22

80-0042-00, Rev. 06.9

MAINTENANCE

Troubleshooting

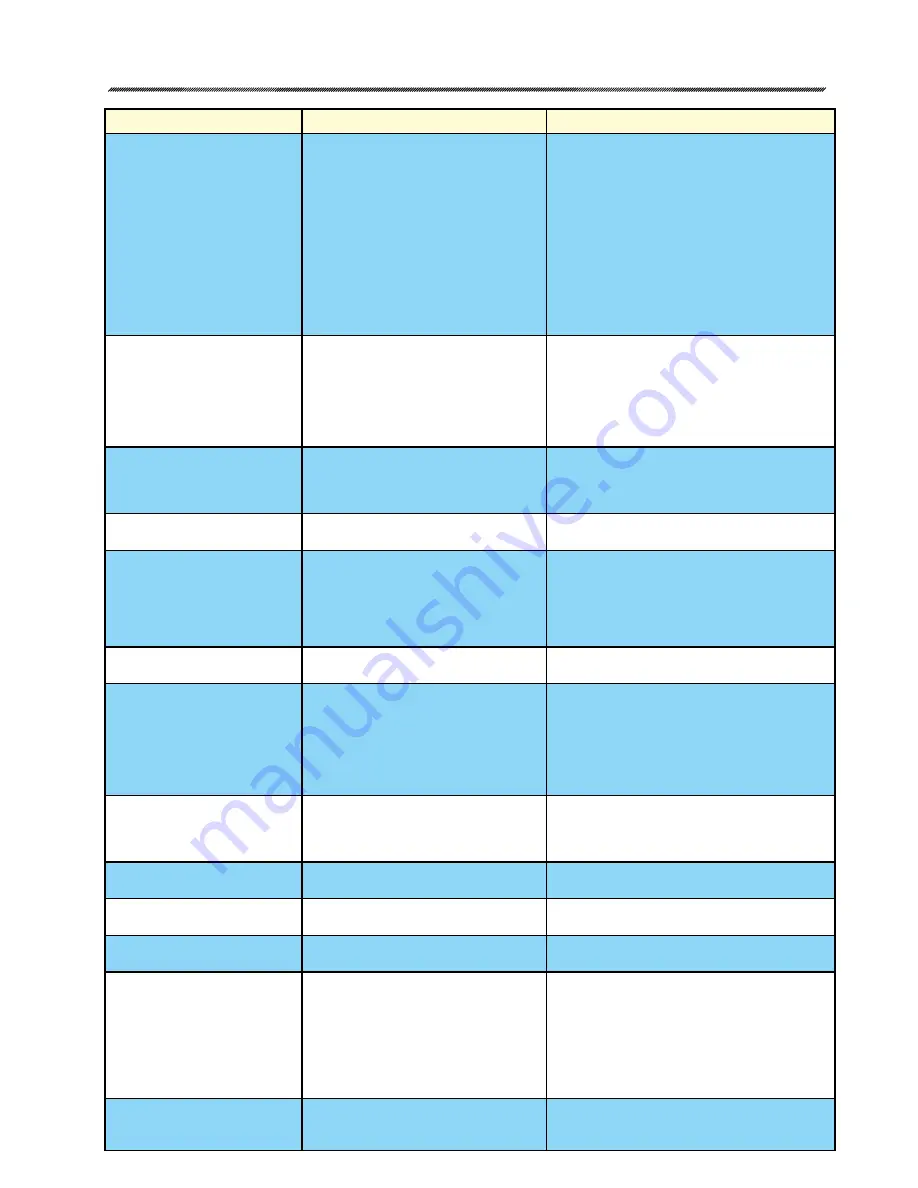

CONDITIONS

POSSIBLE CAUSES

CORRECTIONS

Actuator will not run in either

direction with input signal

applied.

a.

b.

c.

d.

e.

f.

g.

Handswitch left in wrong position.

No 120 Vac line supply. No lamps lit

on control board.

Fuse F-1 open. No lamps lit on

control board.

External auto/man switch in wrong

position (Position-all).

Torque on driven load shaft exceeds

actuator torque rating. "S" LED on.

Input signal below range or reversed.

"L" LED on.

Control board failure.

a.

b.

c.

d.

e.

f.

g.

Return Handswitch to auto position.

Check fuses and switches in power panel.

Check for possible shorts, then replace

fuse. Use only Beck part no. 11-1370-10 for

proper protection of triacs.

Return switch to auto position.

Check operation with Handswitch and

remove obstruction.

Input signal voltage between terminal 11 and

12 (+) must be between 1-5 Vdc.

Replace control board.

Actuator runs only in one

direction in auto and both

directions with Handswitch in

forward or reverse.

a.

b.

c.

d.

Zero adjustment incorrect.

Loss of signal feature activated and

actuator set to go to full forward or

reverse position. "L" LED is on.

Loss of feedback signal.

Control board failure.

a.

b.

c.

d.

Readjust Zero. See calibration, p.17.

Check input signal against LOS trigger.

Check feedback signals at terminals 13, 14

or 15.

Replace control board.

Actuator runs in the wrong

direction with input signal

applied.

a.

b.

Input signal reversed. "L" LED on.

Wiring to limit switches reversed.

a.

b.

Check polarity of input signal. Terminal 12 is

positive, 11 negative.

Check limit switch connections. See Limit

Switch adjustment, p.12.

Actuator shaft position

oscillates.

a.

b.

Excessive noise on input signal.

Control board failure.

a.

b.

Check input signal.

Replace control board.

Actuator does not stop at

normal or desired limit of shaft

travel.

a.

b.

c.

d.

Span or Zero adjusted incorrectly.

Limit switches adjusted incorrectly.

Loss of input signal. "L" LED on.

Limit switch failure.

a.

b.

c.

d.

Check control board calibration. See

calibration procedure, p.18.

Readjust limit switches. See limit switch

adjustment, p.12.

Restore input signal to actuator.

Replace limit switch. Contact factory.

Loss of signal feature does not

function.

a.

Control board failure.

a.

Replace control board. See p.19.

Actuator activates to full retract

or extend position and stays.

a.

b.

c.

d.

Handswitch left in forward or reverse

position.

Loss of input signal when LOS go to

position is selected. "L" LED on.

Loss of feedback signal.

Control board failure.

a.

b.

c.

d.

Return forward/reverse Handswitch (S1) to

center STOP position.

Restore input signal to drive.

Check feedback signal at terminals 13, 14

or 15.

Replace control board.

Actuator movement erratic while

driving from full extend to full

retract and runs normally from

full retract to full extend.

a.

b.

Feedback potentiometer dirty. Loss

of wiper contact moves actuator in

reverse direction.

Feedback potentiometer open.

a.

b.

Replace feedback potentiometer.

Replace feedback potentiometer.

Actuator moves uncontrollably

to position, then oscillates.

a.

Feedback potentiometer open.

a.

Replace feedback potentiometer.

Pilot LED light out.

a.

b.

No power.

Control section transformer failure.

a.

b.

Check power sources.

Replace control section transformer.

Feedback signal decreases

when it should increase.

a.

Plug P4 in wrong position on control

board.

a.

Check feedback calibration procedure. See

p.16.

Feedback signal does not

reach maximum, but low end

calibration is correct.

a.

b.

c.

d.

Output overload; load resistance is

too low for voltage range or too high

for current range.

Low voltage.

Feedback pot. not set correctly.

Incorrect actuator feedback

configuration

a.

b.

c.

d.

Check load resistance against suggested

feedback signal terminal hookup.

Check line voltage at terminal board.

Check feedback calibration procedure, p.16.

Check feedback calibration procedure for

correct R2 component on terminal board.

See p.16.

Actuator does not reach desired

travel limit.

a.

Physical obstruction; e.g., valve

jammed or load exeeds actuator

rating. "S" LED on.

a.

Check operation with Handswitch and

remove obstruction.