27

27

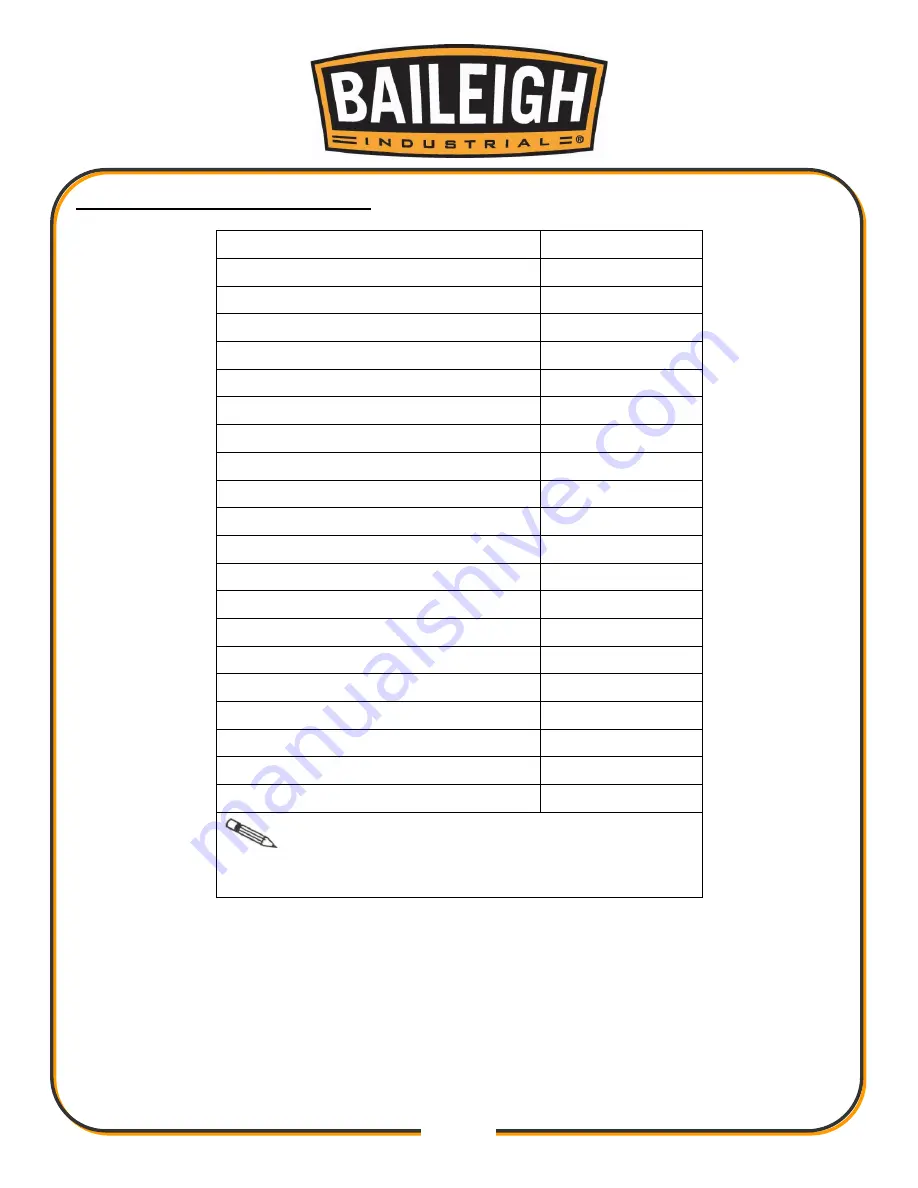

Speeds for High Speed Steel Drills

Material

Speed (SFPM)

Alloy Steel

— 300 to 400 Brinell

20-30

Stainless Steel

30-40

Automotive Steel Forgings

40-50

Tool Steel, 1.2C

50-60

Steel, .4C to .5C

70-80

Mild Machinery Steel, .2C to .3C

80-110

Hard Chilled Cast Iron

30-40

Medium Hard Cast Iron

70-100

Soft Cast Iron

100-150

Malleable Iron

80-90

High Nickel Steel or Monel

40-50

High Tensile Bronze

70-150

Ordinary Brass and Bronze

200-300

Aluminum and its Alloys

200-300

Magnesium and its Alloys

250-400

Slate, Marble, and Stone

15-25

Plastics and similar materials (Bakelite) 100-150

Wood

300-400

Titanium Alloys

10-25

Titanium Alloy Sheet

50

–60

Note: In cases where carbon steel drills are

applicable, the drill should be run at speeds of 40 to 50

percent of those given above.

Содержание DP-1000VS

Страница 19: ...16 16 OVERALL DIMENSIONS ...

Страница 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

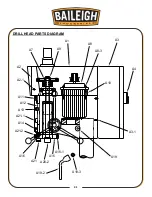

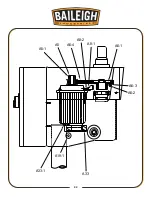

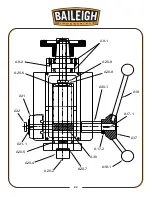

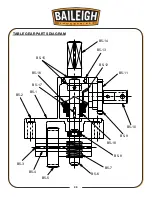

Страница 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

Страница 36: ...33 33 A20 7 A30 A17 2 A17 1 A17 A18 A18 1 A30 1 A20 9 A20 8 A9 1 A9 2 A20 6 A31 A32 A31 1 A20 5 A20 4 A20 2 ...

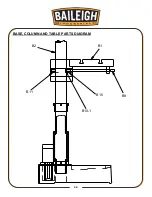

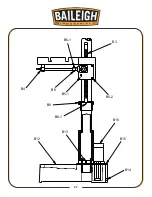

Страница 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Страница 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

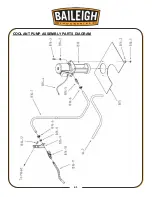

Страница 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Страница 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

Страница 48: ...45 45 CHUCK GUARD PART DIAGRAM ...

Страница 51: ...48 48 ELECTRICAL ENCLOSURE COMPONENTS ...