20-26

®

HYDRAULIC CYLINDER MAINTENANCE

Hydraulic cylinders provide force used to operate booms, attachment, and stabilizers.

Proper

maintenance of cylinders will promote long life and smooth operation. Inspect cylinders daily for leaks or

damage and repair or replace as necessary. Lubricate cylinder grease fittings daily.

See Fig-1

for a typical

high pressure cylinder breakdown and gland bolts torque pattern.

1. Remove cylinder from the machine.

2. Remove the bolts/screws from the gland. Some

cylinders have screw-on gland caps, held in

place with an allen head set screw. If so, remove

set screw and then removing gland cap using an

adjustable chain wrench.

3. Remove hydraulic supply and return lines

(including load lock valves if applicable) from

cylinder to allow free movement of rod.

4. Remove rod assembly from the cylinder barrel.

5. Unscrew the nut from the piston end of the rod

and remove the piston and gland.

6. Before removing old seals, note position they

are in for proper reassembly (see diagram on

next page).

7. Clean and inspect all parts. If worn or damaged,

replace them.

CYLINDER SERVICING & RE-SEAILING

(Cylinder shown may not be type used on your machine but is shown as a reference.)

BARREL

BARREL

BARREL

BARREL

BARREL

(butt & tube assy)

BUSHING

BUSHING

BUSHING

BUSHING

BUSHING

N U T

N U T

N U T

N U T

N U T

ROD

ROD

ROD

ROD

ROD

BUSHING

BUSHING

BUSHING

BUSHING

BUSHING

GLAND

GLAND

GLAND

GLAND

GLAND

PISTON

PISTON

PISTON

PISTON

PISTON

GREASE FITTING

GREASE FITTING

GREASE FITTING

GREASE FITTING

GREASE FITTING

HEX HEAD CAP

HEX HEAD CAP

HEX HEAD CAP

HEX HEAD CAP

HEX HEAD CAP

SCREWS

SCREWS

SCREWS

SCREWS

SCREWS

STROKE

STROKE

STROKE

STROKE

STROKE

LIMITER

LIMITER

LIMITER

LIMITER

LIMITER

GREASE FITTING

GREASE FITTING

GREASE FITTING

GREASE FITTING

GREASE FITTING

10 Bolt Torque Pattern

1

6

2

3

4

8 Bolt Torque Pattern

5

1

6

2

3

4

6 Bolt Torque Pattern

5

7

8

1

6

2

3

4

5

7

8

9

10

Fig-1

Fig-2

SEAL-PISTON

WEAR RING

WEAR RING

O-RING

WEAR RING

WEAR RING

SEAL

SEAL- ROD

WIPER

BACK-UP RING

O-RING

Piston

Gland

SQUARE RING

ROD BUFFER

BACK-UP

RING

05/30/2019

Updated

SERVICE

Содержание 830B

Страница 4: ...THIS PAGE INTENTIONALLY BLANK SUPERIOR WI USA www barko com...

Страница 42: ...THIS PAGE LEFT INTENTIONALLY BLANK...

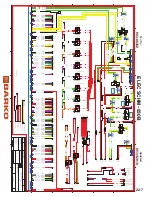

Страница 44: ...20 2 SUPERIOR WI USA www barko com Part No 605 01591 HYD AY WFB 830B 05 30 2019 Updated SERVICE...

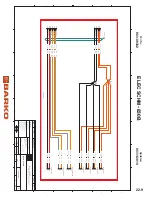

Страница 45: ...20 3 SUPERIOR WI USA www barko com Part No 605 01591 HYD AY WFB 830B 05 30 2019 Updated SERVICE...

Страница 48: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 50: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 54: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 60: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 70: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 94: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 102: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 104: ...THIS PAGE LEFT INTENTIONALLY BLANK...

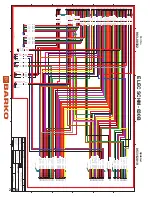

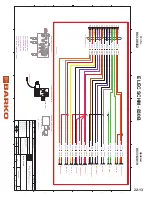

Страница 113: ...26 11 SERVICE HEATER AC UNIT WFB continued 1 2 2 Fig 3 548 04558 Schematic Fig 3 05 31 2019 Updated SERVICE...

Страница 114: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 118: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 124: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 133: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 134: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 138: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 172: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 181: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 182: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 184: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 194: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 207: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 208: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 210: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 215: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 216: ...THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 217: ...THIS PAGE LEFT INTENTIONALLY BLANK...