unit.

0

It is forbidden to pass the power supply and room thermostat

cables near hot surfaces (delivery pipes). If contact with parts

above 50 ° C is possible, use a suitable type of cable.

Содержание 20161618

Страница 1: ...HYDRONICUNITB EN Installer manual...