12

80-0042-00, Rev. 06.9

NOTE: Beck actuators are shipped ready

for installation—no calibration or switch

adjustments are required. The procedures

below are provided in the event that the

application requirements are different from

those originally specified.

CALIBRATION HIERARCHY

The calibration hierarchy provides the

chronological order for performing calibration

procedures. If, for some reason, any or all of the

calibration procedures are required, they should be

performed in the order outlined below:

STEP 1: Adjust travel and auxiliary switches (see

pages 12–14).

STEP 2: Change direction of travel (see page 15).

STEP 3: (Options 5 & 7 only). Calibrate the position

feedback output signal (see page 17).

STEP 4: (Option 7 only) Calibrate the demand input

signal (see page 18).

TRAVEL LIMIT SWITCHES (S3, S4)

All Group 42 actuators are shipped from the

factory with the travel limit switches (S3 and S4)

adjusted to provide the full rated stroke range

unless a reduced stroke is specified at the time of

order. No adjustments are necessary unless the

full stroke length needs to be shortened to meet

different application requirements.

The travel limit switches are labeled S3 and S4,

and correspond to fully retracted and fully extended

positions respectively. These switches must be

set inside the mechanical stop limits to prevent

the actuator from stalling against the mechanical

stops. Depending on the control option ordered,

these switches serve slightly different purposes.

Control option 3 (42-103): S3 and S4 define

the exact fully retracted and fully extended end of

travel point.

Control options 5 & 7 (42-105, 42-107): S3

and S4 provide electrical over-travel protection.

In these versions, the control electronics position

the output and determine the fully retracted and

extended positions during normal operation.

CAUTION

Do not attach the meter or attempt

to adjust the switch cams until the

actuator is discon nected from the

line voltage and auxiliary switches

are disconnected from external

power sources.

Setting the Retract Travel Limit

Switch (S3)

1. Remove the control module cover.

2. Retract the output shaft to the desired travel

limit. For Options 3 & 5, skip to step 3. For

Option 7: De-energize the motor by turning

toggle switch S1 (see Fig. 3) to stop (center

position). Turn the Handwheel until the

position feedback signal (measured across

terminals 14 (+) & 13 (–)) decreases by .005 ±

.001 mA (1.25 mV ± .25). The .005 mA is the

over-travel range. NOTE: If direction of travel

is set for retract on increasing demand, then

turn the Handwheel until the output signal

increases by .005 ± .001 mA (1.25 ± .25 mV).

3. Disconnect the power from the drive.

4.

a. For actuators with Option 3 or 5, connect

the continuity meter across terminals 2

and 9. Rotate the cam (see Fig. 2 next

page) until the meter shows an increase

in resistance from approx. 100 ohms to

more than 1 M ohms (switch contacts

open, switch clicks).

b. For actuators with Option 7, remove the

cable tie holding the switch wires, remove

the two wires from the retract limit switch

(second from the top), and attach the

meter across these contacts. Rotate the

cam (see Fig. 3 next page for method

only--shows S4 connected) until the meter

shows no continuity (switch contacts

open, switch clicks).

5. Disconnect the meter and reconnect switch

wires and actuator power.

6. Extend the output shaft away from the retract

travel limit. Note the direction of rotation of the

lobe of the cam. The correct cam lobe motion

is away from the switch lever and the switch

lever should be on the lower part of the cam.

If this is not correct, return to step 2 and reset

the cam to the proper orientation.

7. Retract the output shaft to the desired travel

limit. If the desired stopping point is reached,

the switch is properly set.

8. For Option 7, redress the switch wires and secure

to the control board standoff with a cable tie.

9. Replace the control module cover.

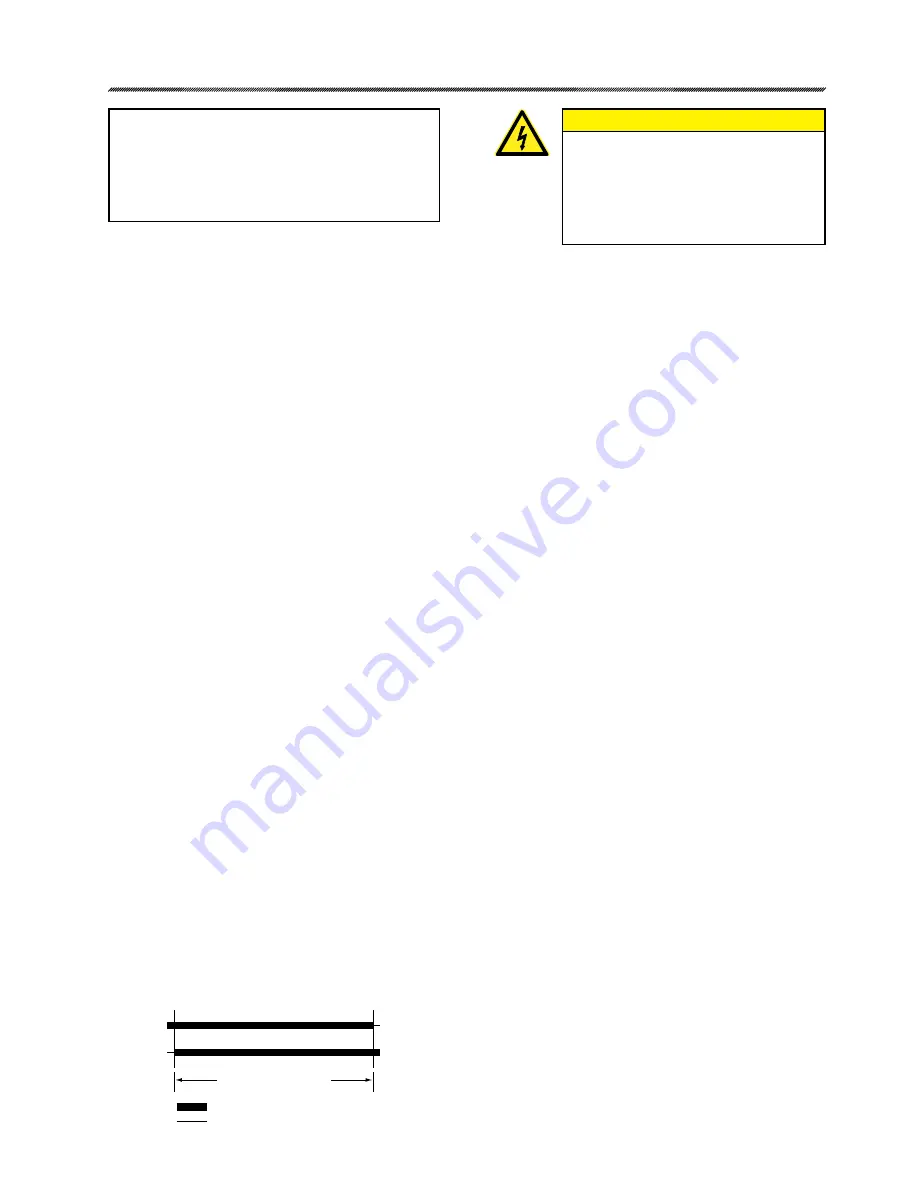

S4

S3

CONTACTS CLOSED

CONTACTS OPEN

TRAVEL

LIMIT SWITCH

SETTINGS

For Option 5 & 7 Drives

switches are set .03” (±.01”)

beyond typical travel range

0% FULLY

RETRACTED

100% FULLY

EXTENDED

CALIBRATION