51

51

Noisy motor

Check motor bearings or loose fan

motor.

Drill or Tool Heats

up or Burns Work

Excessive speed.

Chips not clearing.

Dull tool.

Feed rate too slow.

Failure to use cutting oil or

coolant. (on steel.)

Reduce speed.

Use pecking operation to clear chips.

Sharpen tool or replace.

Increase feed enough to clear chips.

Use cutting oil or coolant on steel.

Drill Leads Off

No drill spot.

Cutting lips on drill off center.

Quill loose in head.

Bearing play.

Center punch or center drill work piece.

Regrind drill.

Tighten quill.

Check bearings and reseat or replace

if necessary.

Excessive Drill

Runout or Wobble.

Bent drill bit or tool.

Bearing play.

Drill not seated properly in

chuck.

Replace drill bit or tool. (Do Not

attempt to straighten.)

Replace or reseat bearings.

Loosen, reseat, and tighten chuck.

Work or Fixture

Comes Loose or

Spins

Failure to clamp piece part or

work holding device to table.

Clamp piece part or work holding

device to table surface.

Содержание DP-1000VS

Страница 19: ...16 16 OVERALL DIMENSIONS ...

Страница 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

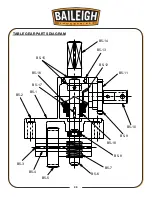

Страница 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

Страница 36: ...33 33 A20 7 A30 A17 2 A17 1 A17 A18 A18 1 A30 1 A20 9 A20 8 A9 1 A9 2 A20 6 A31 A32 A31 1 A20 5 A20 4 A20 2 ...

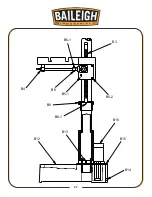

Страница 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Страница 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

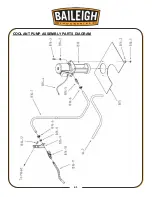

Страница 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Страница 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

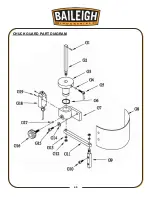

Страница 48: ...45 45 CHUCK GUARD PART DIAGRAM ...

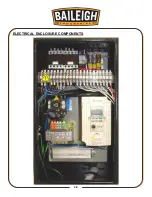

Страница 51: ...48 48 ELECTRICAL ENCLOSURE COMPONENTS ...